TM 5-4310-276-14

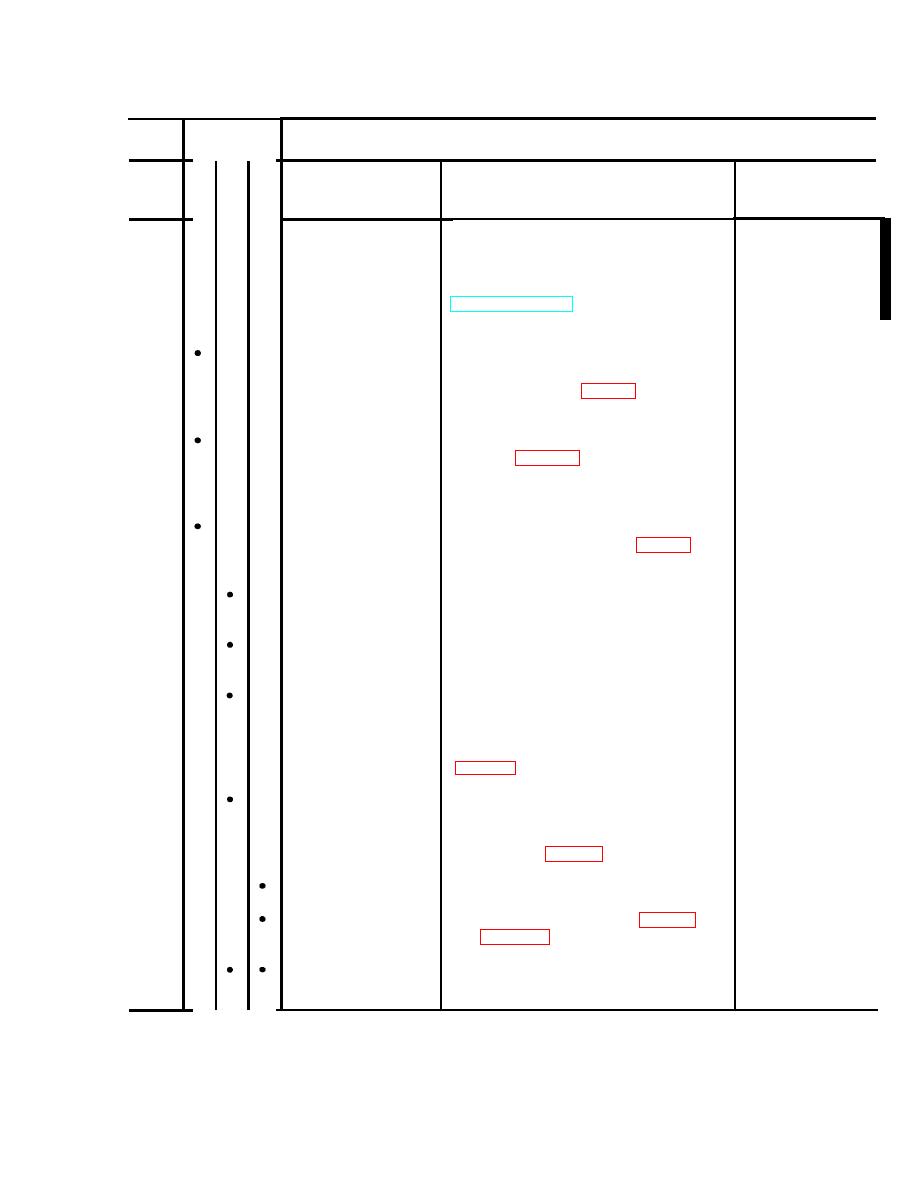

Table 3-1. OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

AAFTER OPERATION

BBEFORE OPERATION

DDURING OPERATION

INTERVAL

PROCEDURES

EQUIPMENT IS

NOT READY/

ITEM

ITEM TO BE

CHECK FOR AND HAVE REPAIRED

AVAILABLE IF

B

D

A

NO.

INSPECTED

OR ADJUSTED AS NECESSARY

NOTE

Perform lubrication prior to or

in conjunction with before PMCS.

For compressor lubrication refer to

LO 5-4310-276-12. For engine lubrica-

tion refer to LO 5-2805-256-12.

A leak or

1

Walk around unit and visually inspect

Complete unit

damage is found

for fuel and oil leaks, loose connec-

which would im-

tions, and damage (fig. 1-1 and 1-2).

pair operation.

Fire extinguisher

a. Fire

Check availability of and for proper

is missing

pressure (para 2-6).

Extinguisher

or pressure is

too low.

Check engine and compressor oil

b. Oil levels

levels. Add oil as required (fig. 3-1

and 3-2).

Check for proper operation and for

2

Controls and

Instruments

specified limits.

175 psi cannot

Normal operating pressure 140 to

a. Air pressure

175 psi.

be obtained.

gage

Check restriction indicator. If in-

b. Engine air

dicator is red or indicating service

cleaner restriction

indicator

or engine runs erratically or misses,

notify Organizational Maintenance

When compressor pumps slowly

c. Compressor air

cleaner

or does not provide sufficient air

pressure, notify Organizational

Maintenance (fig. 3-3).

Fill tank at completion of operation.

Fuel Thank

3

Air Receiver Tank

Drain water from the tank (fig. 3-6

4

and para 3-12).

Belts are cracked

Check for cracked or dry rotted belts.

Drive Belts

5

or broken.