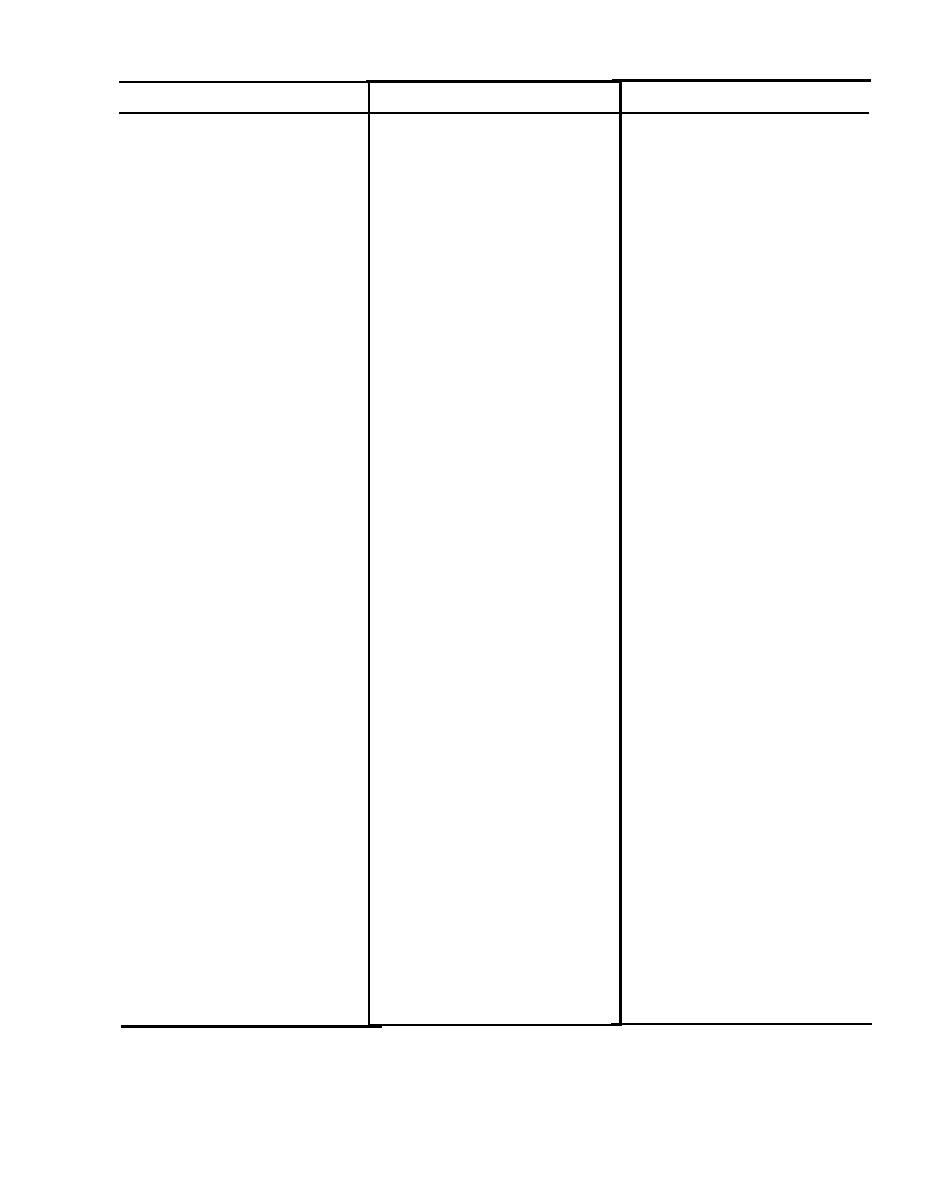

Table 3-2. Operator and Crew Troubleshooting

Corrective action

Probable cause

Malfunction

a. Inflate tires

1. Tires Wear Unevenly.

a. Tires not in-

flated to proper pres-

(para 1-4).

b. Tighten wheel

b. Loose wheels.

mounting bolts (para

4-36).

a. Provide adequate

a. Ventilation

2. Compressor Over-

ventilation around unit.

inadequate.

heats.

b. Compressor

thoroughly.

cooling fins dirty.

c. Refer to LO 5-

oil level.

4930-207-12 and add

oil to proper level.

d. Service the air

d. Dirty air

cleaner (para 3-18).

cleaner.

a. Refer to LO 5-

3. Compressor is

oil level.

4930-207-12 and add

Noisy.

oil to proper level.

b. Compressor V-

V-belts (para 3-17).

belts improperly ad-

justed.

a. Service air

a. Air cleaner

4. Compressor Pumps

cleaner (para 3-18).

dirty and clogged.

Too Slow or

Fails to Build

b. V-belts im-

b. Adjust V-belts

Up Pressure.

properly adjusted.

(para 3-17).

c. Refer to LO 5-

4930-207-12 and add oil

oil level.

to proper level.

d. Excessive

thoroughly.

dirt around compres-

sor cooling fins.

a. Replace V-

a. V-belts loose

5. Compressor V-

or too tight.

belts (para 4-19).

Belts Worn Ex-

cessively.

b. Replace V-belts

b. Oil or grease

on V-belts.

(para 4-19).

a. Refill lubricant

a. Exhausted lu-

6. Insufficient

bricant supply.

containers (para 2-13).

Pressure or

Volume with

b. Push grease down

Lubrication

b. Slow circula-

around pump intake prim-

tion of grease.

Pumps operating

ing tube and use exhaust

diverter to warm grease.

c. Set air regulator

c. Insufficient

to higher pressure (para

air pressure supplied

2-15). Check for closed

to pump.

or inoperative valves or

obstructions (para 2-14).

a. Replace filler

a. Leak at filler

7. Compressor Oil

cap.

cap.

Consumption is

High.

b. Other causes

b. Refer other causes

to Direct and General

Support Maintenance

personnel.

3-3