C. DRAIN COCK

G. REGULATOR AND PRESSI)RE CA('.E

The drain cock (figure 1) mounted on the underside

The regulator (figure 1) is a manually operated valve

of the air receiver tank is a manually operated valve used

controlling external air line pressure And may be

to drain compressed air and condensation from the air

adjusted within the range of 0 to 175 psi by turning the

receiver tank.

handle. A needle indicating, direct-reading, pressure

D. OIL I.EVEL GAGE

operated gage- graduated from 0 to 300 psi mounted in

The oil level gage mounted in the compressor

the regulator indicates regulator pressure setting.

crankcase ( figure 11) is a direct reading, glass covered

H. HAND-OFF-AUTOMATIC SFLECTOR SWITCH

gage used to check the level of the oil in the compressor

The hand-off-automatic: selector switch (figure 2) is

a manually actuated switch located front center of the

E. AIR RECEIVER TANK PRESSURE GAGE

magnetic switch box cover.

In OFF position the

The air receiver tank pressure gage (figure 1)

compressor motor will not operate(. When the selector

mounted on th4, side of the air receiver tank, is a needle-

is turned to AUTO position the compressor will operate

indicating, direct reading, pressure- operated gage

until pressure in air receiver tank reaches 175 psi then

graduated from 0 to 300 psi in increments of S psi. The

the pressure switch automatically shuts-off the motor.

gage indicates the air pressure in the air receiver tank.

The compressor will recycle again automatically when

Normal operating pressure is 140 to 175 psi.

pressure drops below 140 psi, and continue to cycle

F. SAFETY RELIEF VALVE

automatically in this AUTO position.

The safety relief valve (figure 1) is mounted in a tee

I. RESET BUTTON

fitting used to mount the air receiver tank pressure gage.

The reset button (figure 2) mounted on the cover of

It is a preset valve that is actuated when the air receiver

the magnetic starter, directly above the hand-off-

tank receives a pressure of 200 or more psi. This valve

automatic selector switch, is a manually operated button,

can be tripped manually by pulling up on the ring at the

which when pushed, resets the thermal relay in the

end. It is manually tripped to release pressure in the air

magnetic starter.

receiver tank and to test the valve.

SECTION IV

OPERATION UNDER USUAL CONDITIONS

2. Turn hand-off-auto selector switch (figure 2) to "off"

A. GENERAL

position.

The instructions in this section are published for the

3. Open the drain cock (figure 1) in the bottom of air

operation of the air compressor. It is essential that the

receiver tank to blow the compressed air and

operator know how to perform every operation of which

condensation from the air receiver tank.

the air compressor is capable. This section gives

4. Close drain cock.

instructions on starting and slopping, and air-pressure

adjustment.

D. AIR PRESSURE ADJUSTMENT

1. Start the air compressor (par. B above) to determine

B. STARTING

adjustment.

The pressure switch is preset by

1. Inspect the electric motor to make sure it is properly

manufacture at 140 psi CUT-IN, and 175 psi CUT-

wired from incoming power source and that power is

OUT setting. If adjustment is necessary shut off the

on.

outside power source.

2. Turn handoff-auto selector switch (figure 2) to "auto"

2. Remove cover from magnetic starter.

position.

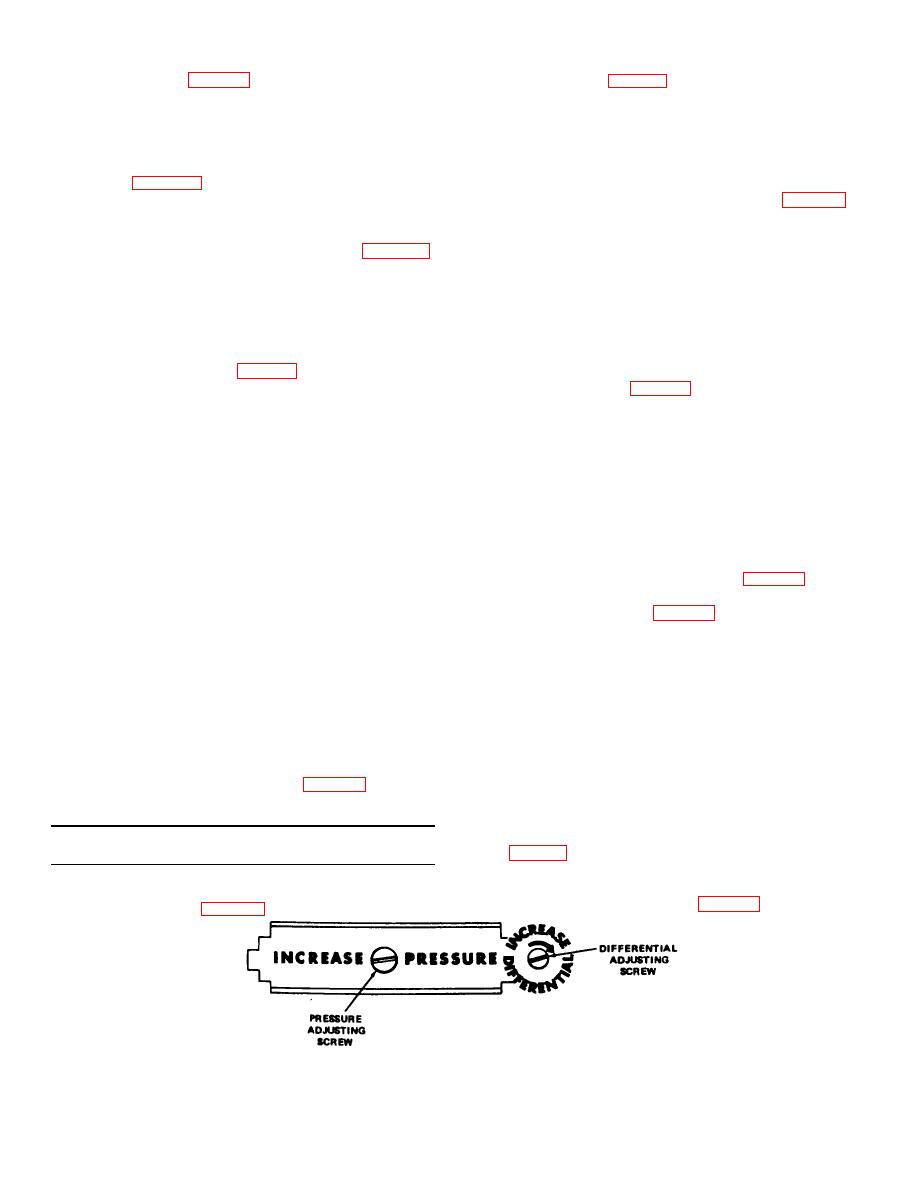

3. To raise the CUT-IN and CUT-OUT pressure turn

the pressure adjusting screw clockwise. Refer to

NOTE: Should the compressor fail to start, depress the

reset button.

4. To decrease the difference between the CUT-IN and

CUT-OUT pressure, turn the differential screw

C. STOPPING,

counter-clock-wise. Refer to figure 9.

1. Close globe valve (figure 1).

Figure 9. Pressure adjusting and differential screws.

7