needle clockwise creates a leaner idling mixture; turning the needle counterclockwise makes the mixture richer. In the

double venturi system, the main venturi determines the maximum volume of air to be admitted into the engine, while the

secondary venturi is used to increase the suction on the high speed system and to aid in the complete atomization of fuel.

A power jet, or "economizer" controls the additional fuel required for maximum power at full throttle operation.

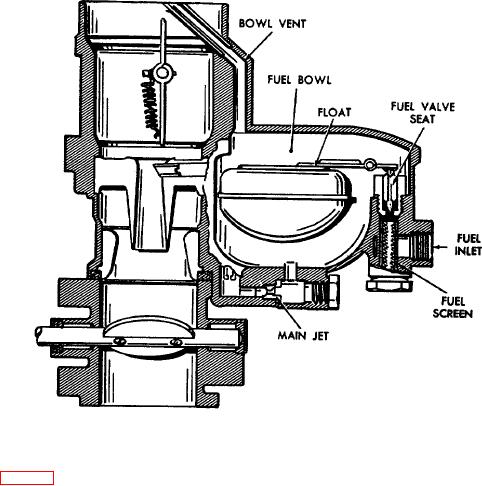

Figure 22. Cutaway view of carburetor.

b. Adjustment (fig. 23).

(1) Start the engine-compressor and allow it to run until warm. Then set the throttle stop screw for desired

idling speed. Idle speed should be between 500 and 700 rpm, and the speed at which the idle is actually set

should be that speed when a minimum amount of vibration takes place. It may be necessary to make a fine

adjustment of the throttle stop screw after adjusting the idle adjustment needle.

(2) the idle adjustment needle to obtain the smoothest possible idle of the engine. Turning the needle in (clock

wise) cuts off the flow of fuel and makes the air-fuel mixture leaner. Turning the needle out (counterclock-

65