f. Screw the fuel valve seat (19) and its fiber washer (20) into place, with the special valve seat wrench (par. 179).

Then place the fuel valve needle into the fuel valve seat with the knob end of the needle up.

g. Hold the free end of the float (15) and engage the knob end of the needle (19) with the slotted end of the float

lever. Lift the float and needle and slip the float axle (17) through the float lever; then lower the axle into the slots and the

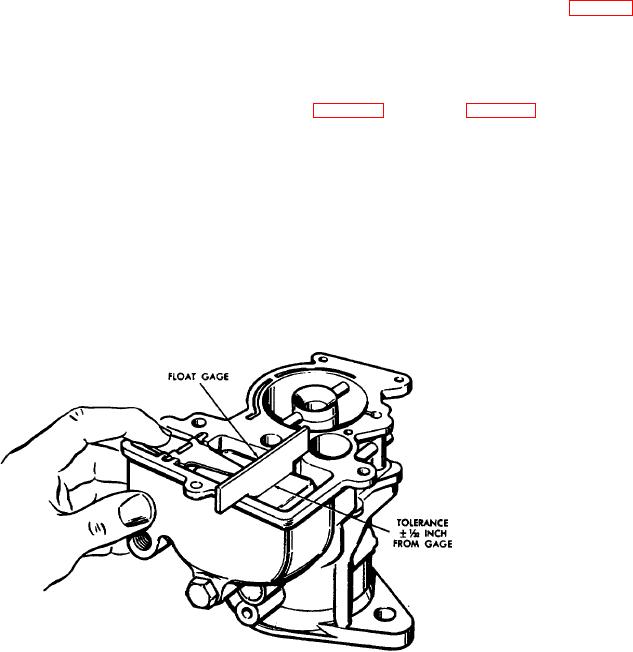

casting. Press down firmly on the float lever directly over the fuel valve and check the float for correct level. This float

level can be checked with the special Zenith carburetor float depth gage (par. 179) as shown in figure 74. A tolerance of

plus or minus 1/32 inch from the gage setting is permitted. Install the axle retainer plugs (16) with a flat end punch. Allow

approximately 1/64 inch tolerance above the machined surface.

h. Insert the well seal washer (10) down into its opening in the fuel bowl. Then install the check valve with jet (47)

open end down, into the same opening above the seal washer. The valve will extend approximately 1/64 inch above the

surface of the bowl casting.

i. Install the pump (49), guide (50), spacer (51), and pump spring (52), in that order, into the pump cylinder. Position

the bowl-to-intake gasket (12) on the fuel bowl. Then insert the vent and idle well (11) into the well on top of the bowl

gasket, and put the well seal washer (10) in place on top of the idle jet.

j. Place the air intake body (5) upright on a bench, with the bowl cover end toward the right. Hold the choke plate (6)

with

Figure 74. Checking carburetor float level.

174