TM 5-4310-352-14

CHAPTER 5

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS SPECIAL TOOLS AND EQUIPMENT

5-1. Special Tools and Equipment

5-2. Maintenance Repair Parts Repair parts and equip-

There are no special tools, or equipment, required for

ment covering direct and general support maintenance of

maintenance of the air compressor assembly.

the air compressor assembly are listed and illustrated in

TM 5-4310-352-24P.

Section II. TROUBLESHOOTING

may occur, not all tests or inspections and corrective ac-

5-3. General

tions. If a malfunction is not listed or is not corrected by

a. This section contains troubleshooting informa-

the listed corrective action, notify your Supervisor.

tion for locating and correcting most of the trouble that

may develop in the air compressor. Each malfunction for

an individual component is followed by a list of tests or

5-4. Troubleshooting

inspections which will help you determine probable

causes and suggested corrective actions to remedy the

find during the operation or maintenance of the air com-

malfunction.

pressor or its components. You should perform

b. This manual cannot list all malfunctions that

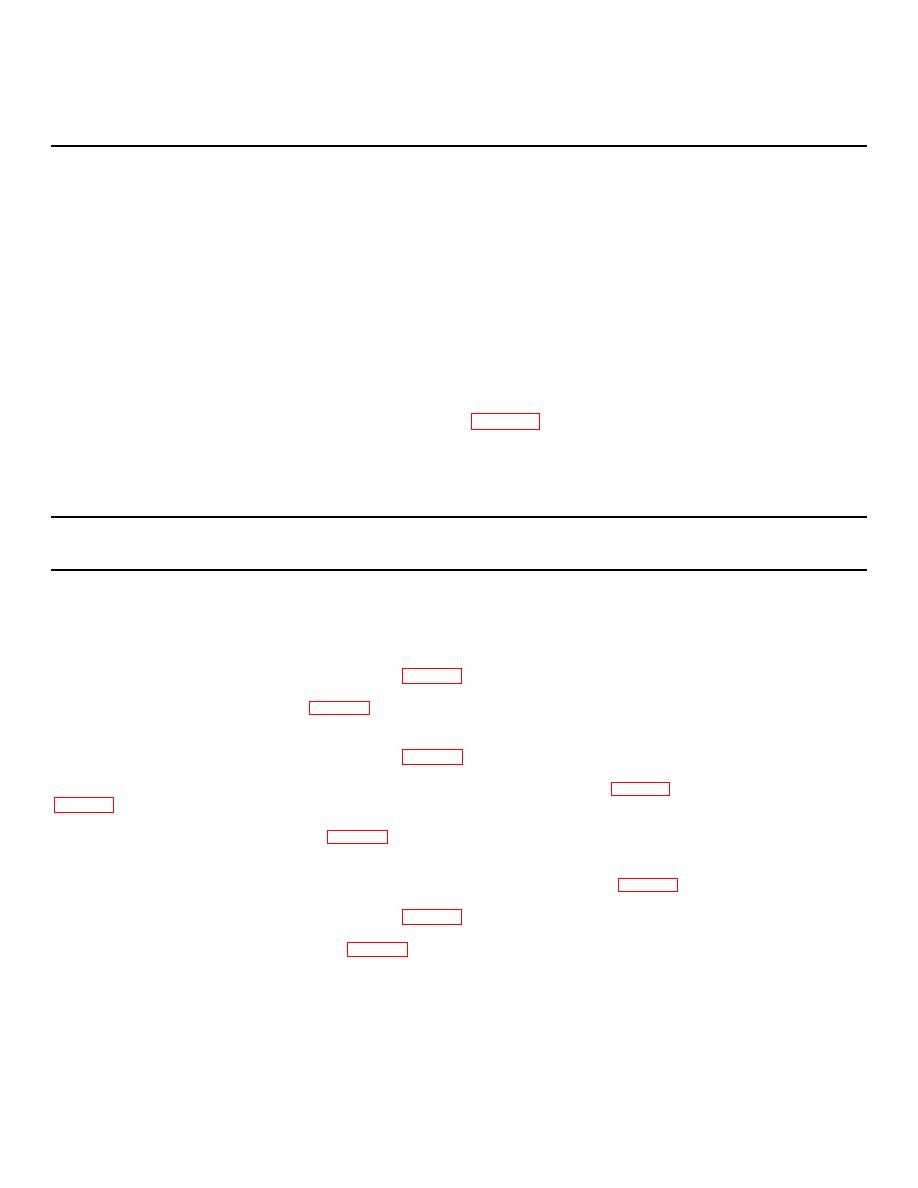

Table 5-1. Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOTE

Before you use this Table, be sure you have performed all normal operational checks. If you have a malfunction which is not listed in

this Table notify your supervisor.

1. COMPRESSOR PUMPING OIL

Step 1.

Check cylinders or piston for wear, scratches or scoring.

Replace defective cylinder or piston (para 6-6).

Step 2.

Check for piston rings broken, or not seated in.

Replace piston rings (para 6-6).

2. KNOCKS OR RATTLES

Step 1.

Check for carbon on top of piston.

Remove air heads and check piston (para 6-6).

Step 2.

Check for loose, broken or carbonized air finger valves.

Separate air heads from spacers and look finger valves over carefully (para 6-6). Replace defective finger valves

Step 3.

Check for worn or scored connecting rod, piston pin, or crank pin bushings.

Replace defective parts (para 6-6).

3. AIR DELIVERY DROPPING

Step 1.

Check for leaking, broken, carbonized or loose finger valves.

Tighten or clean leaking or carbonized valves. Replace defective valves (para 6-6).

Step 2.

Check for scratched, worn or scored cylinders or pistons.

Replace defective cylinder or piston (para 6-6).

Step 3.

Check for piston rings broken or not seated in.

Replace damaged piston rings (para 6-6).

4. MOTOR OVERLOAD RELAY TRIPS

Step 1.

Check line voltage.

Tighten loose connections. Replace defective fuses.

Step 2.

Check for leaking, broken, or carbonized valves, or restricted air passages.

Remove restriction from air passages. Repeat Step 1 of paragraph 3 above.

5-1