TM 5-4310-393-14

a.

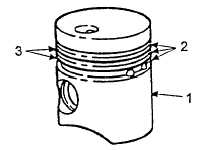

Clean piston (3) and wrist pin (Figure 5-39, Item 2) with dry cleaning solvent and dry with low

pressure compressed air.

b.

Remove carbon from piston ring lands and grooves.

c.

Clean inside surface of piston and piston skirt.

d.

Clean piston pin bore.

3.

Checking all the Parts

NOTE

Visually

inspect

all

piston

components. Take measurements as

indicated.

FIGURE 5-41. PISTON GROOVES

a.

Inspect piston, skirt, and piston grooves for excessive wear and damage Replace damaged piston.

NOTE

Excessively worn piston, rings or cylinder may be an indication of abnormal

maintenance procedures or operating conditions. Check for and correct any

abnormalities.

b.

Examine piston (Figure 5-41, Item 1) for scoring, fretting, pitting, cracks (especially on the interior

surfaces), damaged ring grooves, or for indications of overheating Repair slight scoring according to repair procedures.

Replace damaged piston.

c.

If piston is badly worn, check cylinder for excessive out-of-round, high spots, or other damage In

accordance with paragraph 5-6.5.

d.

Measure piston diameter (Figure 5-42, Item 1) along axis "A" and "B". A normal or new piston

diameter should be 2 8724 inches (72 96 mm) If piston is out-of-round, replace piston

5-33