TM 5-4310-352-14

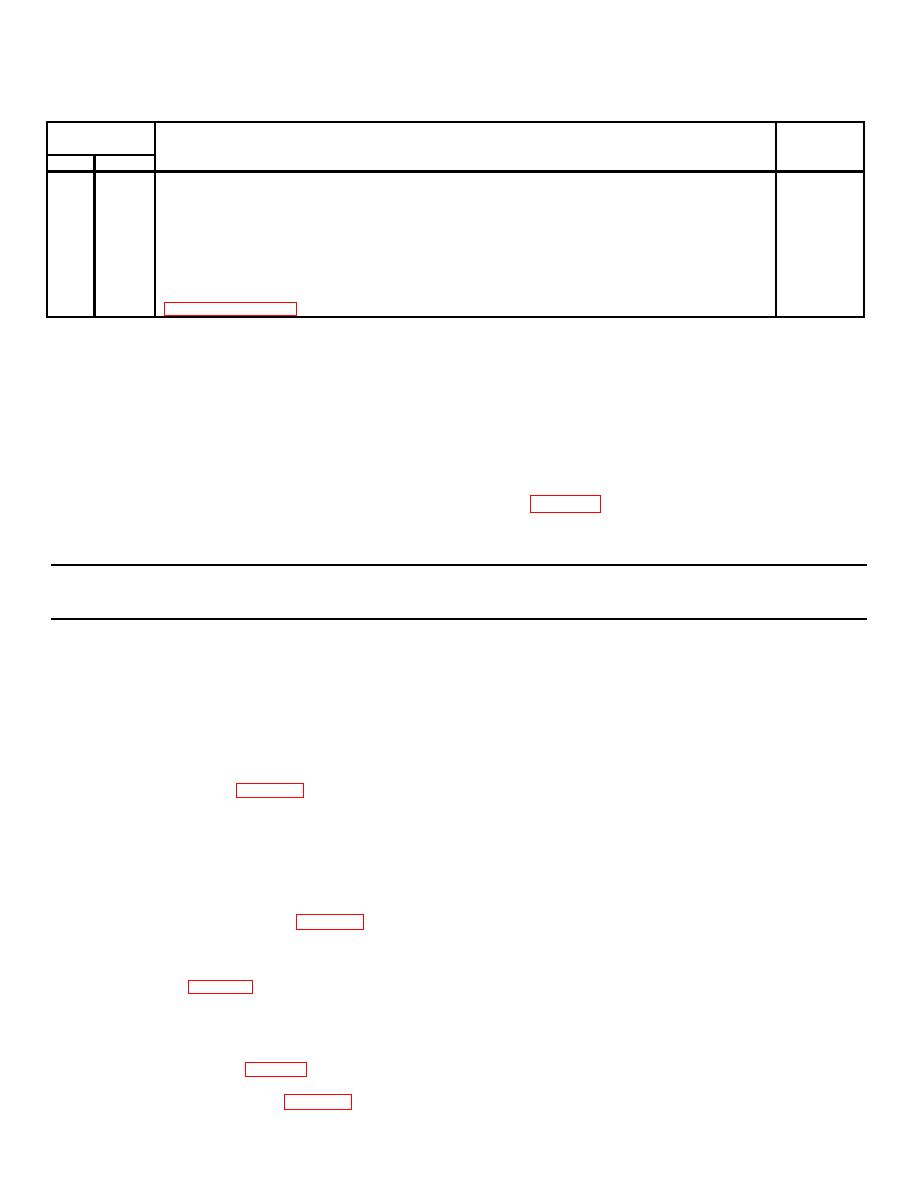

Table 3-2. Operator/Crew Preventive Maintenance Checks and Service Continued

D-Daily

W-Weekly

Time required: 0.2

Time required: 0.4

Interval and

Sequence No

Item to be inspected

Work time

D

W

procedure

(M/H)

0.1

2

SWITCHES AND CONTROLS

Check for loose wires on switches, motor starter, or motor. Notify organizational maintenance of

defect.

3

DRIVE BELTS

Check for wear and proper tension of drive belts. Adjust belts by moving motor away from com-

0.1

pressor and tighten mounting nuts.

4

SAFETY RELIEF VALVES

Check for proper operation, by lifting lever

0.1

Section III. TROUBLESHOOTING

b. This manual cannot list all malfunctions that

3-5. General

may occur, nor all tests or inspections and corrective ac-

a. This section contains troubleshooting informa-

tions. If a malfunction is not listed or is not corrected by

tion for locating and correcting most of the trouble that

listed corrective action, you should notify higher level

may develop in the air compressor. Each malfunction for

maintenance.

an individual component is followed by a list of test or

inspections which will help you to determine probable

causes and corrective actions to take. You should perform

3-6. Troubleshooting

the test inspections and corrective actions in the order

Refer to Table 3-3 below for malfunctions, test or inspec-

listed.

tion, and corrective actions.

Table 3-3. Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOTE

Before you use this Table, be sure you have performed all applicable operating checks. If you have a malfunction which is not listed

in this table, notify the next higher level of maintenance.

1. COMPRESSOR PUMPING OIL

Step 1.

Check for a clogged inlet filter.

(1) Clean body of filter, inspect pads for excessive wear or loss of capacity to retain dust and dirt.

(2) Replace defective pads.

Step 2.

Check oil level (LO 5-4310352-12).

Add oil if necessary.

Step 3.

Check for leaking or maladjusted pilot valve.

Adjust pilot valve (para 3-12).

2. KNOCKS OR RATTLES

Step 1.

Check for loose belt pulley, or motor with excessive end play in shaft.

Notify organizational maintenance.

Step 2.

Check for leaking valves, or restricted air passage.

Notify direct support maintenance .

3. AIR DELIVERY DROPPING

Step 1.

Check for clogged inlet filter.

Service the inlet filter (para 3-13).

Step 2.

Check for air leaks in piping.

Make a solution of soapy water and apply at fittings. If leak is found, notify organizational ,Maintenance.

Step 3.

Check for leaking or maladjusted pilot valve.

Adjust the pilot valve (para 3-12). If leaking, notify organizational maintenance.

4. MOTOR OVERLOAD RELAY TRIPS

Step 1.

Check lubricating oil used.

Use proper oil as specified in lubrication order.

Step 2.

Check V-belts for too tight adjustment.

Adjust V-belts (para 3-8).

Step 3. Check for leaking or maladjusted pilot valve.

Adjust the pilot valve (para 3-12). If leaking notify organizational maintenance.

3-5