TM 5-4310-227-15

(30) from the keyway in the crank-

b. Cleaning, Inspection, and Repair.

Shaft.

(1) Clean all metal parts with an approv-

ed cleaning solvent and dry thorough-

Note. The helical gear is keyed on the

ly.

crankshaft. The gear should not be re-

moved unless inspection indicates that it

(2) Place rhe crankshaft cone and rollers

is damaged or worn and requires replacing

in a wire basket and lower the basket

(b (5) below).

into a container of approved cleaning

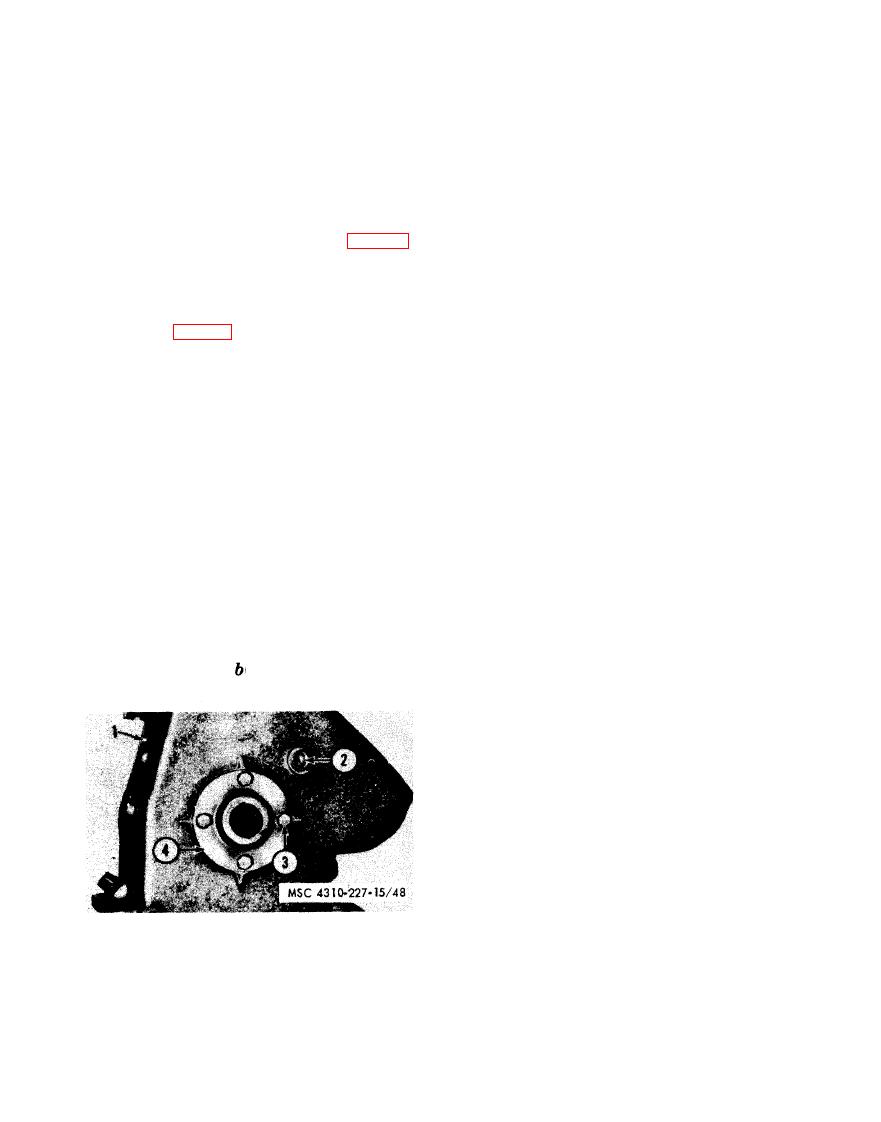

(8) Remove the four bolts (3, fig. 4-12)

solvent. Rotate the wire basket several

and lockwashers that secure the fly-

times until all oil sludge is loosened

wheel end plate (4) to the cylinder

and flushed out of the cones.

and crankcase assembly (1). Remove

(3) Remove the cone and rollers from the

the bearing plate and paper gasket

basket and allow to drain dry.

(4, fig. 4-11).

(4) After drying, inspect the cone and

rollers and roller bearing cups for

(9) Using a suitable puller, remove the

cracks, breaks, scoring, or signs of

roller bearing cup (7) from the fly-

wear. Replace a defective cone and

wheel end of the cylinder and crank-

rollers and roller bearing cup.

case assembly. In a similar manner, re-

Note. If the condition of a cone and

move the bearing cup from the drive

rollers or roller bearing cup is question-

pulley end plate (19).

able, replacement should be made im-

mediately.

(10) Use a blunt drift punch and hammer

(5) Inspect the crankshaft helical gear for

to remove the gasket (6) and oil seat

retainer (5) from the flywheel end

cracked, chipped, or broken teeth. Re-

plate (3) and the drive pulley end

place a worn or otherwise defective

plate (19) .

helical gear.

(6) I n s p e c t the crankshaft for nicks,

Caution: Since damage to the oil

burrs, cracks, scoring, and wear. Ex-

seal retainers is usually incurred dur-

amine t h e crankshaft journal for

ing removal, the retainers and the

r o u g h n e s s and wear. Measure the

gaskets shouId not be removed unless

l e n g t h , diameter, and taper of the

they are worn or damaged and are to

journal. Replace the crankshaft if the

be replaced ( (8) below).

journal length is more than 1.2550

inches; diameter is less than 1.125

inches; out-of-round or taper exceeds

0.0005 inch; or the radius of a jour-

nal shoulder fillet is less than 0.125

inch. If all measurements read favor-

ably, polish the journal with crocus

c l o t h and clean thoroughly. The

crankshaft should be metalized if in-

spection indicates the crankshaft jour-

nal wear exceeds the specified dimen-

sions as in (7) below. The crankshaft

alinement should be inspected before

and after any grinding operations. In-

spect the crankshaft for a runout in

1 Cylinder and crankcase assembly

excess of 0.007 inch. Replace a defec-

2 Expansion plug (2 rqr)

tive or worn crankshaft.

3 Bolt, machine, hex-hd, 5/18-18 X 3/4 in. (4 rqr)

(7) Metalizing and regrinding operations

4 Flywheel end plate

must be performed carefully and in

strict compliance with the grinding

4-31