TM 3-1040-263-34

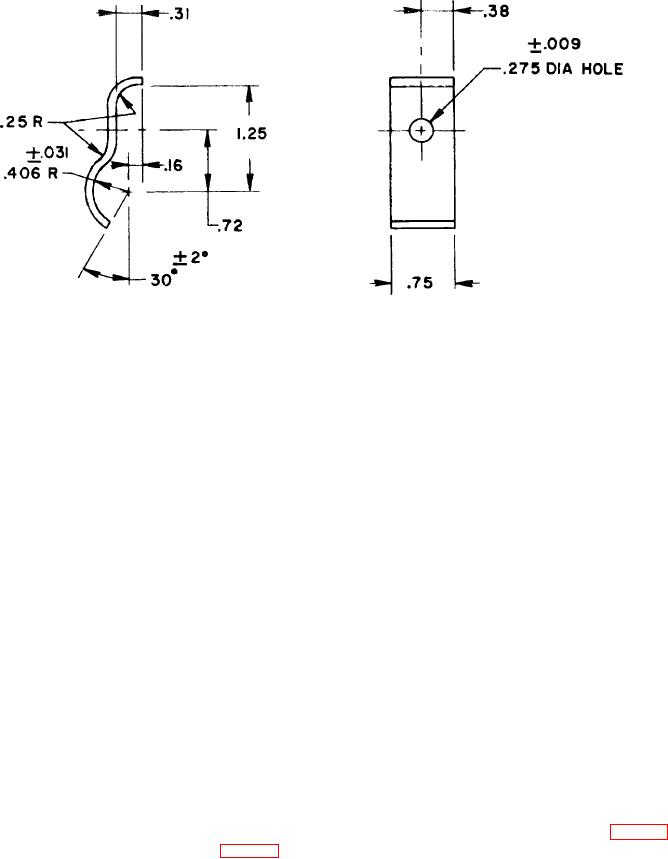

NOTES:

I. MATERIAL: ALUMINUM ALLOY 6061 SHEET TEMPER T6 0.090 INCH

NOMINAL STOCK THICKNESS SPECIFICATION QQ-A-250/11I

2. BREAK SHARP EDGES 0.010 INCH MAX.

,

3. SURFACE TREATMENT FINISH NO. 7.3.2 FOLLOW WITH SEMIGLOSS

PAINT SYSTEM NO. 21.5, COLOR OLIVE DRAB NO.X24087, MIL-STD-17.1

MU-E-312-34-4-20

Figure 4-20. Fuel tank clamp fabrication.

Section XI. GAS PLATE, COMPRESSOR NAMEPLATE,

PROTECTING CAGE, AND ENGINE MOUNTING FRAME

(3) Remove the backing from the new gas

4-59.

General

plate (27).

(4) Mount gas plate (27) by applying hand

General support maintenance personnel are authorized

pressure to the top of the plate.

to replace the gas plate, nameplate, mounts. and

attaching hardware.

4-61.

Compressor Nameplate

4-60.

Gas Plate (Fuel Tank)

a

Description.

The

aluminum-alloy

compressor nameplate identifies the unit.

The

a. Description. The fuel tank gas plate is

compressor nameplate is mounted to the bottom frame

made of aluminum foil and identifies the kind of fuel to be

by four rivets.

placed in the fuel tank. The plate is mounted by

pressure sensitive adhesive.

b.

Removal.

b.

Removal arid Installation

(1) Remove four rivets (32, fig. 3-2).

(1) Lift the edge of the gas plate (27, fig. 3-2)

(2) Remove nameplate (33).

with a sharp tool. Then, pull the plate completely off the

fuel tank (31).

c.

Installation.

(2) Clean the plate mounting surface with

(1) Position nameplate (33) to bottom

drycleaning solvent and air dry.

frame (38). Aline holes.

4-36