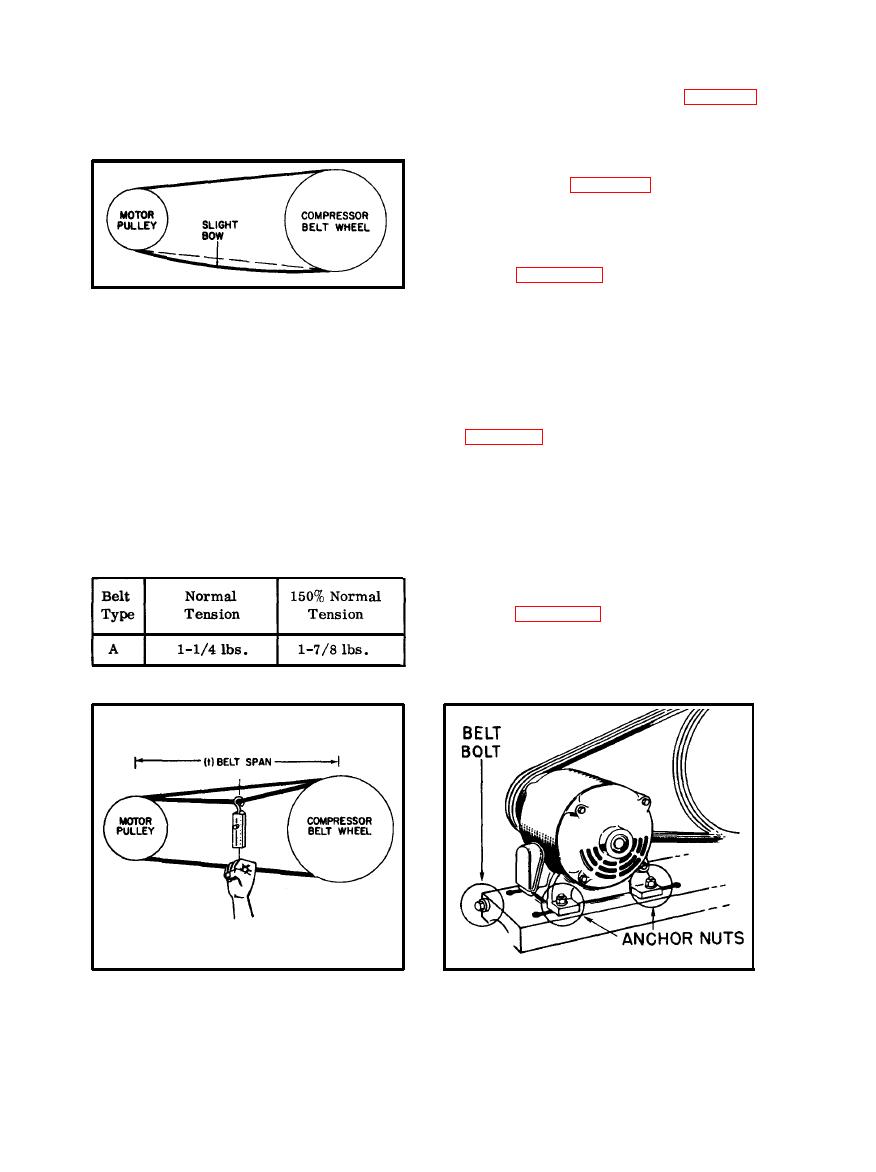

5 - 5 . 1 . If a slight bow in the belts is evi-

dent as shown in Figure 5-1, the belts are

usually adjusted satisfactorily. However,

a more accurate method of checking belt

tension is by the spring scale measurement

that follows. Measure the belt span (t) as

shown in Figure 5-2. At the center of the

span (t) apply a force perpendicular to the

span by attaching a spring scale to the two

outside belts. The force applied to the

spring scale should be sufficient to deflect

ing Belt Tension

the belts 1/64" for every inch of span length

(t). For example: The deflection of a 100"

span would be 100/64" or 1-9/16", thus, the force applied to the spring scale should deflect

the belts to 1-9/16". When the belts are deflected the necessary distance, compare the spring

scale reading (in lbs. force) with the values given in Table 5-4. If the reading is between the

value for normal tension and 150% normal tension, the belt tension should be satisfactory. A

reading below the value for normal tension indicates the belt slack should be reduced, and,

conversely, a reading exceeding the value for 150% normal tension indicates the belt slack

should be increased. Experience has shown that a new drive belt can be tightened initially to

two times normal tension to allow for any drop in tension during run in.

TABLE 5-4. BELT TENSION

5-5.2. When installing new belts, do not

pry the belts over the pulley grooves. Loos -

en the anchor nuts and the belt tightener

shown in Figure 5-3 and push the motor

toward the compressor. After the belts are

over the pulleys, use the belt tightener to

adjust the belt tension.

Checking Belt Tension

5-3