(11) Clean the coils with a clean, dry cloth.

the defective windings must be re-

Caution: Coils should not be

placed.

cleaned by any degreasing method or

(14) Insulation on the coils that has worn

with any solvent, as this would dam-

away may be repaired by wrapping;

age the insulation and ruin the wind-

however, care must be exercised to

ings. Care should also be exercised

avoid excessive bulkiness. All soldered

in handling windings to avoid break-

connections should be made with resin

ing the connecting lead.

(12) Inspect the coils for worn or frayed

(15) Test the coils for a grounded circuit

insulation or defective connections

with the windings installed. Test be-

and repair as necessary.

tween a lead of the coils and the frame

assembly. If the lamp lights, a

( 1 3 ) Test the coils for an open circuit with

a test lamp circuit. Test across the

grounded condition exists and the de-

interconriections between coils. If the

fective windings must be repaired or

lamp fails to light, resolder the inter-

replaced.

connections, then test between the two

(16) Test the electrical receptacle connector

leads of the coils. Failure of the lamp

for shorts, open circuit, or a grounded

to light indicates an open circuit and

condition with a test lamp circuit. Test

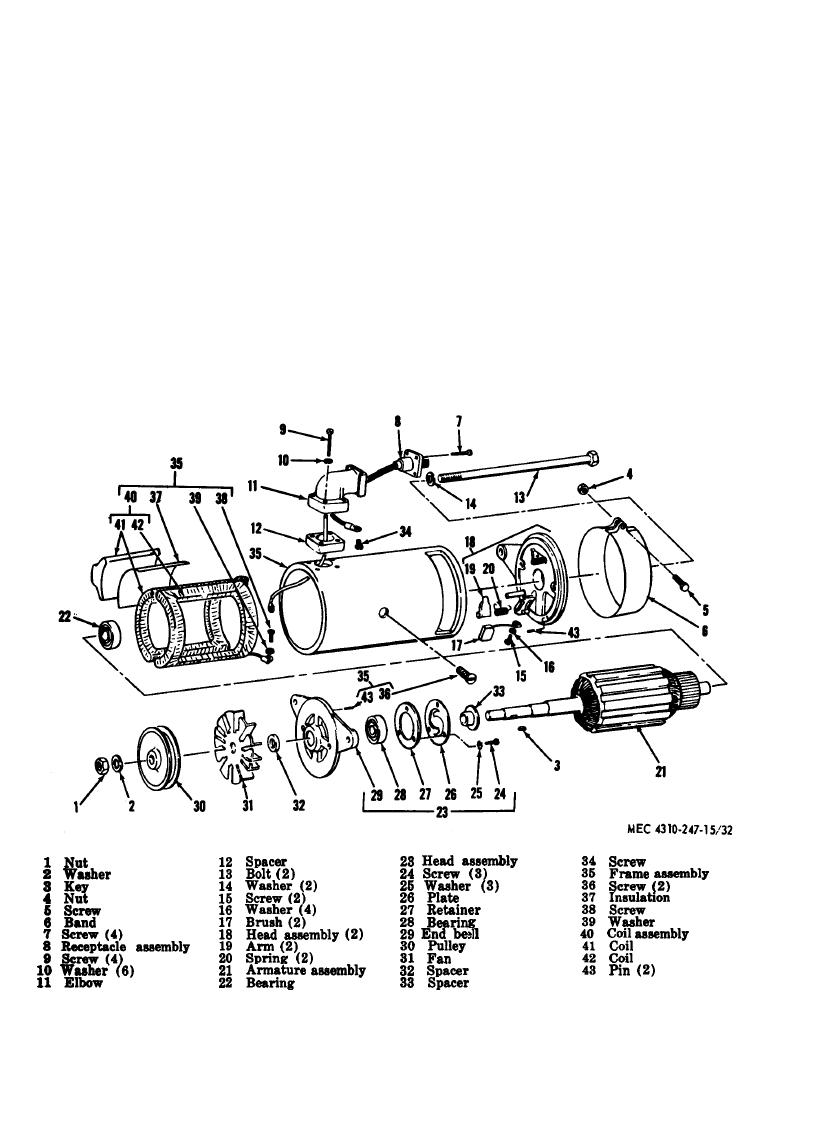

Figure 32.

Generator repair.

AGO 8166A

62