TM

5-4310-350-14

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

d. Use compressed air and remove all dust and dirt from pressure switch components then wipe

with a cloth dampened in an approved cleaning solvent

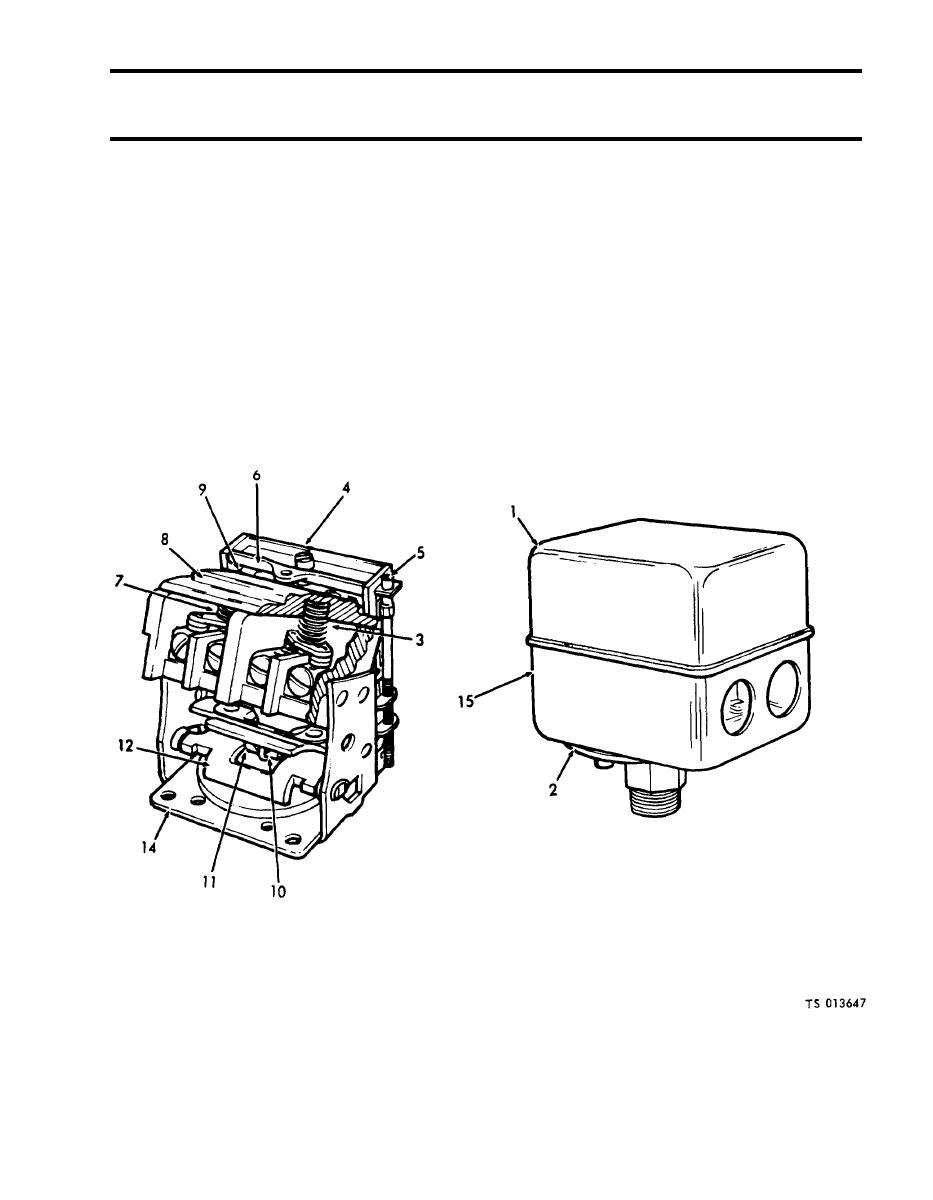

e. Using figure 5-5 as a guide disassemble the pressure switch assembly.

f. Remove the cover (1) pressure adusting screw (4) differential adjusting screw and nut (5)

top bar (6) spring equalizer- (8) main spring (9) conical spring (3) contact board assembly (7)

toggle spring (10) toggle (11) lever (12) plate diaphragm (13) diaphragm (2) frame assembly

( 14) and inclosures (15).

g. Inspect the contact board contacts (7) for pitting or burning. Use sand paper to remove pit-

ting or barring.

h. Inspect diaphragm (2) for cracks or breaks and general condition.

i. Inspect all threaded parts for damaged or defective threads.

j. Replace damaged or defective parts as necessarv.

k. Reassemble the pressure switch starting with the enclosure (15) then frame assembly (14)

diaphragm (2) plate diaphragm (13 ) lever (12) toggle (11) toggle spring (10) contact board

assembly (7) conical spring (3) main spring (9) spring equalizer (8) top bar (6) differential

adjusting screw and nut (5) pressure adjusting screw (4) and cover.

l. Install pressure switch assembly on air receiver.

m. Connect all electrical wiring.

n. Turn on outside power source.