TM 5-4310-451-14

5-29. CYLINDER HEAD REPAIR (Con’t).

3.

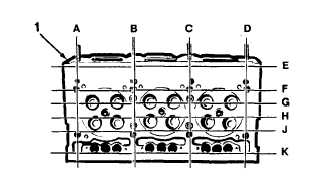

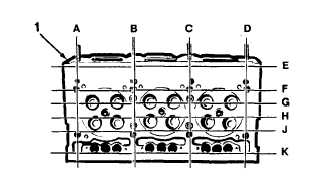

Aline straightedge along lines A, B, C, and D on

cylinder head (1).

4.

Using feeler gage, measure for warp at points

where lines E, F, G, H, J, and K intersect

straightedge.

5.

Warp measurement In step 4 must not be larger

than 0.004 in. (0.102 mm) at any point. If warp

exceeds limit, replace cylinder head.

6.

Aline straightedge along lines E, F, G, H, J, and

K on cylinder head (1).

7.

Using feeler gage, measure for warp at points where lines A, B, C, and D intersect straightedge.

8.

Warp measurement in step 7 must not be larger than 0.0055 in. (0.1397 mm) at any point. If warp exceeds limit,

replace cylinder head.

c. ASSEMBLY

NOTE

Right and left bank cylinder heads are assembled same way. This procedure covers one cylinder head.

1.

Install three plates (11) and new gaskets (12) on cylinder head (1) using six screws (9) and new lockwashers (10).

2.

Install two cover plates (14) and new gaskets (13) on cylinder head (1) using four screws (16) and new

lockwashers (15).

TA704943

5-62