TM 5-4310-382-13

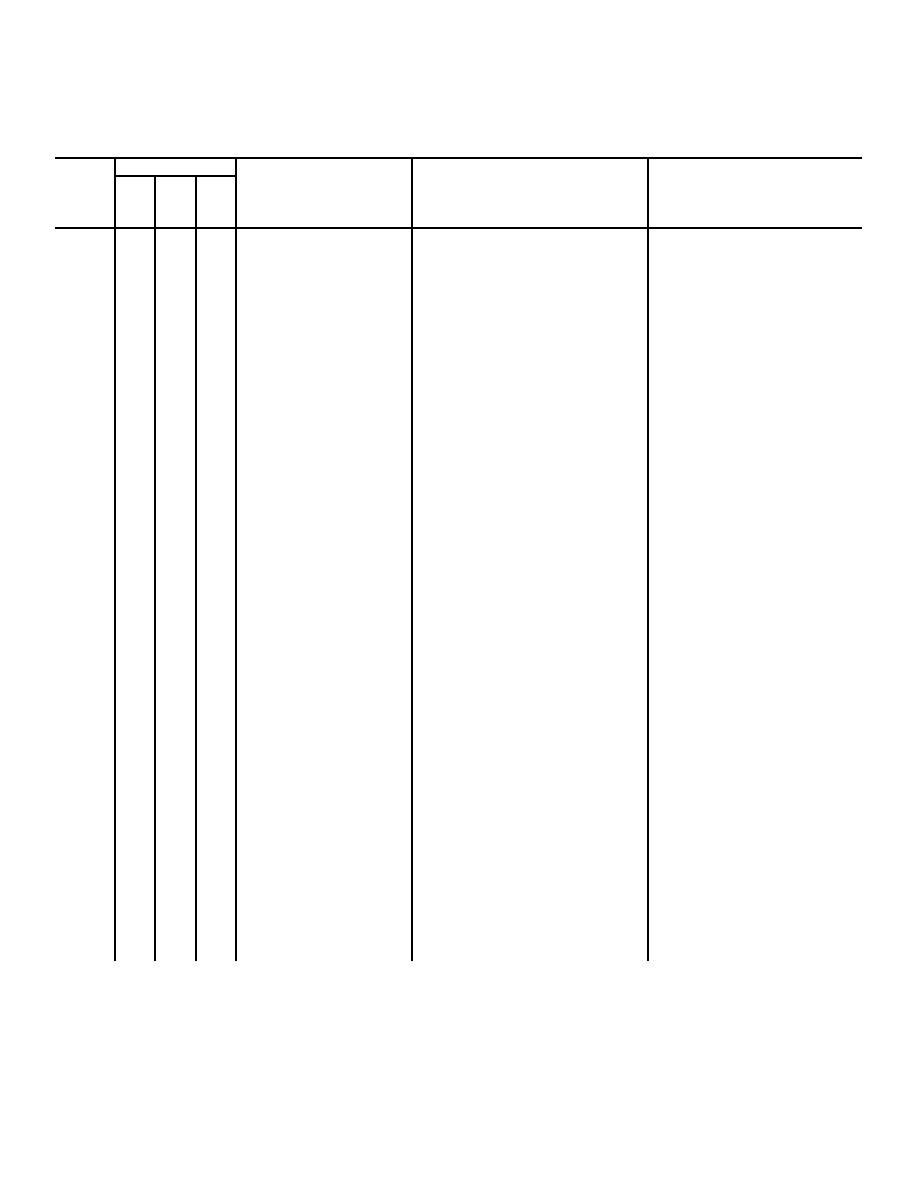

Table 2-1. Operator Preventive Maintenance Checks and Services

B - Before

D-During

A - After

Item

Interval

Item To Be

Procedure

No.

B

D

A

Inspected

Check for and have

Equipment Is Not

repaired or adjusted

Ready/Available If:

as necessary

1

Fuel Tank,

Inspect fuel tank,

Fuel tank, fuel lines,

Lines, Filter

lines, and fittings

or fittings are

and Fittings

for cracks and leaks.

cracked or leaking.

Examine all fittings

Fittings are loose.

for looseness. Check

Filter is

for clogged or dirty

clogged.

filter.

2

Belt Guard Assembly

Examine unit for missing

Belt guard is missing

belt guard. Inspect

or damaged in any way.

belt guard for

loose or missing

mounting hardware and

for breaks in guard

screen.

3

Belts, V,

Examine unit for missing,

Belts are missing,

Matched Set,

frayed or broken

frayed or broken.

and Guide

drive belts.

4

Take-Up Bolt

Inspect unit for missing

Take-up bolts

Assembly

or misadjusted

missing or out of

take-up bolt.

adjustment.

5

Air Cleaner

Examine foam pre-

Foam pre-cleaner is

(Engine)

cleaner for clogging.

clogged.

If pre-cleaner is

clogged, notify unit

maintenance.

6

Oil Gage Rod,

Check for missing oil

Oil gage rod is missing.

Tube, and Drain

gage rod. Inspect

Damaged tube.

(Engine)

tube for bends or dam-

Loose or missing

age. Inspect engine

drain plug.

for loose or missing

Improper oil level.

drain plug. Check

oil level on oil gage

rod for proper oil

level. Fill to proper

level with oil if

required.

2-5