SEPARATING THE PISTON FROM THE ROD. To separate the piston from the con-

5-8.

netting rod, proceed as follows:

5-8.1. Remove the air head cap screws (Figure 5-4) and pull the air head off the cylinder.

If the gasket sticks, remove it with a thin blade.

5-8.2. Disconnect any assemblies or piping that may prevent removing the cylinder. Now,

take out the cap screws securing the cylinder to the frame and pull the cylinder over the

piston.

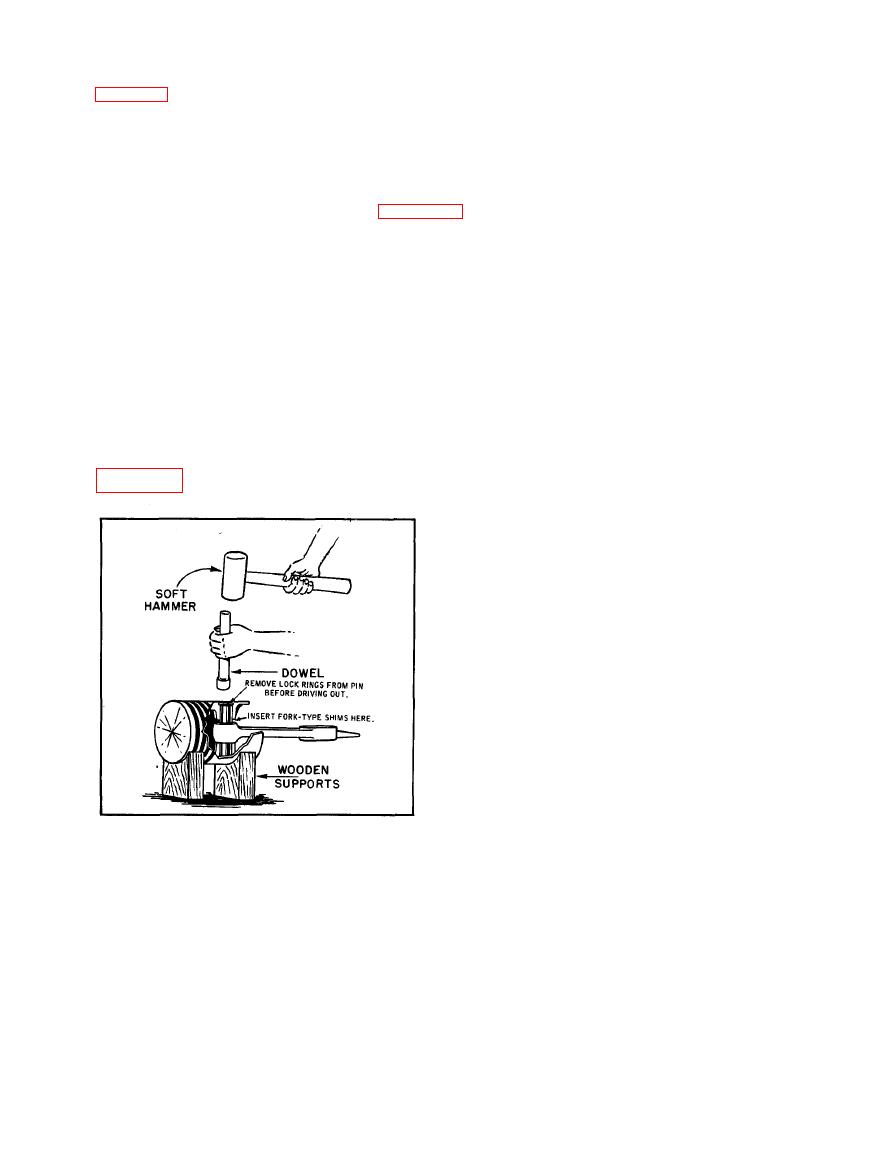

5-8.3. To avoid bending the connecting rod when driving out the piston pin, we recommend

removing the piston and rod assembly from the crankshaft. To do this, drain the oil from

the frame and remove the frame end cover. Then, take the centrifugal unloader assembly off

the end of the crankshaft and pull the connecting rod off its throw.

5-8.4. Remove the piston pin lock rings from their grooves and with a dowel of appropriate

size and a soft hammer, drive out the piston pin. Important: To prevent piston distortion

during this operation, play between the piston pin bosses and connecting rod must be elimi-

nated by inserting fork-type shims of the necessary thickness between the rod and boss. See

ASSEMBLY RE-

CRANKSHAFT

PLACEMENT. A new crankshaft assembly

includes bearings, spacer etc. , all of which

are installed as a unit. To remove the old

crankshaft and install a new one, refer to

Figure 6-2 and proceed as follows:

5-9.1. First remove the fan-type flywheel,

f l y w h e e l key and shaft end cover. Next,

d r a i n the crankcase oil, then remove the

c r a n k c a s e end cover and centrifugal un-

l o a d e r assembly.

5 - 9 . 2 . Remove the cylinder to crankcase

cap screws and pull the cylinders over the

pistons. Remove the centrifugal unloader

a n d connecting rods from the end of the

crankshaft, and take the snap ring from the

outer bearing. It may be necessary to drive

t h e c r a n k s h a f t e n d w i s e b e f o r e removing

Figure 5-8. Recommended Method of

snap ring.

Removing or Replacing Piston Pin

5-9.3. The crankshaft assembly is a moderate press fit in the crankcase and may be forced

out by tapping the flywheel end of the shaft with a lead hammer.

5-9.4. Prepare the new crankshaft assembly for installation by removing the snap ring from

the outer bearing, grasping it near the end and springing it from the groove.