TM 5-4310-382-13

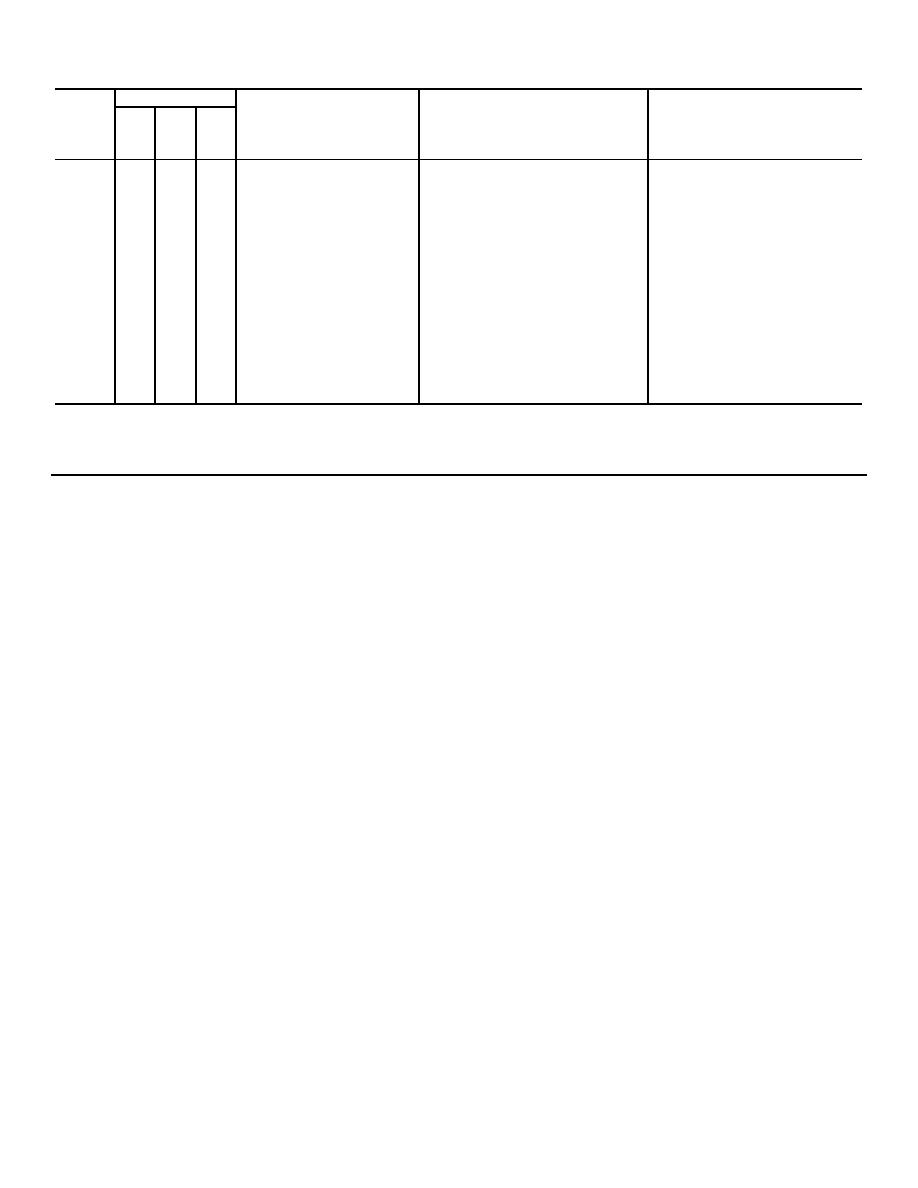

Item

Interval

Item To Be

Procedure

No.

B

D

A

Inspected

Check for and have

Equipment Is Not

repaired or adjusted

Ready/Available If:

as necessary

14

Air Gage

Check air gage for

Air gage is cracked,

dents, cracks, broken

glass is broken or

glass, loss of fluid,

fluid is lost. Air

or bent needle.

gage does not show

Start unit and inspect

proper pressure indications.

for proper pressure

indications.

15

Drain Cock

Inspect drain cock for

Drain cock is cracked,

cracks or looseness.

loose, or leaks air

Check drain cock for

pressure.

leaks when air tank

is under pressure.

Section III. OPERATION UNDER USUAL CONDITIONS

2-4. ASSEMBLY AND PREPARATION FOR USE. The air compressor unit is shipped as a completely assembled unit.

No further assembly of the unit is required before operation.

WARNING

Always use a lifting device having at least 600 pounds (272.4 kgs) lifting capacity

when lifting the air compressor. Injury or death to personnel can result from using

improper lifting equipment.

a. Unloading. The unit can be unloaded from transporting carrier by using any appropriate lifting device. Attach

lifting cables under receiver tank and use spreader bars as necessary to prevent unit from turning when lifted.

CAUTION

To prevent component damage do not lift unit by attaching cables to air

compressor, motor, or belt guard.

(1) Remove all blocking and tie downs securing unit to carrier.

(2) Lift unit from carrier and transport to installation sight.

2-7