TM 5-4310-352-14

secure with screws (17).

c.

Cleaning, Inspection and Repair.

(4) Install front baffle (14), stationary switch

(15) and bearing (16) in front bracket (13) and position

WARNING

front bracket on stator body (23).

Dry cleaning solvent, P-D-680, used to

(5) Install fan (11) and the centrifugal device

clean parts is potentially dangerous to

(12) on shaft of rotor assembly (10) and position rotor as-

personnel and property. Do not use

sembly in stator body.

near open flame or excessive heat.

(6) Install bearing (9) and baffle (8) in rear

Flash point of solvent is 100 (38 ) -

F

C

bracket (7).

138 (59 ).

F

C

(7) Position rear bracket on stator body align-

ing holes in front and rear brackets and secure with studs

(1) Clean all parts except rotor, bearings and

(6) and Nuts (5).

stator in cleaning solvent Fed. Spec. P-D-80 and wipe dry

(8) Install key (4) in keyway of rotor shaft.

with a lint free cloth.

(9) Align keyway in pulley (2) and slide pulley

(2) Use low pressure (25 psi) compressed air

over rotor shaft and secure with setscrew (1).

to clean dust and dirt off rotor, bearings and stator, then

e. Installation. Refer to paragraph 4-9 and install

wipe with a cloth dampened in solvent Fed Spec PD-680.

the motor.

(3) Inspect bearings and rotor shaft for exces-

sive wear, and rough or scored surfaces. Replace defec-

6-3. Motor Starter

tive bearings. Replace a defective-rotor shaft.

a. Removal.

d. Reassembly.

(1) Stop compressor, turn off power, and lock it

(1) Install gasket (21) in conduit box base (22)

out. Refer to figure 6-2 and open cover of motor starter.

and secure base to stator body (23) with screws (20).

(2) Install capacitors (19) in conduit box base.

(3) Position cover (18) over base opening and

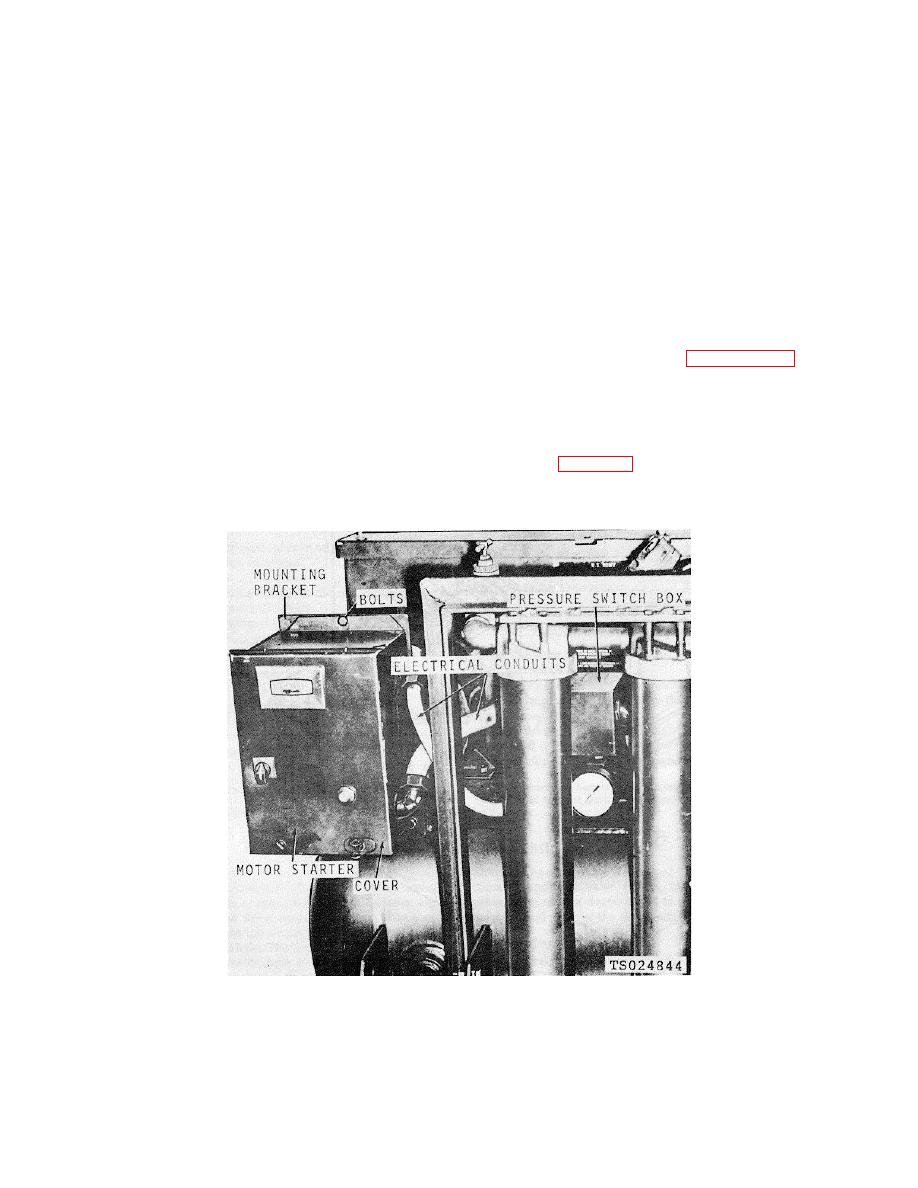

Figure 6-2. Motor starter, removal and installation.

(2) Tag and disconnect all electrical leads.

the

(3) Disconnect the electrical conduits from

6-3