TM 5-4310-276-14

Table 3-2. Troubleshooting (Cont`d)

Malfunction

Test or Inspection

Corrective Action

c. Lift out air cleaner element (4) and check for dirt. Service the air cleaner.

WARNING

Dry cleaning solvent, P-D-680, used to clean parts is potentially dangerous to

personnel and property. Avoid repeated and prolonged skin contact. Do not

use near open flame or excessive heat. Flash point of solvent is 100F. (38C.).

(1) Clean the air cleaner with cleaning solvent, item 5, App. D, and dry thoroughly,

(2) Clean filter element by blowing out with air or washing with cleaning solvent, item 5, App. D.

(3) Inspect the air cleaner for cracks, dents, breaks, and other damage.

(4) Replace defective filter element or the complete cleaner assembly as required.

(5) Position air cleaner element (4) in base (5).

(6) Position cover (3) on base and install attaching screws (1) and lockwashers (2).

Step 2. Check for leaks from air receiver tank fittings with soapy water.

Secure fittings as necessary.

2. EXCESSIVE COMPRESSOR OIL CONSUMPTION.

Replace compressor crankcase oil.

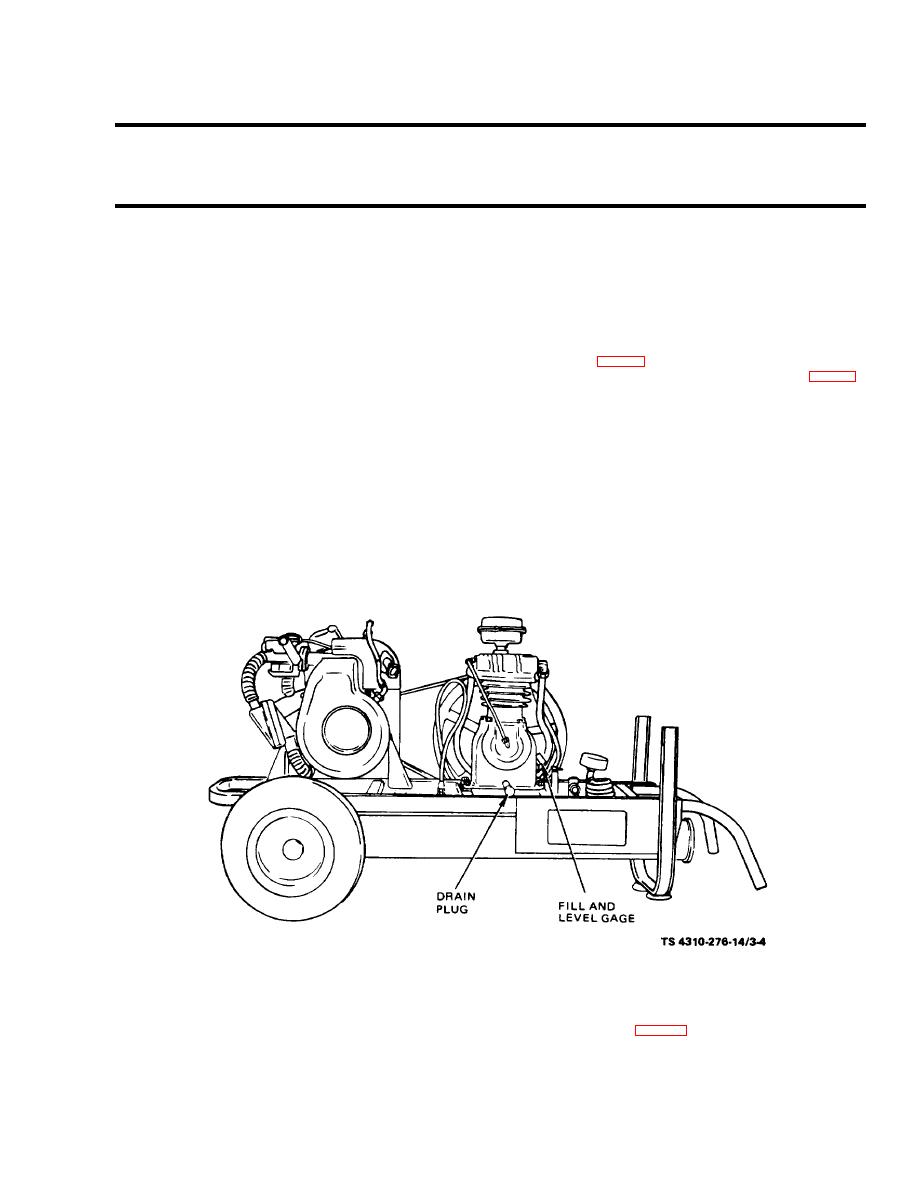

a. Position suitable container beneath compressor crankcase drain plug and remove drain plug (figure

3-4).

b. Install drain plug when oil is completely drained.

c. Remove combined oil filler plug and bayonet type level gage (fig. 3-4).

d. Fill crankcase with 1 quart (0.94 liters) of correct type of oil as follows:

3-11