TM 5-4310-376-14

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. ENGINE IS HARD TO START OR FAILS TO START.

Step 1. Remove cylinder head (para 4-33). Scrape and wire brush combustion deposits

from cylinder, cylinder head, top of piston and around valves. Use a soft brush

to remove deposits. Make the following checks:

a. Check cylinder head for warpage - Place a straight edge across gasket surface of

head. Using feeler gage, ensure distance is the same across entire surface. Check

gasket for leaks and/or damage.

Replace cylinder head (para 4-33).

Following check must be made with piston at top dead

center at end of compression stroke to be sure that both

valves are closed.

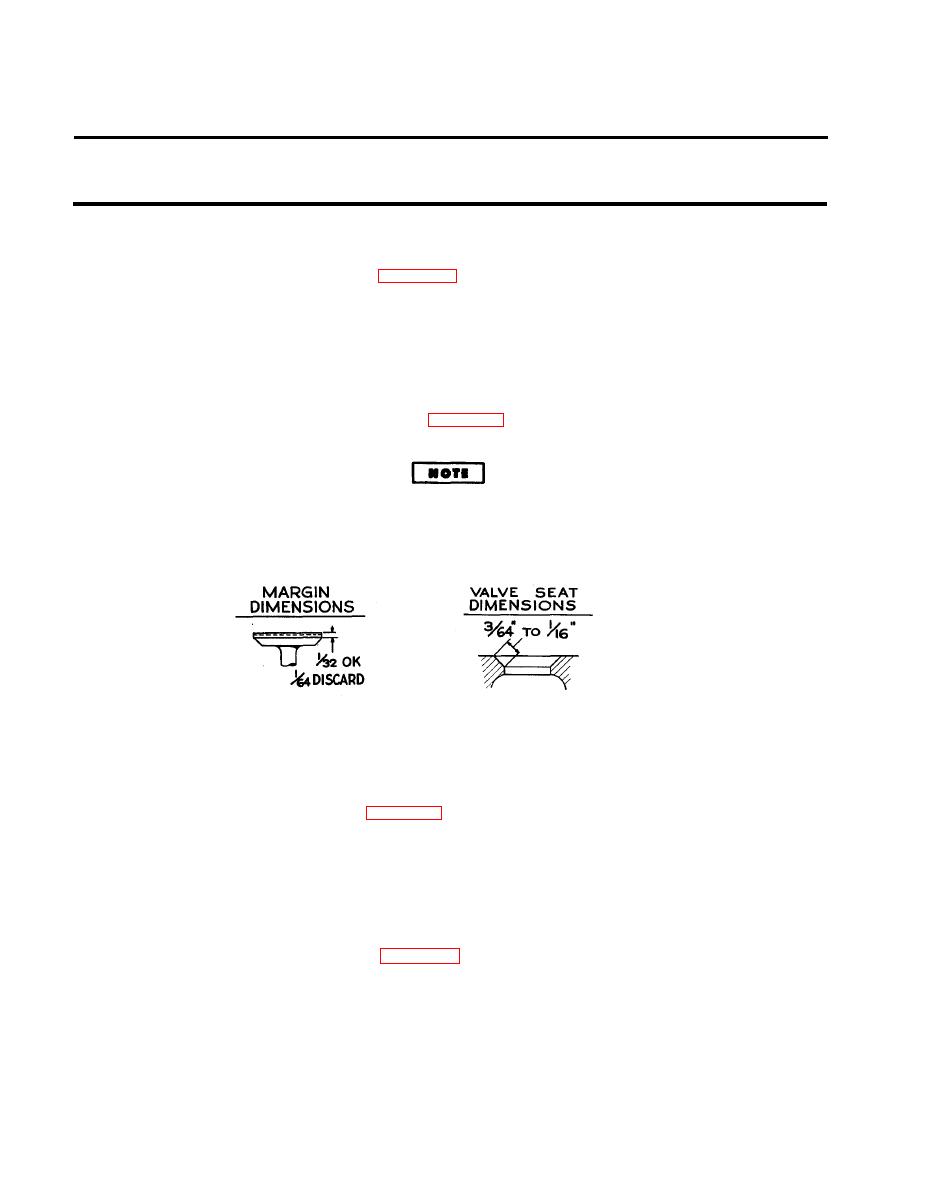

b. Inspect valves for seating dimensions as shown - valve margin should be 1/32"

(.8mm) maximum.

Replace valves (para 5-11), and/or seat(s).

c. Move piston to bottom of its stroke; inspect cylinder bore for roughness, scoring

or scruffing.

If evident, cylinder bore must be bored or honed oversize to eliminate

imperfections; smallest oversize piston must be used.

d. Remove crankcase cover (para 5-14). Remove piston and connecting rod (para

5-12) and remove piston rings. Make the following checks:

5-2