TM 5-4310-393-14

b.

Remove the selected oil line by releasing the tube end fittings and removing the oil line

c.

Cover or plug the opened fittings to avoid entry of dirt into the compressor oil system.

d.

Replace the oil line in the reverse order of removal

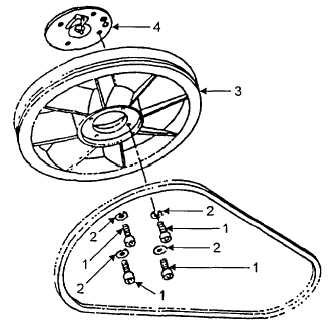

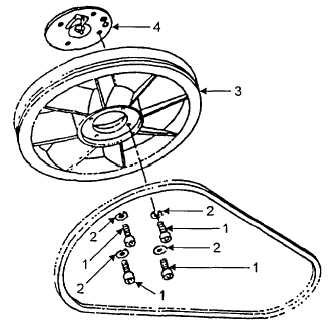

4-14.3. COMPRESSOR IMPELLER/GROOVE PULLEY

This task covers: A. Inspect b. Remove C. Repair D. Install

Tools

Materials/Parts:

Socket Wrench, N04447

Equipment Conditions:

Compressor Secures.

Belt Guard Removed

A. Inspect.

1.

Inspecting the Compressor Impeller/Groove Pulley

a.

Remove the drive V-belt and clean the flywheel with a stiff brush.

b.

Inspect the belt groove If the groove is worn so that the belt bottoms in the groove, the

impeller/groove pulley must be replaced.

c.

Inspect the Impeller blades for cracks or other damage. If damage is present, replace the

component.

B. Remove.

1.

Removing

the

Compressor

Impeller/Groove Pulley.

a.

Remove

four

socket

head

cap

screws (1) and lock washers (2) to separate Impeller (3)

from hub (4)

C.

Repair.

1.

Repairing

the

Compressor

Impeller/Groove Pulley.

a.

Only minor repairs such as cleaning

and removing dirt deposits and corrosion from the

Impeller blades and belt groove are practical. If physical

damage to the assembly exists, replace it.

D.

Install

1.

Installing the Compressor Impeller/Groove

Pulley.

Figure 4-8. Compressor Impeller/Groove Pulley

4-18