TM 5-4310-354-14

TS5-4310-354-14/7-15 (2)

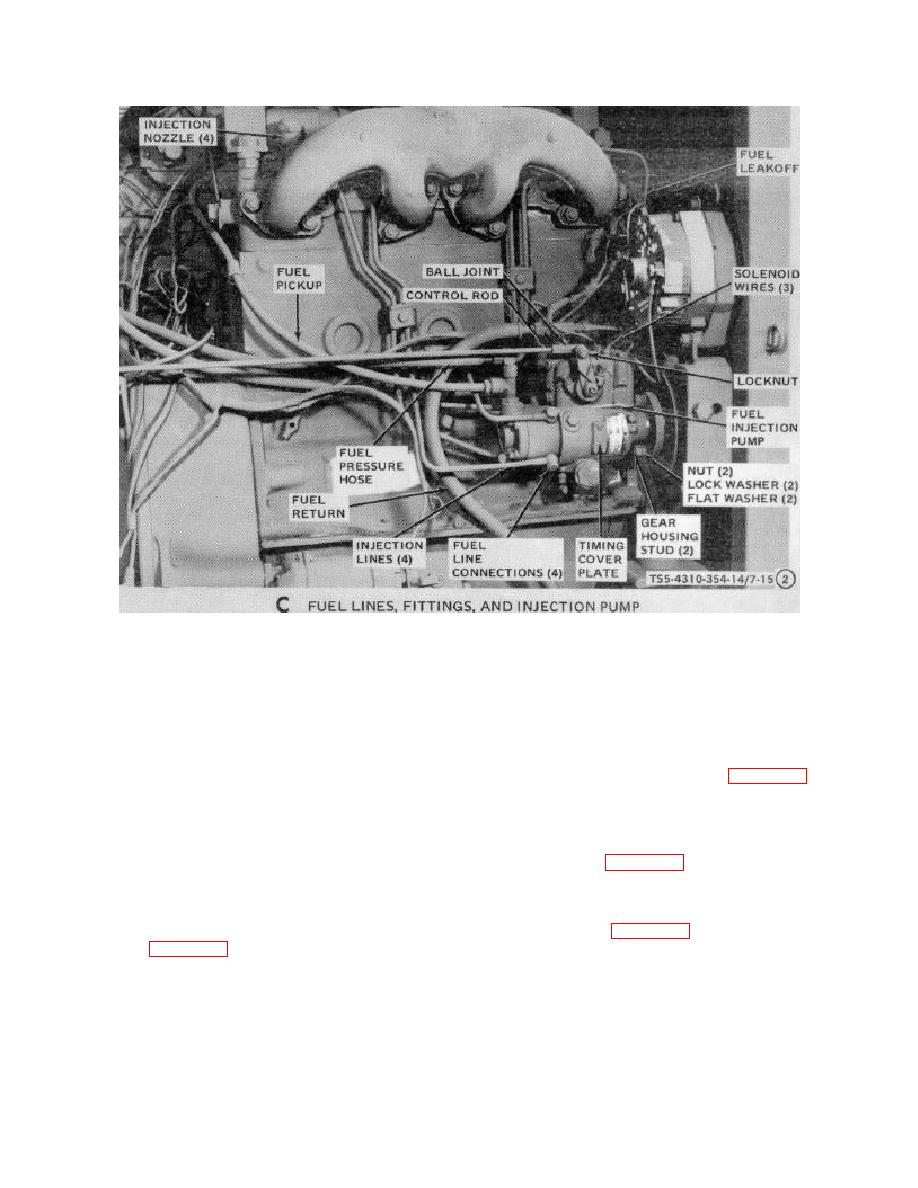

Figure 7-15. Fuel injection pump, removal and installation (Sheet 2 of 3).

(4) Check that number 1 cylinder is at 20 before

(5) Disconnect the fuel pickup hose, fuel pressure

top dead center. Determine this as follows:

hose, fuel return hose, fuel line leak off line, and

the four fuel injection lines from the pump.

(a) Remove injection nozzle from number 1

Reinstall the fuel connection screws and

cylinder. Place thumb over the nozzle

washers to prevent dirt from entering pump.

opening and feel for air being forced out

Remove all other fuel line fittings and plug the

during the compression stroke as the

fitting openings in the pump (figure 7-15).

engine is cranked.

(6) Remove lock nut from control rod swivel ball

(b) Check the timing mark on the flywheel in

joint and disconnect ball joint from pump lever.

relation to the timing mark on the fuel

Disconnect all wires from pump solenoid

injection pump. With fuel injection pump

terminals (figure 7-15).

timing marks aligned exactly, the exact

injection timing is indicated by the degree

(7) Remove cap screws, lock washers, thrust plate,

mark on the flywheel aligned with the

gasket, nut, lock washer, and injection pump

timing pointer. This degree should be 20

drive gear (figure 7-15).

7-17