TM 5-4310-275-14

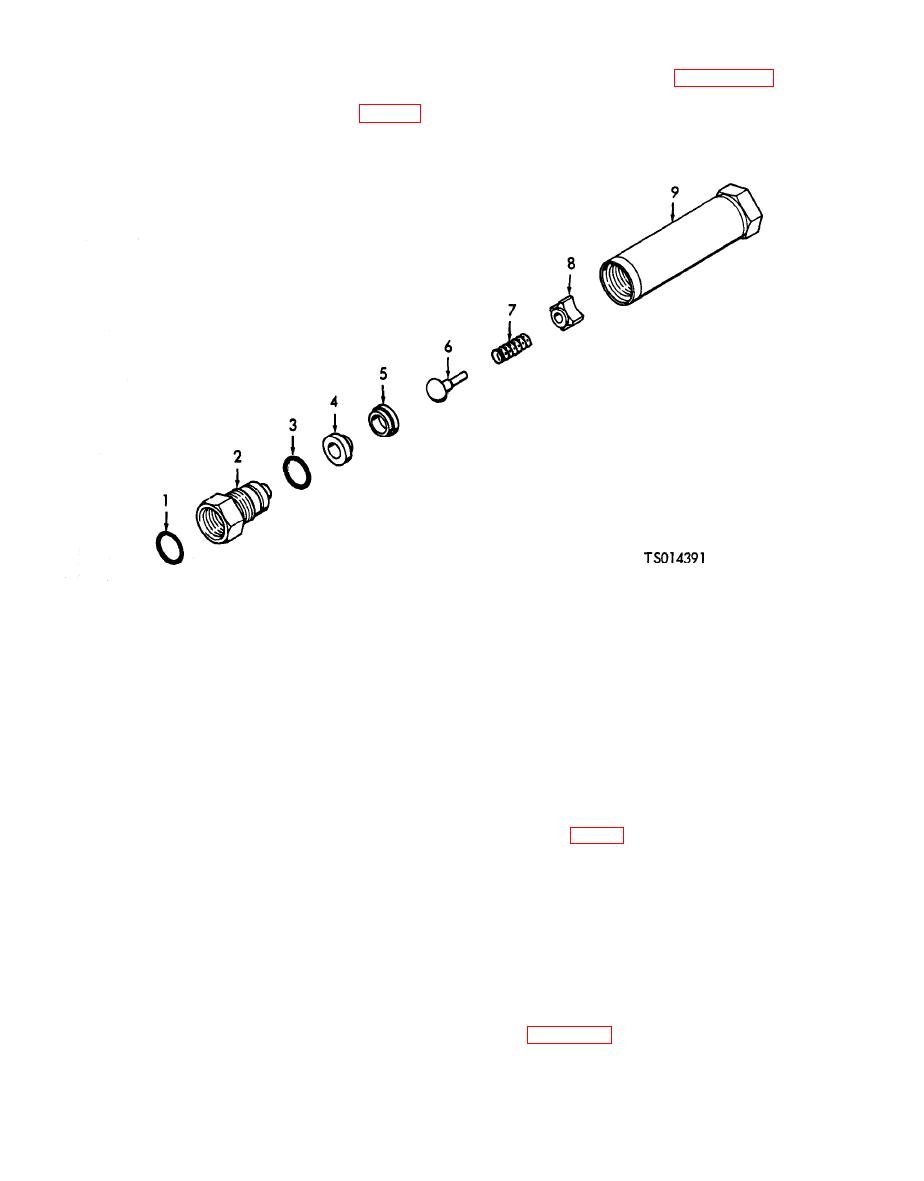

c. Disassembly. Refer to Figure 6-3 and

pneumatic system to prevent reverse air flow

disassemble the check valve in the sequence of the

from the pressure tank.

index numbers.

31).

6. Poppet

1. Gasket

7. Spring

2. Body screw

8. Poppet guide

3. Preformed packing

9. Valve body

4. Valve seat

5. Seat retainer

of spring should be 0.396 0.005 inch (1.0058

WARNING

.0127 cm).

Dry cleaning solvent, Fed. Spec. P-D-680

( 4 ) Discard all damaged, worn and

or P-S-661, used to clean parts is

questionable parts.

potentially dangerous to personnel and

e. Reassembly.

property. Avoid repeated and prolonged

(1) Apply a thin film of pneumatic system

skin contact. Do not use near open flame

grease, Specification MIL-G-4343, to threads of

or excessive heat. Flash point of solvent

body screw (2, fig. 6-3).

is 100 F. (38 C.) --138 F. (59 C.).

(2) Install poppet guide (8), spring (7),

d. Cleaning and Inspection.

(1) Wash all parts in dry cleaning solvent,

poppet (6), seat retainer (5) and valve seat (4) in

Fed. Spec. P-D-680. Do not soak parts. Dry

valve body (9).

thoroughly with clean, filtered, compressed air or

(3) Position O-ring packing (3) in groove of

body screw (2). Screw body screw into valve body

(2) Inspect parts for evidence of damage and

(9) and tighten with a torque of 600 25 pound-

wear such as stripped screw threads, scratches

inches (6.9702 .2904 kgm).

and scoring of finished surfaces, nicks and burrs

f. Test. Test the reassembled check valve as

on valve surfaces.

follows:

(3) Check poppet return spring for defor-

(1) Install the check valve in a test setup as

mation and damage. Spring must be cylindrical

shown in Figure 6-4.

in shape with ends closed and square. Free length