TM 5-4930-218-14

OPERATOR'S MAINTENANCE INSTRUCTIONS

S e c t i o n I. LUBRICATION INSTRUCTIONS

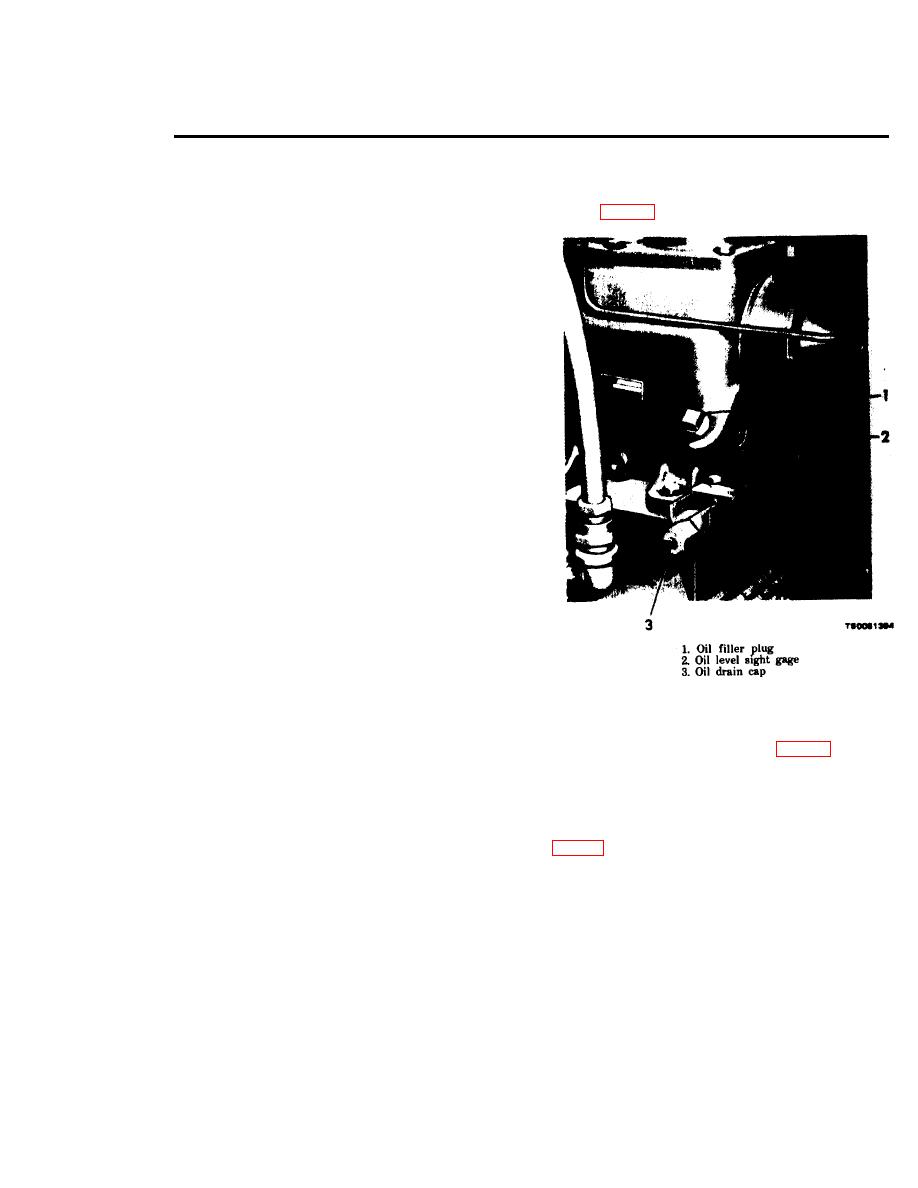

drain port before you remove the compressor oil drain

3-1. General

cap (3, fig. 3-1). Allow the oil to drain fully.

This section contains supplemental information

and lubrication instructions that the operator must

perform on the lubricating and servicing unit.

Lubrication Order LO 5-4930-218-12 will indicate to

you the required lubrication points, intervals, and

detailed instructions for the lubricating and ser-

vicing unit. TM 5-2805-203-14 covers engine

lubrication requirements.

a. Keep all lubricants in closed containers and

store in a clean, dry place away from external heat.

Allow no dust, dirt, or other foreign material to mix

with the lubricants. Keep all lubrication equipment

clean and ready to use.

b. Keep all external parts not requiring lubrication

free of lubricants. Before lubricating the equipment,

wipe all lubrication points free of dirt and grease.

Clean all lubrication points after you lubricate them

to prevent accumulation of dirt.

c. You must take the following precautions when

using a subzero engine oil in the compressor crank-

case:

(1) The crankcase oil level must be checked

frequently, as oil consumption may increase.

(2) The oil may require changing more frequent-

ly than usual because contamination by fuel dilution

and sludge formation will increase under cold

weather operation condition.

d. Service the air cleaner (see TM 5-2805-203-14).

c. Install the drain cap on the drain pipe.

Compressor crankcase lubrication consists

compressor crankcase and pour 2 quarts of engine oil

primarily of changing the oil in the crankcase.

into the compressor. You must use the oil required for

Proceed as follows:

the particular temperature range which will be en-

a. Run the compressor long enough to heat it to

countered. Refer to LO 5-4930-218-12.

operating temperature. This is important since warm

e. Check the oil level on the oil level sight gage (2,

oil will drain from the internal compressor parts

much more rapidly than cold oil. The warm oil will

low, add enough oil through the oil filler plug

also carry more dirt and sludge with it as it drains.

opening to bring the oil up to the proper level. Take

b. Place suitable containers under the compressor

care not to overfill.

Section II. PREVENTIVE MAINTENANCE CHECKS

AND SERVICES

it systematically so that defects may be discovered

3-4. General

and corrected before they result in serious damage or

To insure that the lubricating and servicing unit

failure. The necessary preventive maintenance ser-

is ready for operation at all times, you must inspect

3-1