TM 5-4310-276-14

(6) Inspec the key for chips, burrs and snug

fit.

(7) Replace any defective parts.

(8) Inspect the V-belt guard and mounting

brackets for dents, cracks or other damage.

Straighten minor dents and bends in the guard and

brackets.

(9) Inspect all attaching hardware for dam-

aged threads. Replace damaged attaching hardware

and replace an unserviceable guard, bracket or

other defective part.

(10) Blow out all grease and dirt collected in-

side the tubes.

(11) Inspect the tubes for dents, holes and

cracks. Replace a defective tube.

c. Installation.

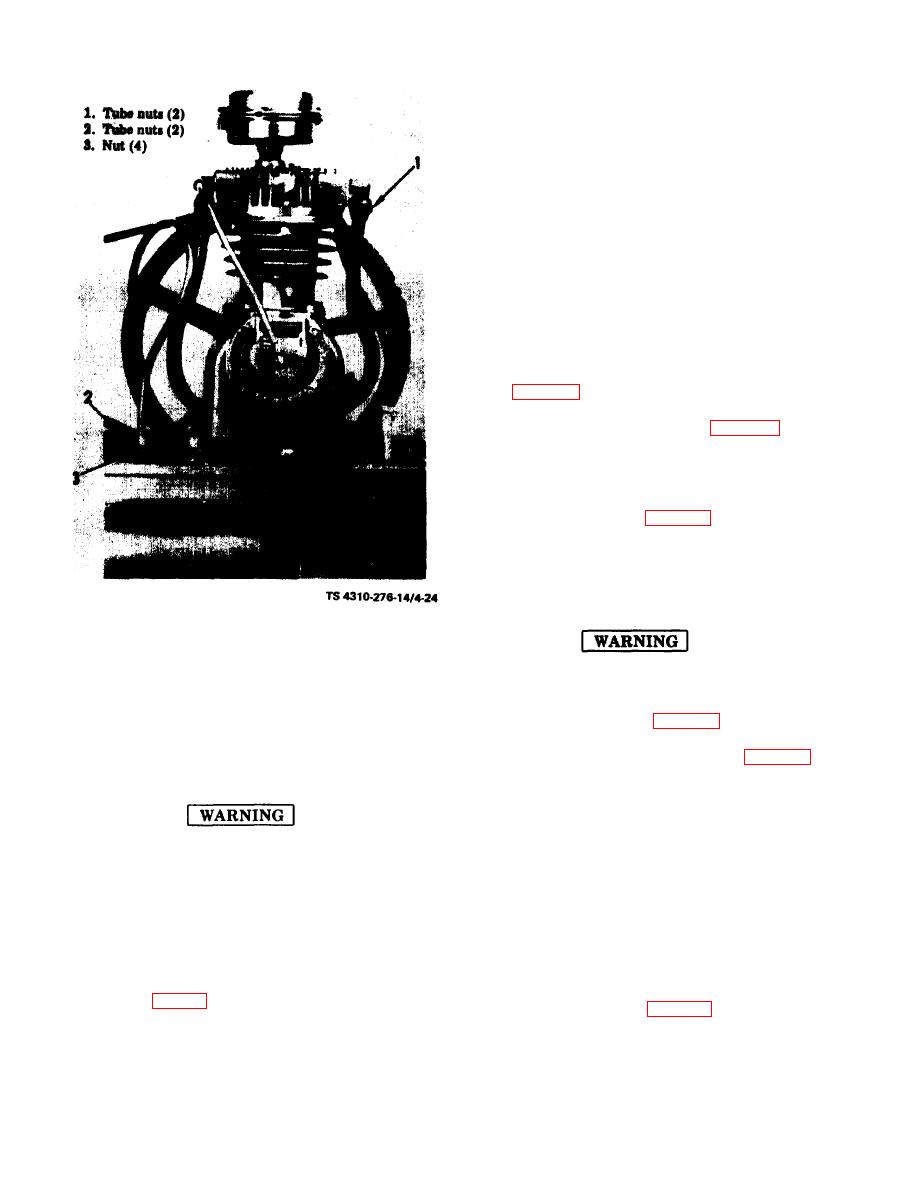

(1) Place compressor on handtruck and install

nuts (3, fig. 4-24). Attach aftercooler tube nuts (2)

and intercooler tube nuts (1).

(2) Install flywheel pulley, (4, fig. 4-23) and

key (5). Tighten nut (3) to 43 footpounds.

(3) Install V-belts (2) and adjust tension to

obtain belt deflection of 3/4 to 1 inch midway be-

tween pulleys. Tighten engine mounting bolts (1).

(4) Attach belt guard (fig. 4-16) with nuts and

capscrew.

(5) Service compressor crankcase.

4-32. Belt Guard.

a. Removal.

moval and installation.

Do not operate the air compressor

(6) Remove nuts (3) and lift compressor from

with the belt guard removed.

base.

b. Cleaning and Inspection.

(1) Clean the V-belts with a clean dry cloth,

(1) Remove belt guard (fig. 4-16) by removing

taking care to remove all dirt, grease and oil.

capscrew and nuts.

(2) Inspect the V-belts for cuts, fraying and

(2) Loosen engine mounting bolts (1, fig. 4-23)

wear.

to relaease tension on V-belts. Remove V-belts (2).

(3) Replace worn or damaged V-belts.

b. Cleaning and Inspection.

(1) Clean the V-belts with a clean dry cloth,

taking care to remove all dirt, grease and oil.

Drycleaning solvent, P-D-680, used to

(2) Inspec the V-belts for cuts, fraying and

clean parts is potentially dangerous to

wear.

personnel and property. Avoid re-

(3) Replace worn or damaged V-belts.

peated and prolonged skin contact.

NOTE

Always replace the V-belts in matched set of two.

Do not use near open flame or exces-

sive heat. Flash point of solvent is

c. Installation and Adjustment.

100F (38C).

(1) Install V-belts and adjust tension to ob-

tain belt deflection of 3/4 to 1 inch midway between

(4) Clean all other parts with cleaning sol-

pulleys. Tighten engine mounting bolts.

vent, item 5, App. D.

(2) Attach belt guard (fig. 4-16) with nuts and

(5) Inspect the flywheel pulley for chips and

capscrews.

cracks.