electrolyte to a level in. below filler holes. Refer to

c. Lifting the Equipment.

TM 9-6140 -200-15 for complete servicing of wet

(1) Remove the tie down cables and blocking (fig.

batteries.

2-1) which secure the equipment to the carrier bed

WARNING

(2) Attach a suitable lifting device with a capa-

When servicing batteries, do not smoke or

city of at least 6,000 lbs. and remove the lubricating

use an open flame in the vicinity. Batter-

unit from the carrier bed as illustrated in figure 2-1.

ies generate hydrogen, a highly explosive

2-2. Inspecting and Servicing Equipment

gas.

g. Lubricate the unit in accordance with LO 5-4930-

a. Refer to TM 5-2805-203-14 and perform the

engine daily preventive maintenance services.

207-12.

2-3. Installation of Separately Packed Com-

b. Perform the lubricator and trailer preventive

maintenance services (para 3-7).

ponents

a. The batteries for the unit may be shipped dry-

c. Make a complete visual inspection of the lubri-

charged. The electrolyte for filling the batteries is

cating and servicing unit for loss, damage or pil-

shipped in separate containers. Fill the batteries with

ferage of components.

electrolyte until the level is in. below the filler

d. Inspect the lubricator for damaged enclosure

holes. Recharge batteries after filling with electrolyte

and doors. Inspect all components for proper and

when shipped dry charge.

secure mounting.

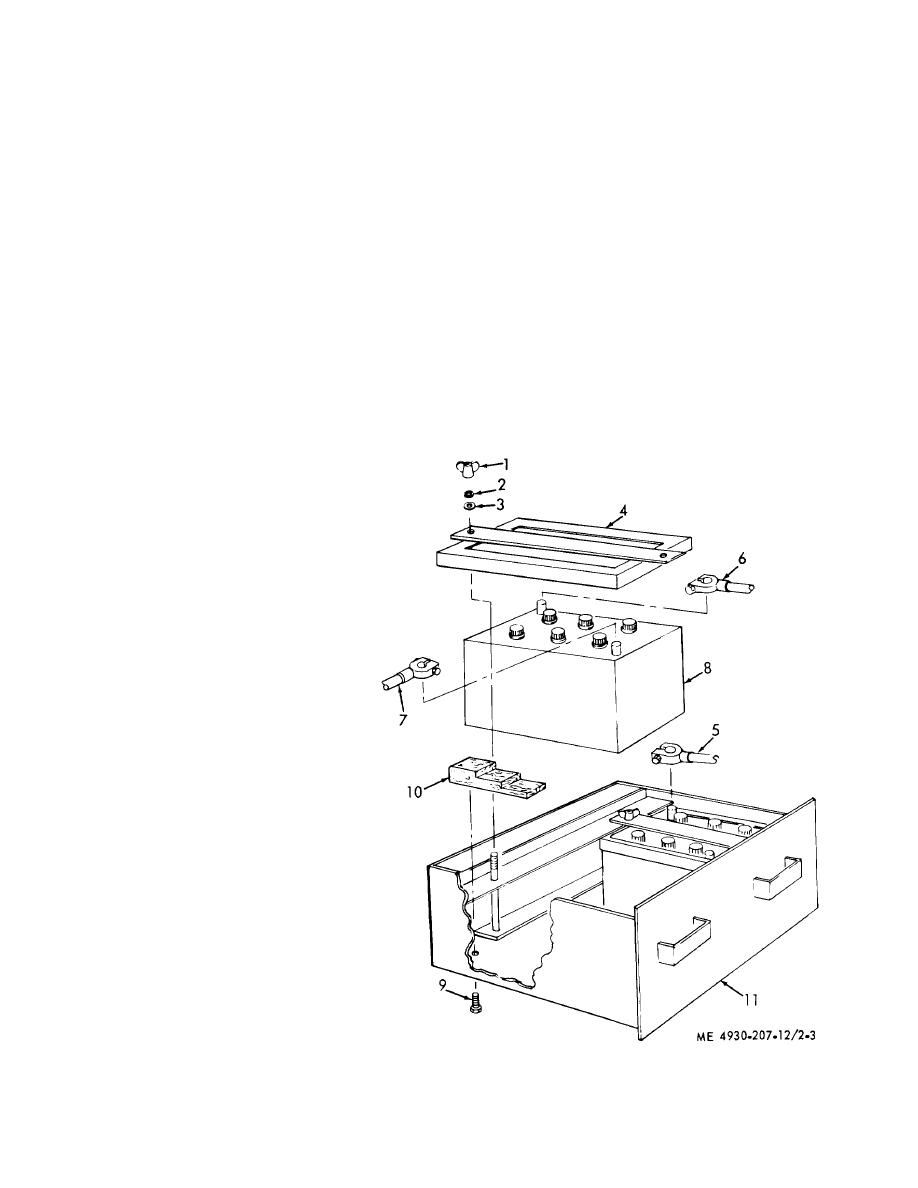

b. When batteries are filled, remove thumb nut (1,

e. Make sure all equipment shipped with the unit

fig. 2-3), washers (2 and 3) and clamps (4) and install

is undamaged and in a serviceable condition.

the batteries (8) in the battery drawer (11).

f. Remove caps from battery cells and fill with

l Thumb nut

2 Lockwasher

3 Flatwasher

4 Battery holddown clamp

5 Jumper cable

6 Positive cable

7 Negative ground cable

8 Battery

9 Wood screw

10 Battery spacer

11 Battery drawer

2-3