TM 5-4310-393-14

adjust tension on the V-belt (see paragraph 3-14.2). When engine and compressor are in proper alignment, and V-belt

tension is correct, retighten the hold down bolts.

4-13.2. ENGINE CYLINDER HEAD AND VALVE ASSEMBLY.

This task covers: A. Inspect B. Adjust C. Check

D. Install

Tools:

Materials/Parts:

Tool Kit, General Mechanic's Set

Valve Cover Gasket (PIN 03208902

Torque Wrench

Equipment Conditions:

Engine Unit Shut Down and cold

A.

Inspect.

1.

Checking the Tappet Clearance.

a.

Rotate decompression lever clock-

wise until audible click is heard.

b.

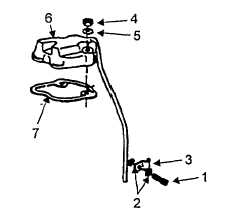

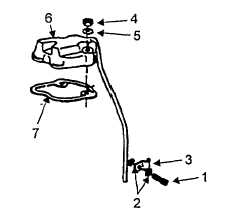

Loosen the screw (1) securing the

valve cover vent line clamp (3) with an open end wrench

(see figure 4-1).

c.

Remove valve cover retaining nuts

(4), and washers (5) lift off valve cover (6) and gasket

(7).

d.

Using the hand crank, turn engine

slowly in the direction of rotation until compression

resistance Is felt.

e.

Using a 0 004 inch (0.10mm) feeler

gauge, measure distance between rocker arm and valve

stem

f.

Tappet clearance is correct when

this measurement is 0.004 inch (0.10mm) when engine

is cold and there is a slight drag felt on the feeler gauge.

B.

Adjust.

1.

Adjusting

the

Tappet

Clearance

and

Decompression Mechanism.

a.

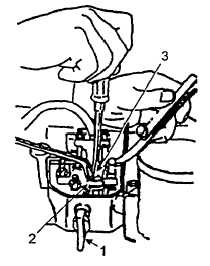

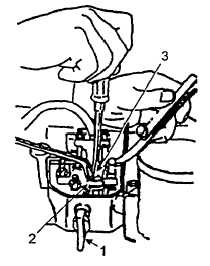

Put decompression lever (Figure 4-

2, Item 1) in the RUN position. See figure 4-3.

b.

Turn engine clockwise when facing

throttle control lever until compression resistance can be

felt.

Figure 4-1. Removing Valve Cover

Figure 4-2. Tappet Adjustment

4-12