TM 5-4310-360-14

Section III. OPERATION UNDER USUAL CONDITIONS

2-4.

Assembly and Preparation for Use.

C.

Inspection and Service.

a.

Unloading.

Make a complete visual inspection of

(1)

the air compressor for any loss or

(1)

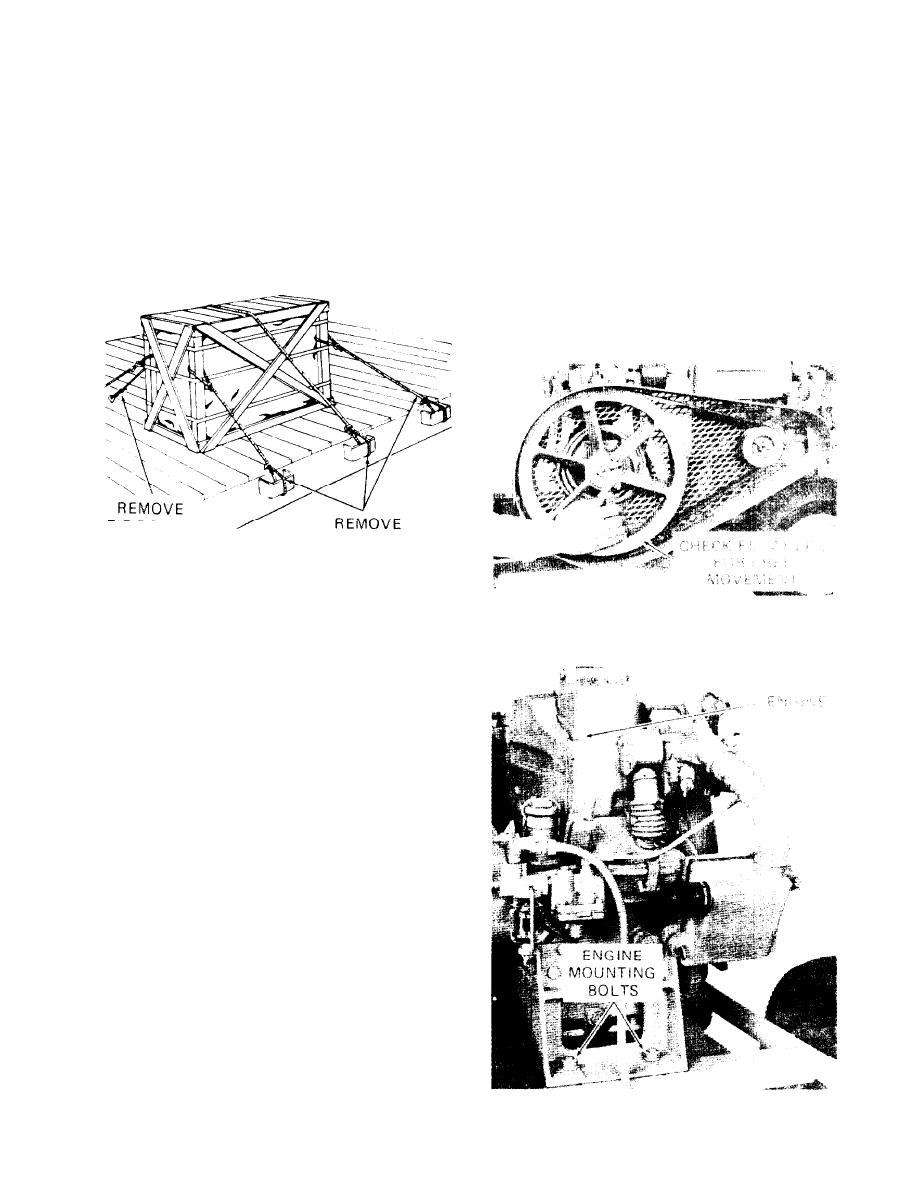

Remove all tiedowns or blocking that

damage that may have occurred during

secure the crate to the carrier.

shipment. See that flywheel pulley

turns freely by hand. If shipping crate

has been damaged, pay particular

attention to the compressor areas

adjacent to damage areas of the crate.

TIE-DOWNS

TIE-DOWNS

WARNING: Make certain any lifting

device used has a capacity equal to or

Inspect the engine for loose connec

(2)

greater than the weight being lifted.

tions, and insecure mounting.

Failure to observe this precaution

could result in injury or death to

personnel and damage to equipment.

(2)

A forklift truck, pipe rollers, or a suit-

able hoist must be used when removing

the air compressor from the carrier.

b.

Unpacking.

(1)

Place the air compressor as close to the

point of use as possible. Remove the

box containing the air hose assembly

and inflation device from the inside

of the crate.

(2)

Prepare the air compressor for inspec-

tion and servicing as outlined on DA

Form 2258, Depreservation Guide,

attached on or near the operational

controls.

(3)

Remove the nuts and lockwasher that

secure the air compressor to the

bottom of the crate and remove the

air compressor.

2-7