TM 5-4310-393-14

a port at the base of the second stage cylinder. A sight glass is provided at the return port When oil pressure is properly

regulated, full oil flow is visible without bubbles. Adjustment of the lube oil pressure regulator is described in

paragraph 3-14.1. A plug in the top of the mounting flange provides a connection for a pressure gauge to check oil

system pressure Normal operating oil pressure is 850 psi ± 50 psi If proper oil pressure cannot be maintained by the

regulator, the unit must be replaced.

C. Replace.

1.

Replacing the Oil Pressure Regulator.

CAUTION

The regulator is internally spring loaded. Remove and disassemble with care.

a.

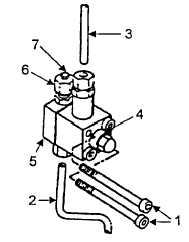

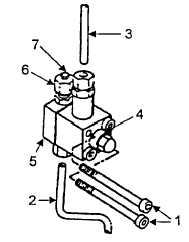

Remove inlet and return oil lines (

Figure 4-7, Items 2 and 3). Cap or plug open ends to

prevent contamination of the oil system

b.

Remove mounting socket head cap

screws (1) and remove the regulator (4) and O-ring (8).

c.

Install

O-ring

with

halo

carbon

grease into piston cylinder

d.

Install the regulator by attaching it to

the third stage cylinder with the socket head cap screws

as original.

e.

Reinstall the oil lines from the oil

pump and from the second stage cylinder

Figure 4-7. Oil Pressure Regulator

NOTE

Before the compressor is placed in service it will be necessary to check oil

pressure with a suitable pressure gauge.

f.

Remove the plug (7) from the gauge port, fitting (6) in the top of flange (5).

g.

Install a calibrated test pressure gauge, suitable for testing oil pressure in the range of 700 to 1000

psi (48.9 to 69 bar) The connector (6) is for 6mm L tube.

h.

With the compressor in operation, verify that oil pressure is normal and the regulator is properly

adjusted in accordance with paragraph 3-14.1.

2. Oil Lines

a.

The oil lines provided with the model CAPITANO-PD are available as assemblies. In case of damage

they should be replaced as assemblies The oil lines consist of a supply line between the oil pump and the oil pressure

regulator, and a return line from the oil pressure regulator to the second stage cylinder. Each is fabricated of 6 mm OD

tube, shaped to fit the configuration of the compressor. The supply line includes a filter which is an integral part of the

line.

4-17