TM 5-4310-275-14

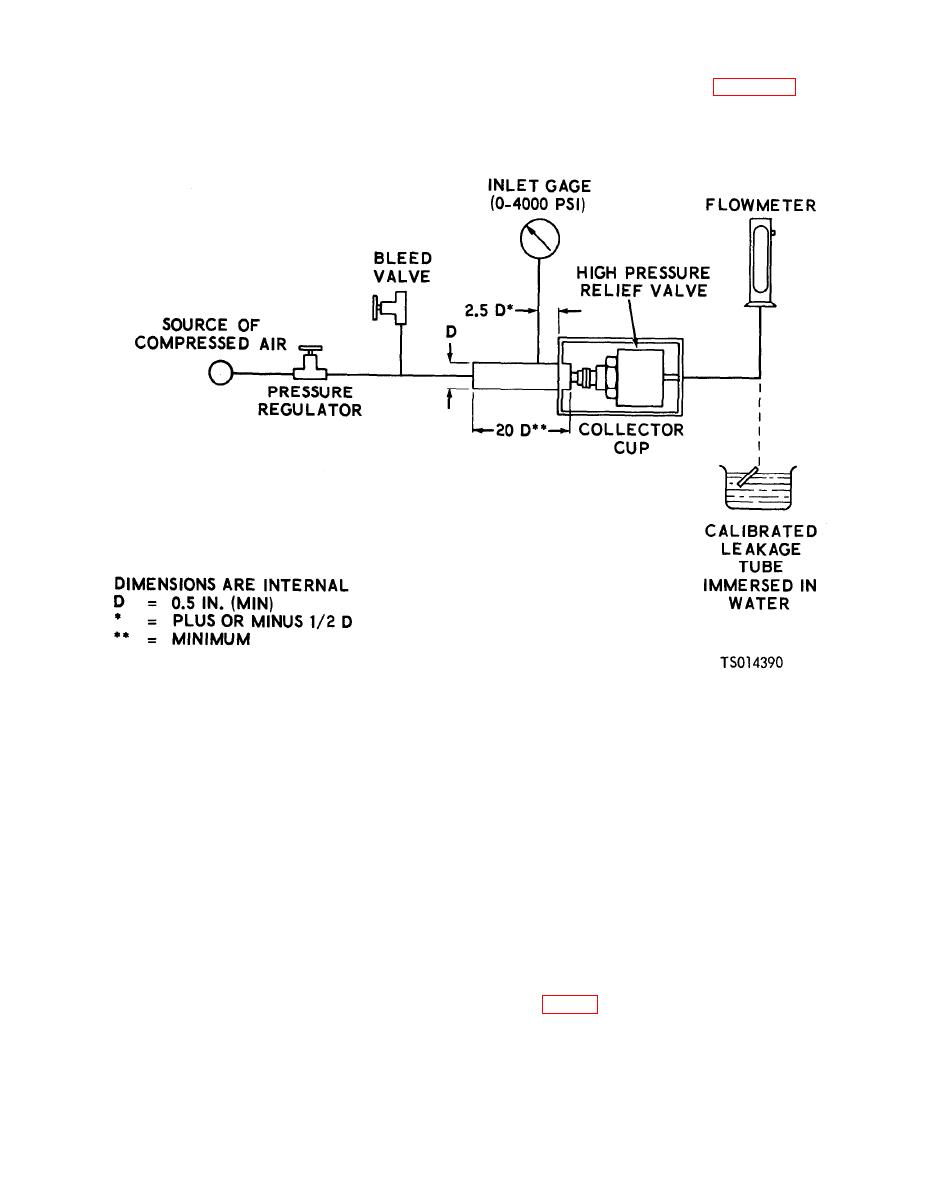

(11). Screw adjusting screw (2) into body. Screw

to observe dimensions specified for approach and

stem (3) into adjusting screw.

f. Test and Adjustment.

exit sections.

(1) Install pressure relief valve in test setup

(5) If required relief valve operation cannot

(2) Close bleed valve. Adjust pressure

be obtained by adjusting stem, change setting of

regulator to apply a gradually increasing air

adjusting screw installed in valve body, and

pressure to approach section. Relief valve should

repeat complete test and adjustment procedure.

open (i.e., air flow from leakage tube exceed three

Final setting of adjusting screw and stern must

cubic centimeters per hour) before applied

allow installation of 0.025 inch (.0635 cm)

pressure reaches 3600 psig (253.08 kg per sq cm).

diameter stainless steel safety wire and lead seal

(3) If relief valve fails to open, remove

as in original valve configuration.

collector cup, adjust stem of valve a small

amount, replace collector cup, and repeat test.

(6) Close pressure regulator, open bleed

Repeat alternate adjustments and tests until

valve to relieve air pressure in test setup and

relief valve opens, as indicated by a minimum air

disconnect pressure relief valve from test

flow of 0.6 scfm, with an approach section

equipment.

pressure of 3300 to 3500 psig (231 .990 to 246.05

g. Installation.

kg per sq cm) maximum.

(1) Install a new tube fitting gasket into the

(4) Close pressure regulator and open bleed

groove at the root of the valve body mounting

valve slightly to slowly relieve air pressure in

boss (fig. 6-1).

approach section. Pressure relief valve should

(2) Install the pressure relief valve.

close (reseal) before approach section pressure

drops below 3100 psi (217.9300 kg per sq cm) as

a. General. The check valve is installed in the

indicated by pressure gage.