TM 9-4310-397-14

Table 2-1. Preventive Maintenance Checks and Services for 16MS125 - Continued

Location

Item No.

Interval

Procedure

Not Fully Mission Capable If:

Item to

Check/Service

3

Before

ENGINE FUEL

Inspect ENGINE FUEL PRESSURE

PRESSURE Gauge

gauge (3).

a. Check for cracked or damaged

Cover lens damaged to

cover lens.

interfere with accurate

reading.

b. Check for cracks in case or

Crack in case, or class III

leaks.

leak found.

WARNING

Operating the rotary air com-

pressor with a damaged hose can

result in a hose rupture that could

cause serious personal injury.

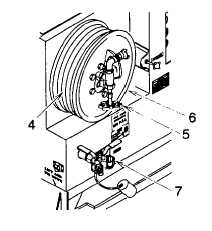

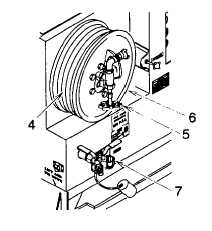

4

Before

Hose Reel

Inspect air hose (4).

a. Visually check hose for cuts,

Air hose is cut, cracked or

abrasions, cracks, and general

damaged to cause

condition of hose.

possibility of rupture.

b. Open and close valve (5) for

Valve binds.

smooth operation.

c. Unroll hose from reel (6) and

Hose reel binds or is

check for smooth operation.

excessively loose that

would cause leakage at

air seal.

2-9