TM 5-4310-358-14

TS 4310-358-14/5-14

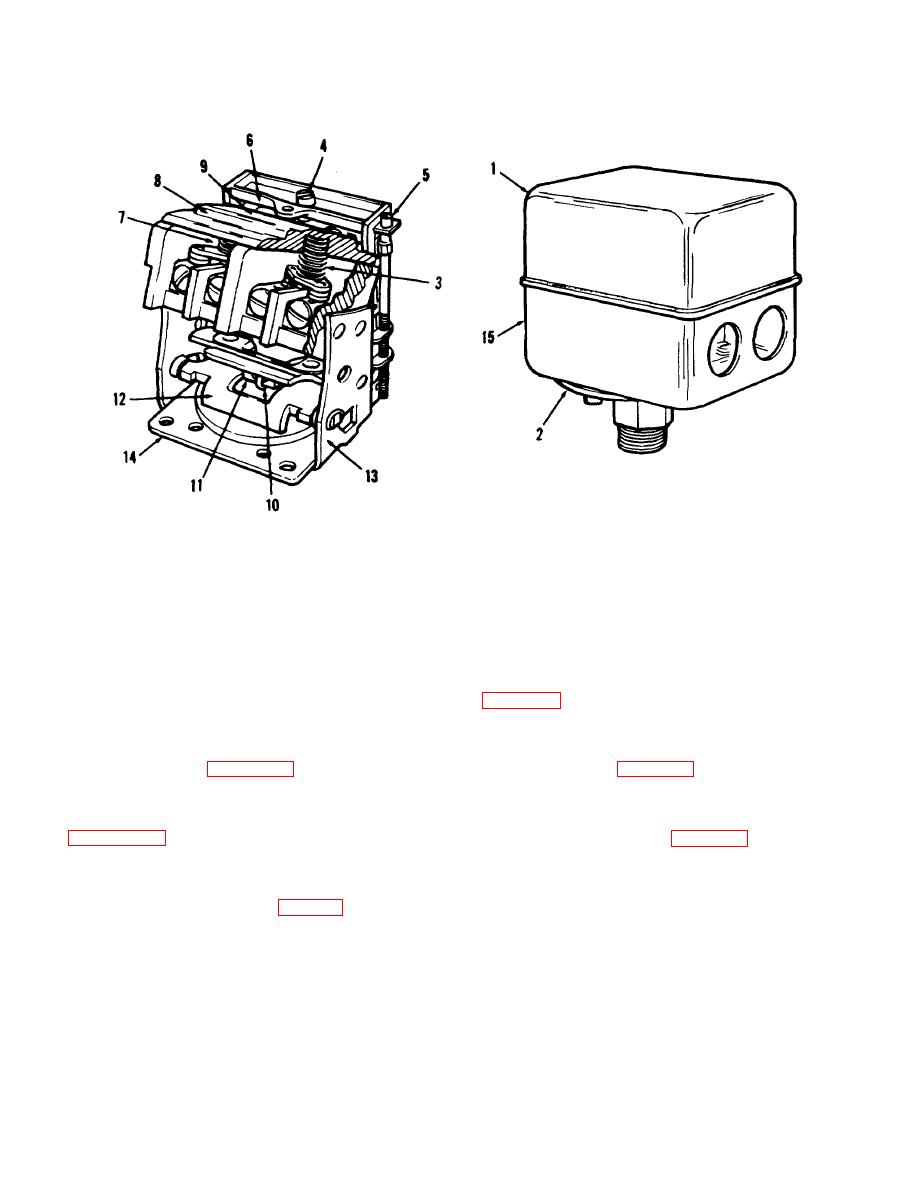

1.

Cover

6. Bar, top

11.

Toggle

2.

Diaphragm

7. Contact board assy

12.

Lever

3.

Spring, conical

8. Spring, equalizer

13.

Plate, diaphragm

4.

Screw, pressure adjusting

9. Spring, main

14.

Frame assembly

5.

Screw and nut, differential adjusting

10. Spring, toggle

15.

Enclosure

Figure 5-14. Pressure switch assembly.

(7), conical spring (3), main spring (9), equalizer spring

turn the pressure adjusting screw clockwise.

Refer to

(8), top bar (6), in frame assembly (14), securing with

differential adjusting screw and nut (5), and pressure

adjusting screw (4). Install cover (1).

d. To increase the difference between the CUT-IN

and CUT-OUT pressure turn the differential screw

clockwise. Refer to figure 5-15.

switch reversing the removal procedure.

e. To decrease the difference between the CUT-IN

(3) Set air pressure adjustment as des cribed

and CUT-OUT pressure, turn the differential screw

counter-clockwise. Refer to figure 5-15.

5-9. Air Pressure Adjustment.

CAUTION

adjustment.

The pressure switch is preset by

When adjusting the differential

manufacturer at 165 psi CUT-IN, and 190 psi CUT-OUT

screw, do not turn it farther than it

setting. If adjustment is necessary, shut off the outside

will turn easily.

power source.

f. To increase the differential and maintain the

b. Remove cover from pressure switch.

same CUT-OUT pressure, turn the differential screw

clockwise and, at the same time, turn the pressure

c. To raise the CUT-IN and CUT-OUT pressure

adjusting screw counterclockwise.

5-27