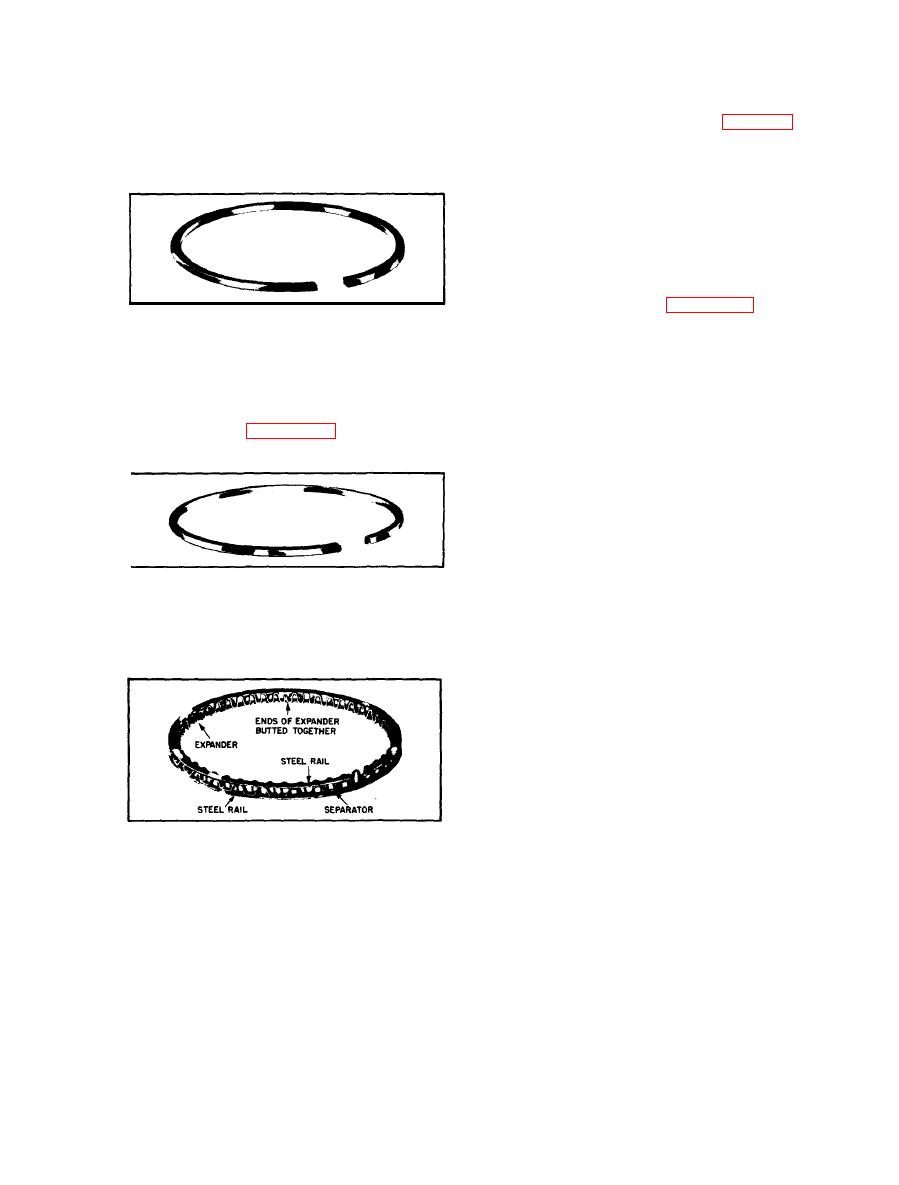

5-7.4. Oil rings are classed as "H" type,

is a single-piece, non-ventilated, beveled-

scraper style ring. This style ring has both

beveled and undercut edges which allow it to

act as a combination oil-scraper and com-

pression sealing ring. See Figure 5-6. The

"M" type ring is a four-piece, ventilated,

chrome plated, steel rail style ring. This

Taper-Faced Style Compression Ring

style ring utilizes an expander which exerts

a uniform pressure all the way around two

independent, thin, cylinder contacting rails, the rails being held apart by an open separator.

This style of ring provides maximum oil drainage with the most uniform and positive con-

formability. See Figure 5-7.

5-7.5. The following paragraphs contain

complete instructions, in step-by-step pro-

cedure, for the disassembly, cleaning, in-

spection and replacement of cylinders, pis -

ton rings and pistons; therefore, before

installing new replacement piston rings, we

recommend that the entire procedure be

very carefully read. Refer to Figure 6-2.

Non-Ventilated Beveled-Scraper Style

5-7.5.1. Disconnect any tube lines to the

Oil Control Wiper Ring

air head. Remove the air head attaching

screws and washers and then remove the

entire air head assembly from the cylinder.

Remove the air head gasket. If the gasket

sticks, a thin blade may be used to pry the

gasket loose from the air head or the cyl-

inder.

5-7.5.2. Remove the cylinder attaching

screws and washers and then carefully re-

move the cylinder from over the piston

and piston rings. Remove the cylinder-to-

crankcase gaskets.

Ventilated, Chrome Plated Steel Rail

Style Oil Control Wiper Ring

5-7.5.3. Remove the piston from its con-

necting rod and then remove all of the old piston rings from the piston.

5-7.5.4. Thoroughly clean the air head by brushing or scraping lightly to remove any accu-

mulated carbon deposits. Make sure the gasket surface is thoroughly cleaned of any gasket

particles.

5-5