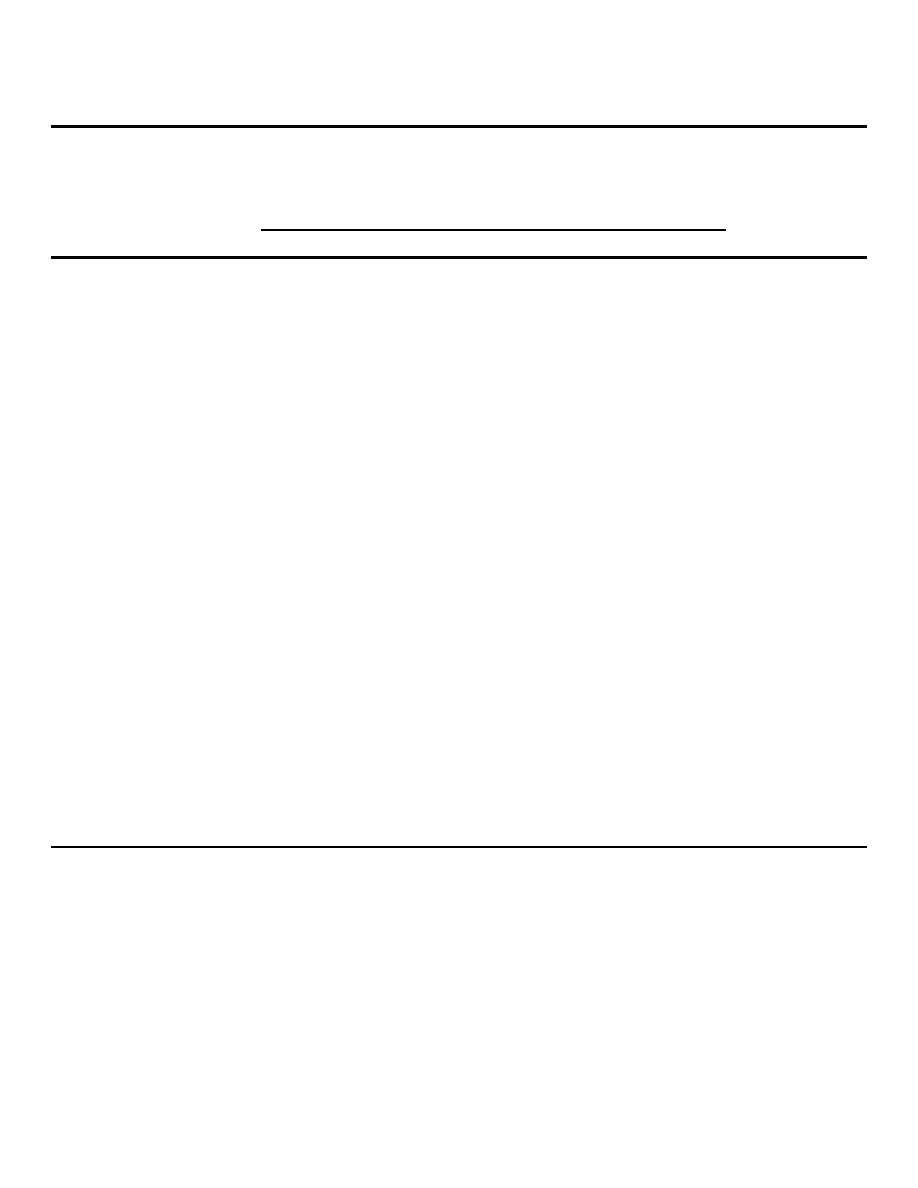

TM 5-4310-356-14

Table 5-2. Compressor Repair and Replacement Standards

Manufacturer'

s

Maximum

dimensions and

allowable

Component

tolerances in

Desired clearance

wear

U.S. and Metric

and

measurements

clearance

Minimum

Maximum

Minimum

Maximum

Cylinders

Bore, low pressure

4.6245

4.6255

0.004

(11.7462)

(11.7488)

(0.6350)

Bore, high pressure

2.4995

2.5005

0.002

(6.3488)

(6.3513)

(0.0008)

Out-of-round

0.001

(0.0025)

Taper

0.001

(0.0025)

Crankshaft

Journal (rod) size

1.623

1.625

(4.1149)

(4.1275)

Taper

(0.0025)

Out-of-round

0.005

(0.0127)

End play

0.000

0.002

(0.0051)

Pistons and Pins

Piston, low pressure

4.619

4.620

0.003

0.005

0.005

(11.7323)

(11.7348)

(0.0076)

(0.0127)

(0.0127)

Piston, high-pressure

2.4965

2.4975

0.0015

0.003

0.003

(6.3411)

(0.0076)

(0.0076)

Pin, low pressure

0.8125

0.8128

0.0000

0.0005

(2.0638)

(2.0645)

(0.0013)

Pin, high-pressure

0.8125

0.8128

0.0000

0.0005

(2.0638)

(2.0645)

(0.0013)

Bearings Connecting Rod

Bearing, I. D.

0.8125

0.8130

0.0901

0.007

(2.0606)

(2.0650)

0.0025)

(0.0178)

Bearing side clearance

0.010

0.017

(0.0254)

(0.0432)

NOTE

The manufacturer's dimensions and tolerances are given in U.S. and Metric

measurements. All Metric units are enclosed in brackets.

5-17