TM 5-4310-360-14

e.

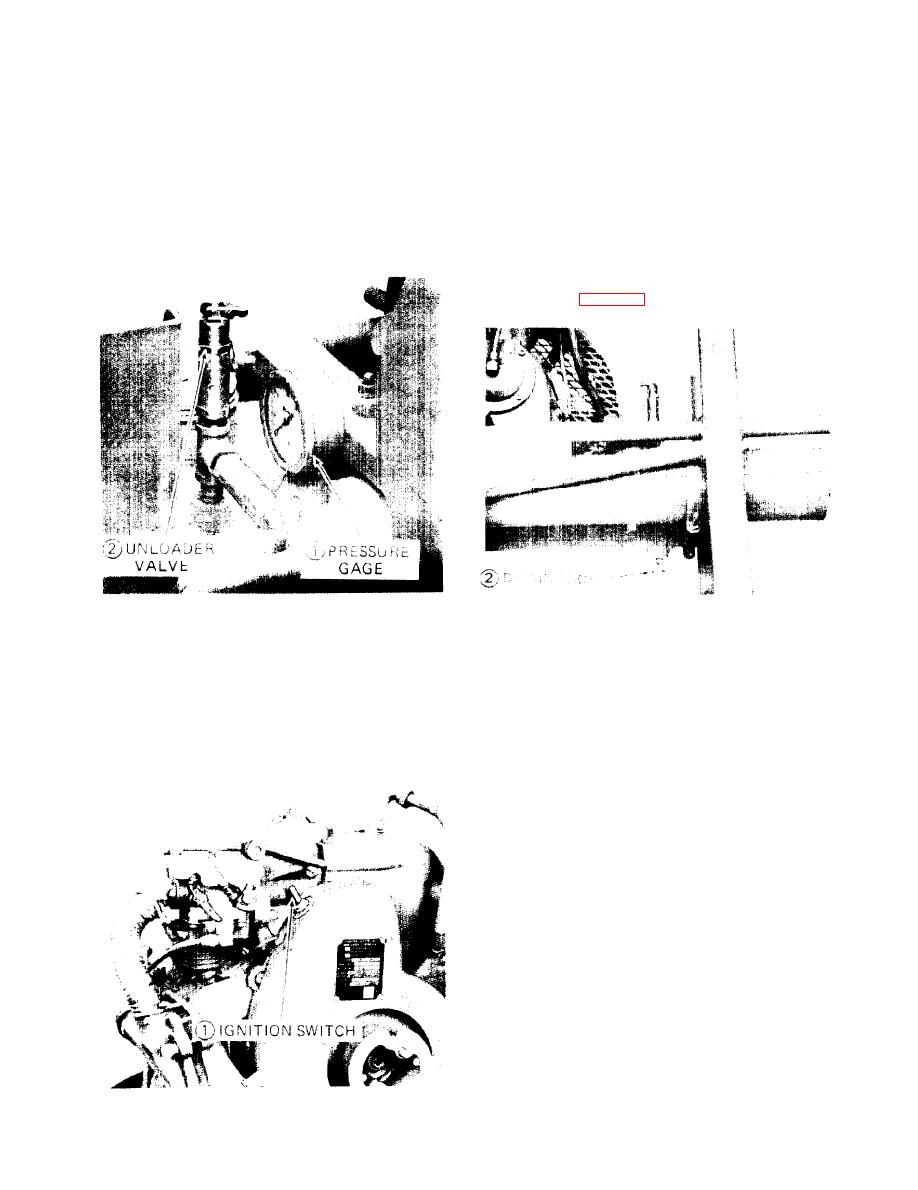

Stopping.

2-5.

Operating Procedure - continued.

Turn ignition switch (1) off.

(1)

d.

Operation.

Open draincock (2) to blow air and

(2)

(1)

Perform starting steps 1 through 11.

condensate from tank.

(2)

Check pressure gage (1) reading. It

(3) Close draincock.

should read between 140 to 175 psi

(9.8 to 12.3 kg/sq cm).

Perform the necessary After Opera-

(4)

tion Preventive Services as indicated

in table 2-1.

(3)

Unloader valve (2) is set to unload at

2-6. Preparation for Movement

175 psi (12.3 kg/sq cm). Replace

valve if valve does not unload between

Operate the compressor and allow the pres-

a.

170 and 180 psi.

sure in the air receiver tank to build to

approximately 100 psi (7.03 kg/sq cm).

NOTE: Air compressor will continue

to cycle as long as fuel is fed to the

b.

Stop the engine. Open the draincock and

engine.

blow the condensate from air tank. Close

the draincock.

Drain Fuel Strainer.

C.

Loosen the nut at the base of the fuel

(1)

strainer bowl retaining bail assembly

(1).

Swirly the bail to one side and care

(2)

fully lower the bowl (2) together with

gasket (3) and strainer (4). Empty the

bowl and discard gasket.

Position strainer (4) in recess of cover

(3)

(5) then place new gasket (3) and bowl

(2) over strainer.

Swing cup of bail assembly (1) beneath

(4)

bowl and secure with nut at base.

2-10