CHAPTER 6

COMPRESSOR REPAIR INSTRUCTIONS

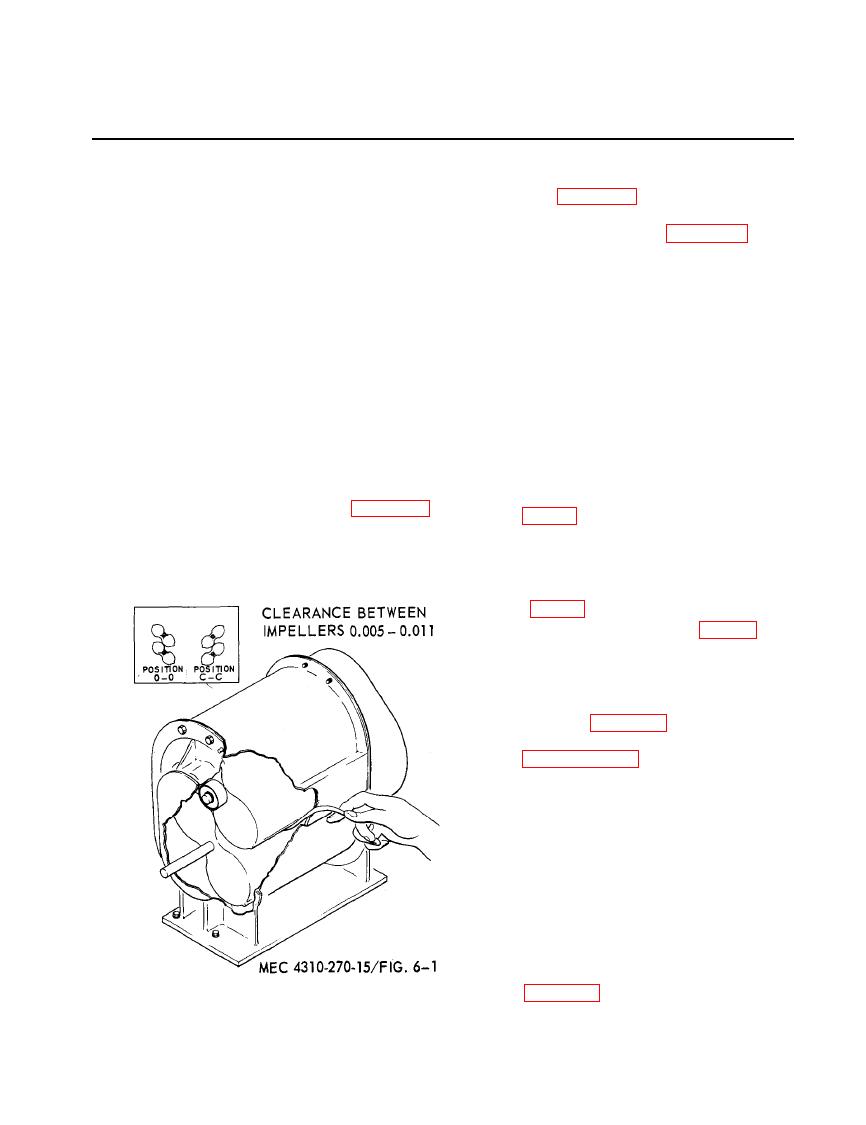

b. To Determine Total Clearance.

General

(1) Place the impellers in the 0-0 posi-

The air compressor has two figure eight im-

tion, figure 6-1.

pellers rotating in opposite directions. As each

(2) Measure the distance between 0-0

lobe of an impeller passes the blower inlet, it

with a feeler gauge, figure 6-1.

traps a quantity of air equal to exactly one-

(3) Rotate the impellers 90 degrees to

fourth the displacement of the compressor.

position c-c and measure distance be-

This entrapment occurs four times per revo-

tween c-c.

lution, moving the entrained air around the

(4) Add measurements 0-0 and c-c for

case to the blower outlet. Timing gears accu-

Desired clearance

total clearance.

rately position the impellers in relation to each

.005-.011.

other, maintaining the minute clearances so

c. To Determine Correct Clearance. Divide

vital to the high volumetric efficiency of the

the total clearance evenly between points 0-0

rotary positive blower.

and c-c.

Clearances

a. Impellers are held in time by taper pins

a. The clearances between impellers are

which secure the shaft and timing gears. To

measured at points 0-0 and c-c when the im-

re-time, it is necessary to remove only one ta-

pellers are in the position shown in figure 6-1.

per pin, (fig. 6-2).

The impellers are viewed from the drive end

(1) Insert a short length of pipe over the

of the blower; always face the drive shaft

shaft, clearing the taper pin, and

when determining clearances.

drive the timing gear further into the

shaft. This will loosen the taper pin,

(2) Remove the taper pin, (fig. 6-4).

(3) With a gear puller, pull the gear

away from the blower so that the

front face of the gear is 1/16 of an

inch past the front face of the mat-

ing gear, figure 6-5.

(4) Determine the correct clearance,

(5) Insert shim stock of proper thickness

between the impellers (because the

unit is out of time, it will probably be

necessary to wedge the shim stock

into position by rotating the impel-

lers).

(6) Place a short length against the un-

pinned gear and strike the pipe a

quick blow. This will drive the gear

further into the shaft, causing it to

turn relative to the shaft because of

the torque set up by the shim stock,