TM 5-4310-349-14

CHAPTER 4

ORGANZATIONAL MAINTENANCE INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF MATERIEL

4-3.

Inspection and Servicing Equipment

4-1.

Unloading The Air Compressor

a. Make a thorough inspection of the air

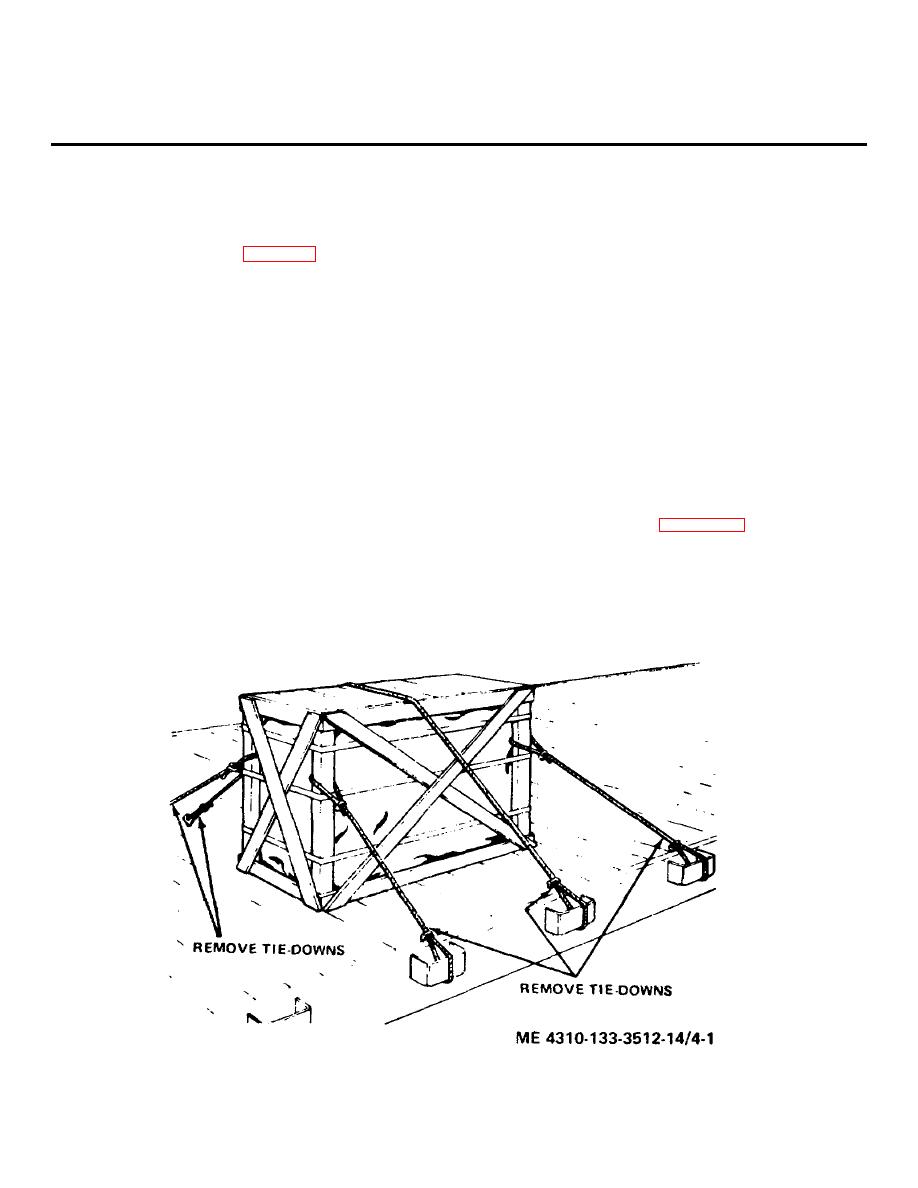

a. Remove tie-downs and blocking that secure

compressor for any loss or damage that may have

the crate to carrier. Refer to figure 4-1.

occurred during shipping or handling.

b. Inspect for dents, breaks, loose mounting

must be used when removing the air compressor from

bolts, or other defects. Inspect for loose connections,

the carrier. When using a hoist, center the lifting 'hook

damaged wiring, or other defects.

above the center of the crate; place slings about ten

inches in from both ends of the crate, and lift the unit

c. Turn the electric motor and compressor

from the carrier.

several times by hand to be sure the motor and

compressor do not bind. Prepare a written report of all

damage incurred as a result of shipping or vandalism.

4-2.

Unpacking The Air Compressor

Report any unrepairable damage immediately to the

a. Place the crated air compressor as close to

proper authority.

the point of installation as possible. Remove the crate

from the base being careful not to dam- age the air

4-4.

Installation

of

Separately

Packed

compressor while removing the crate. Remove the air

Components

hose, electric cable, tire gage, and publications.

Remove the compressor from the base

Connect air hose (figure 4-2) to globe valve

assembly and connect inflator gage assembly to air

b. Remove the tape and protective covering from

hose.

electric motor, compressor, and air receiver tank.

4-5.

Installation or Set-up Instructions

a. Location and Leveling.

Locate the air

compressor as near to the electrical power source as

Figure 4-1. Shipping tie-downs.

4-1