TM 5-4930-218-14

do not spin the bearings. After cleaning, dip bearings

(3) Release all air from the inner tube and remove

into a container of clean engine oil and wrap them in

the tire (2) tube (3) from the wheel (4).

lint-free paper to prevent contamination by dust or

b. Cleaning and Inspection.

(1) Clean the tire, tube, and wheel with a

dirt.

(2) Discard and replace the grease seal (19) each

pressurized stream of water. Wipe any greasy or

gummy deposits from the wheel with a cloth dam-

time the hub and drum are disassembled.

(3) Clean all remaining parts with solvent and

pened with dry cleaning solvent (fed. spec. P-D-680).

(2) Inspect the tire for cracks, punctures, im-

dry thoroughly.

(4) Inspect the bearing cones for cracks, scored or

bedded foreign materials, cuts, and tears. Remove

foreign materials and skive around cuts to prevent

rough rollers or races, binding or catching operation,

or signs of overheating. Replace damaged bearing

them from tearing farther into the sound rubber of

the tire.

cones.

(3) Inspect the tube for deterioration, cracks,

NOTE

If either the bearing cones or cups are damaged, you

cuts, and leaks. If necessary, partially inflate the

must replace both parts as a matched set. Do not at-

tube and immerse it into a container of water to

tempt to use new cups with old cones or vice versa.

check for leaks. Patch any leaks.

(5) Inspect the bearing cups in the hub for scoring,

roughness, or other damage; if defective, press them

(2) on the wheel (4) and inflate to 50 psi. Check that

out or drive them out using a hammer and soft drift,

the tire retains its pressure. Secure the assembled

(6) Inspect the brake drum for cracks, wear,

tire and wheel to the lubricating and servicing

roughness, out-of -roundness, scoring, or other

assembly with six nuts (1). Lower the jack so that the

damage. Turn and grind the inside diameter of the

unit rests on the ground.

drums if defective.

(7) Check all shoulder bolts for looseness, cracks,

4-58. Wheel Hub and Drum.

and damaged threads. If damaged, drive out the bolts

a. Removal and Disassembly.

and drive in new ones. If the hole in the hub or drum

(1) Remove the wheel and tire (para 4-57a).

