TM 5-4310-451-14

1-14. AIR COMPRESSOR ASSEMBLY (Con’t).

(6)

A safety relief valve, located within the separator

discharge check valve (12), is set to open if the oil

separator (1) pressure exceeds 140 psi (965 kPa). A

temperature switch will shut down the air compressor

unit if the discharge temperature reaches 240°F

(116°0C).

(7) Oil is added to the oil separator (1) through a

capped oil filler. An oil level gage enables the operator

to visually monitor the oil separator oil level.

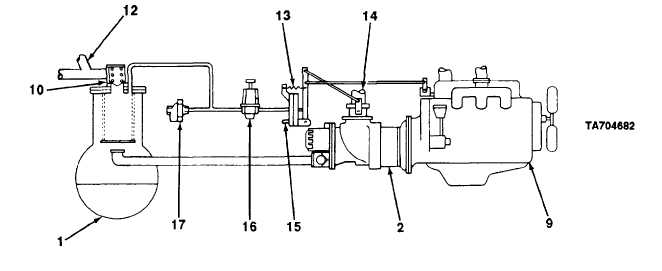

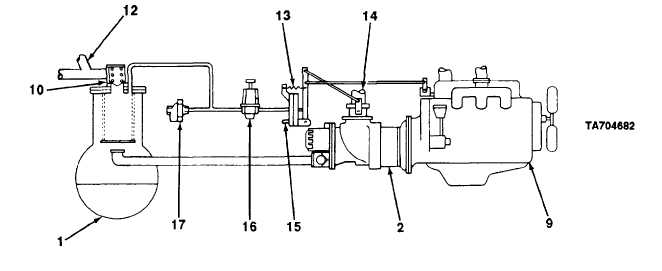

d. Control System. The purpose of the control system is to regulate the amount of air intake In accordance with the

amount of compressed air being used. The control system consists of a sullicon control (13), pressure regulating valve

(16), blowdown valve (17), and link rods which connect the sullicon control to the inlet valve (14) and engine (9) governor.

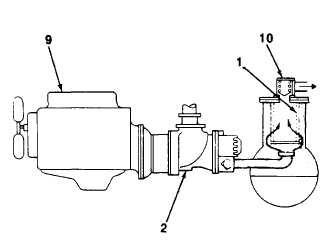

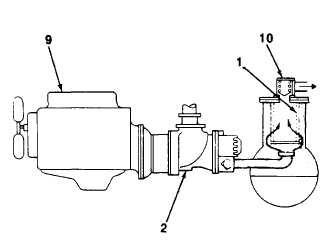

(1) During startup the pressure regulating valve (16) and the sullicon control (13) are Inoperative. When the air

compressor unit is started, the oil separator (1) pressure will quickly rise from 0 to 40 psi (0 to 276 kPa). The spring on the

sulllcon control holds the butterfly valve fully open and the air compressor assembly operates at full rated capacity. As the

air compressor assembly operates at full capacity, the engine (9) runs at full speed. The rising oil separator pressure is

Isolated from the service line by the minimum pressure valve (10) which is set at approximately 40 psi (276 kPa).

(2) When the oil separator (1) pressure rises above 40 psi (276 kPa), the minimum pressure valve (10) opens and

delivers compressed air to the service line. The sullicon control (13) remains inoperative, holding the inlet

valve (14)

fully open for maximum air output. The engine (9) will continue to run at full speed.

1-16