TM

5-4310-376-14

Table 5-1. Direct Support Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

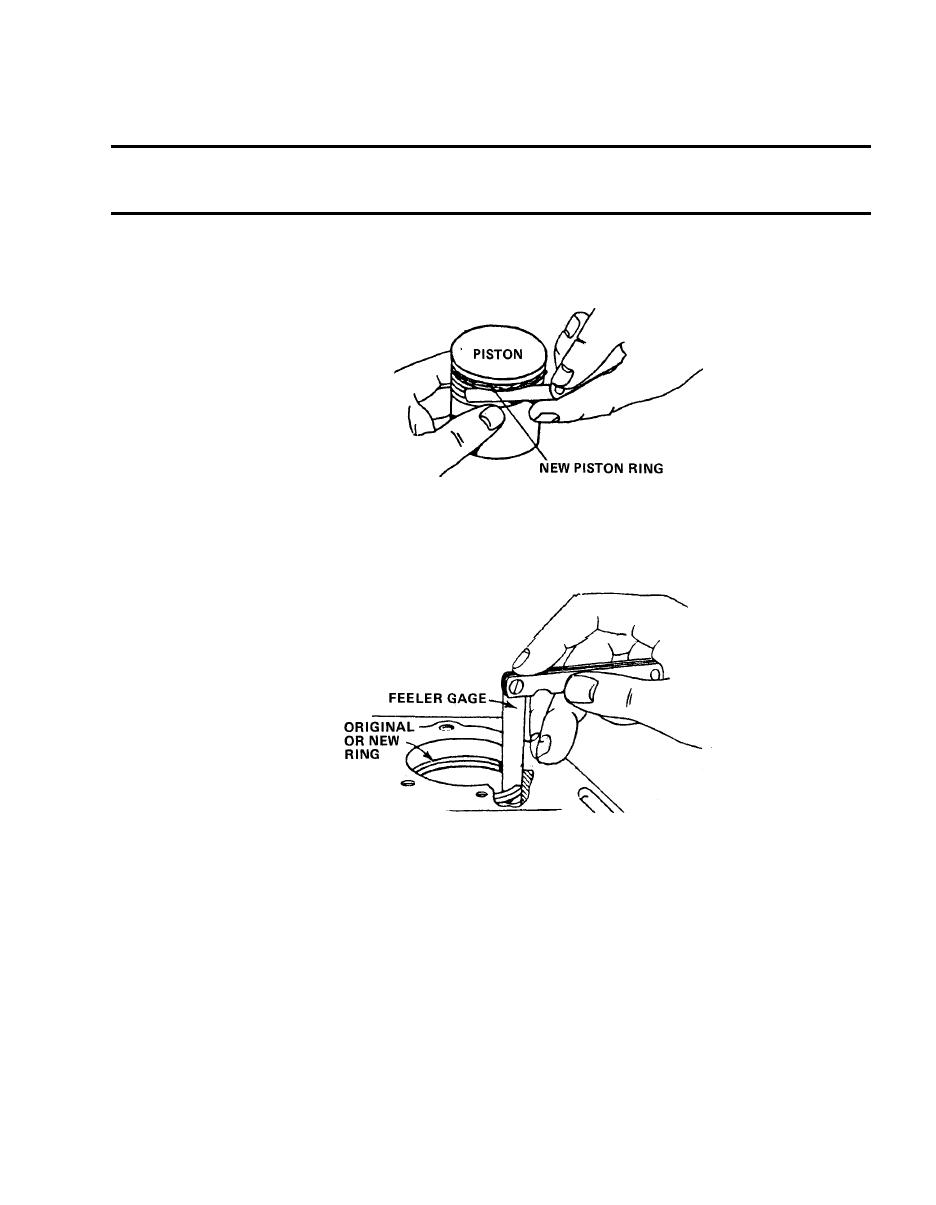

(1) Check piston - clean carbon from top ring groove, place a new ring in the

groove, check remaining space with a feeler gage. If a .007" (0.18mm) feeler

can be inserted, piston is worn.

Replace piston.

Check rings - Clean carbon from ends of rings and from cylinder bore. Insert

(2)

original rings, one at a time, one inch down into cylinder. Check gap with

feeler gage. If ring gap is greater than .035" (0.80 mm) for compression ring,

and .045" (.14mm) for oil ring, ring is not usable for replacement.

Replace ring(s).

Check connecting rod - If crankpin bearing in rod is scored, rod must be re-

(3)

placed. Rejection size of crankpin bearing hole is 1.252" (31.80mm). Do not

attempt to "file" or "fit" rod.

Replace connecting rod.

Check piston pin - Rejection size of piston pin bearing hole is .802" (20.37mm).

(4)

If piston pin is worn .0005" (.01mm), out of round, or below .799 (20.29 mm)

pin is reject.

Piston pins .005" (0.13mm) oversize are available in case connecting rod

and piston are worn at piston pin bearing. Replace piston pin.

5-3