adapter is enlarged so that tight bolt mounting is not

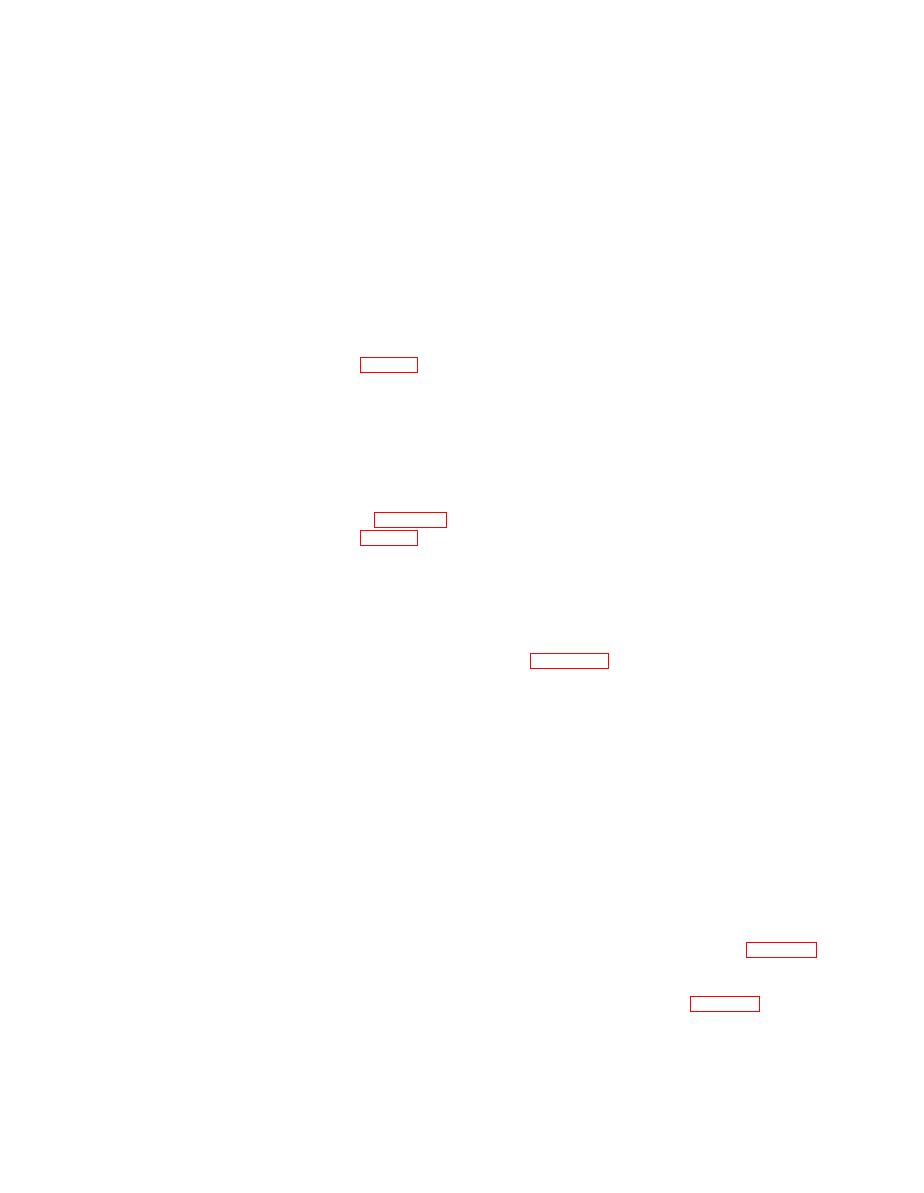

(2) Remove the three screws (5, fig. 4-19) and lock

possible, replace the hub or adapter.

washers (6) that secure the hub cap (7) to the wheel

(8) Inspect all other parts for cracks, distortion,

hub; remove hub cap and gasket (8).

damaged threads, and other damage; replace

(3) Bend up the tang of nut lock (10) and remove

damaged parts.

nut (9) and nut lock. Remove the bearing retaining

c. Reassembly and Installation.

nut (11).

(1) Reassemble and install the hub and drum in

(4) Remove six nuts (13) and remove the assem-

the reverse order of disassembly and removal. Refer

bled hub with bearings from the axle. Remove the

to figure 4-19.

outer and inner bearing cones (12 and 18) from the

(2) If bearing cups (15 and 16) were removed from

hub (17). Do not remove the bearing cups (15 and 16)

the hubs (17), press in new bearing cups squarely un-

from the hub unless inspection indicates that they

til they are fully seated in the hubs.

are damaged and must be replaced.

(3) During reassembly, pack the wheel bearings

(5) Remove the grease seal (19) and grease seal

with grease, following recommendations given in

sleeve (20) from the axle.

L.O. 5-4930-218-12.

(6) Disassembly of the brake drum (23) from the

(4) To provide proper bearing adjustment,

adapter (26) is not necessary unless either part is

tighten the nut (11) while rotating the wheel. Con-

damaged and requires replacement.

tinue to tighten until a distinct drag on the wheel is

felt, then back off the nut just enough to remove the

b. Cleaning and Inspection.

drag. Install the nut lock (10) and outer nut (9),

(1) If the bearings are in good condition and can

taking care not to upset the adjustment as the second

be reused, place them in a wire basket and flush them

nut is installed. Bend down one tang of the nut lock

up and down in a container of dry cleaning solvent

against a flat of the outer nut to lock the adjustment,

(fed. spec. P-D-680) to remove all caked and hardened

(5) Use a new hub cap gasket (8) when installing

grease. If necessary, rap the end sharply against a

the hub cap (7).

soft-wood block to dislodge the grease, Air-dry the

(6) Install the wheel and tire (para 4-57c).

bearings. If compressed air is used, take care that you

Section XVIII. TRAILER BRAKE SYSTEM

hydraulic system. Refer to figure 1-6. A dual system

4-59. Description

is used so that braking action will still occur even

a. The trailer brakes are operated by an air-over-