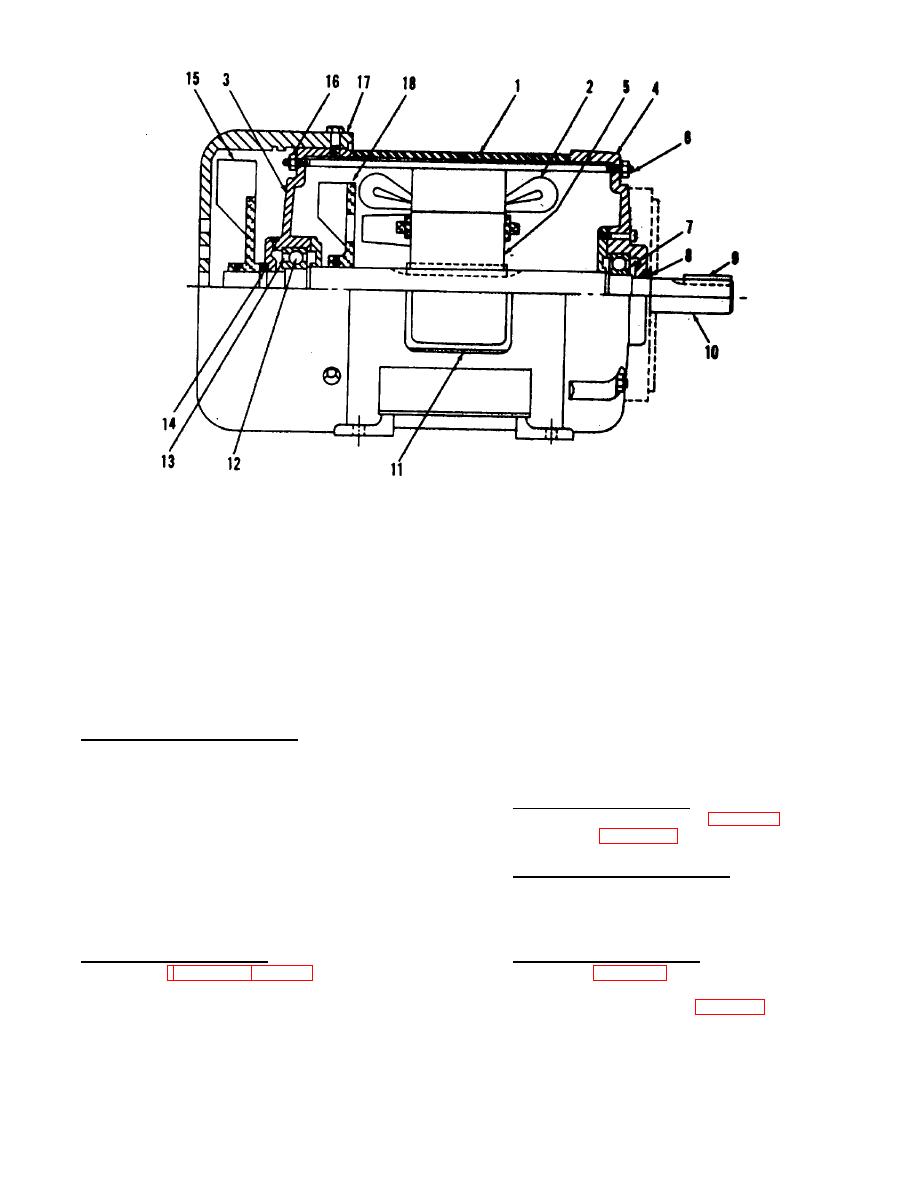

1.

Body assembly

10.

Shaft L

2.

Stator wedge kit

11.

Conduit box assembly

3.

Bracket, front

12.

Bearing

4.

Bracket, rear

13.

Spring, loading

5.

Rotor assembly

14.

Flinger, external

6.

Bolt, stud

15.

Fan, external

7.

Bearing

16.

Nut

8.

Flinger, external

17.

Cover, fan

9.

Key

18.

Fan

Figure 19. Electric motor assembly.

2. Cleaning, Inspection, and Repair.

2. Press bearing cup in the unloader housing.

a. Clean all parts in an approved cleaning solvent

3. Install new gasket on the unloader homing.

and dry thoroughly.

b. Inspect the crankshaft for cracks, scores, and

C. ELECTRIC MOTOR

distortion Measure the crankshaft journals for

1. Removal and Disassembly.

a. Remove the electric motor, Section VIII, B1.

wear. If the connecting rod journals measure

b. Refer to figure 19 and disassemble electric

0.0005

inch

out-of-round,

replace

the.

motor.

crankshaft.

2. Cleaning, Inspection, and Repair.

c. Inspect the crankshaft bearings for rough, pitted,

a. Clean all parts with an approved cleaning solvent

or scored rollers. Replace a defective hearing.

and dry thoroughly.

d. Inspect the crankcase for cracks, breaks or

b. Inspect all parts for wear or damage and replace

other defects.

Replace the crankcase if

worn defective part

defective.

3. Reassembly and Installation.

3. Reassembly and Installation.,

a. Refer to figures 17 and 18 reassemble and

a. Refer to figure 19 and reassemble the electric

install cry shaft in crankcase using the following

motor.

procedures:

b. Install the electric motor, Section VIII, B2.

1.

Always install new oil seal in crankcase.

20