TM 5-4310-275-14

7.

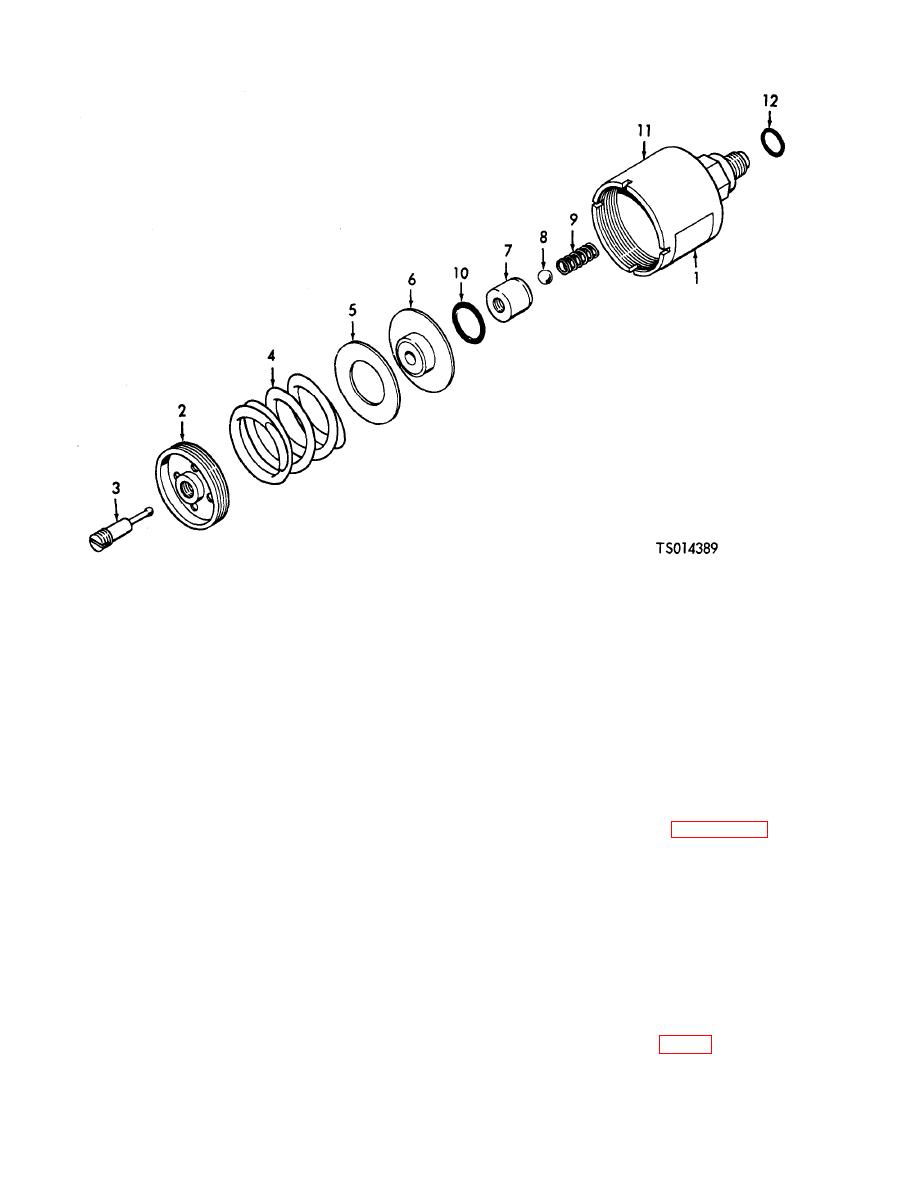

Piston assembly

1. Identification plate

8.

Ball

2. Adjusting screw

9.

Spring

3. Stem

10.

Preformed packing

4. Spring

11.

Body

5. Spring shim

12.

Gasket

6. Spring retainer

adjusting screw and metal ball for scoring,

WARNING

scratches, nicks and signs of wear.

Dry cleaning solvent, Fed. Spec. P-D-680

(4) Do not attempt to repair damaged or

or P.S-661, used to clean parts is

questionable parts. Discard all such items and

potentially dangerous to personnel and

install new parts during reassembly.

property. Avoid repeated and prolonged

e. Reassembly. Refer to Figure 6-1 and

skin contact. Do not use near open flame

assemble the pressure relief valve.

or excessive heat. Flash point of solvent

(1) Apply a thin film of pneumatic system

is 100 F. (38 C.) --138 F. (59 C.).

grease (Specification MIL-G-4343) to new O-ring

d. Cleaning and Inspection.

packing (10), packing groove in body (11), and

(1) Wash all parts with dry cleaning solvent,

mating surfaces of body and piston assembly (7).

Fed. Spec. P-D-680, and dry -thoroughly with

(2) Insert O-ring packing (10) in groove in

clean, lint-free cloths. Use filtered, compressed

bore of body (11). Install ball return spring (9)

air to blow solvent. and residue from all crevices,

and metal ball (8) in bore of body.

springs, and air passages.

(3) Install piston assembly (7) in body (11)

(2) Inspect parts for damaged screw threads,

and down over metal ball (8) and spring (9).

cracks, breaks, or worn areas in anodized sur-

(4) Insert spring retainer (6), cupped side

faces, and other obvious indications of wear,

against piston assembly (7, fig. 6-1 ).

damage and deterioration,

(5) Place shims (5) and spring (4) in body

(3) Inspect finished surfaces of body, stem,