TM 5-4310-375-14

WARNING

Electricity is dangerous. Before performing any maintenance or adjustments,

be sure the electrical power is turned off. Never depend on the ON-OFF switch.

Turn power off at the source.

b. Maintenance. Turn main power off at the source. Unscrew the captive-type screw attaching pressure switch

cover and remove the cover. Inspect wire connections for tightness. Examine for evidence of shorts or burning of wire

insulation. Install pressure switch cover and notify direct support of any defect noted for repair or replacement.

4-18. Compressor assembly. Maintenance of compressor assembly at organizational level is restricted to removal and

installation and instructions contained in para 4-19, 4-20, and 4-21. Removal and installation is as follows:

WARNING

Drain air system before performing any maintenance. Open air receiver

drain cock.

a. Removal. Refer to para 4-14 and remove belt guard and drive belts. Refer to para 4-30 and remove air discharge

piping from aftercooler air outlet. Remove the air compressor assembly from the unit in following sequence.

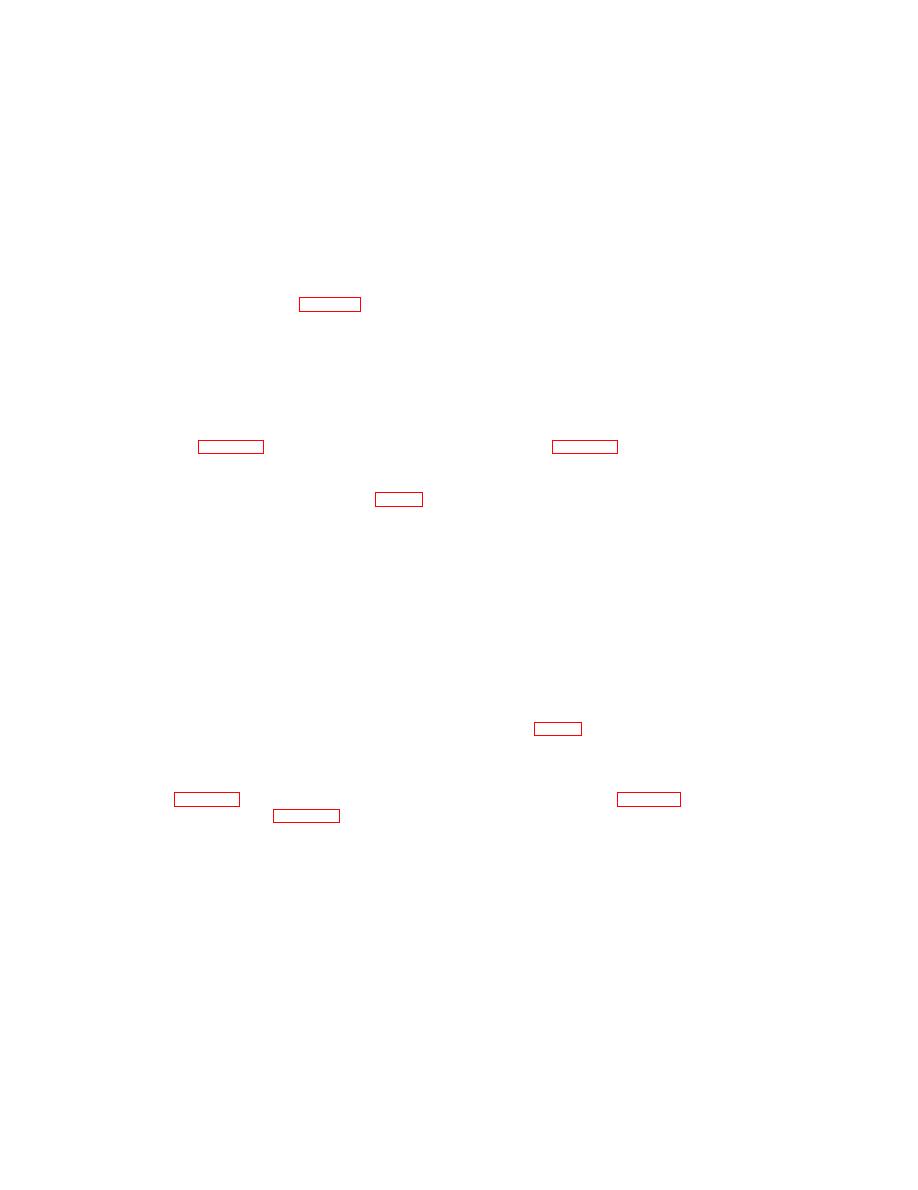

(1) Unscrew and remove the four locknuts (1, fig 4-5) and screws (2) attaching air compressor assembly (3) to

the air receiver saddle (4).

(2) Use a suitable sling and lifting device to remove air compressor assembly (3) from unit and place on a work

bench.

NOTE

Place wooden blocks under air compressor frame so the flywheel does

not rest on the bench.

b. Installation. Install air compressor assembly on air receiver saddle as follows:

(1) Use suitable sling and lifting device to set air compressor assembly (3, fig 4-5) on air receiver saddle (4).

(2) Secure the assembly (3) to saddle (4) with four screws (2) and locknuts (1).

(3) Refer to para 4-30 and install air discharge piping to aftercooler air outlet. Refer to para 4-14 and install drive

belts. Adjust drive belts as shown in figure 2-3; then install belt guard.

4-16