TM 5-4310-354-14

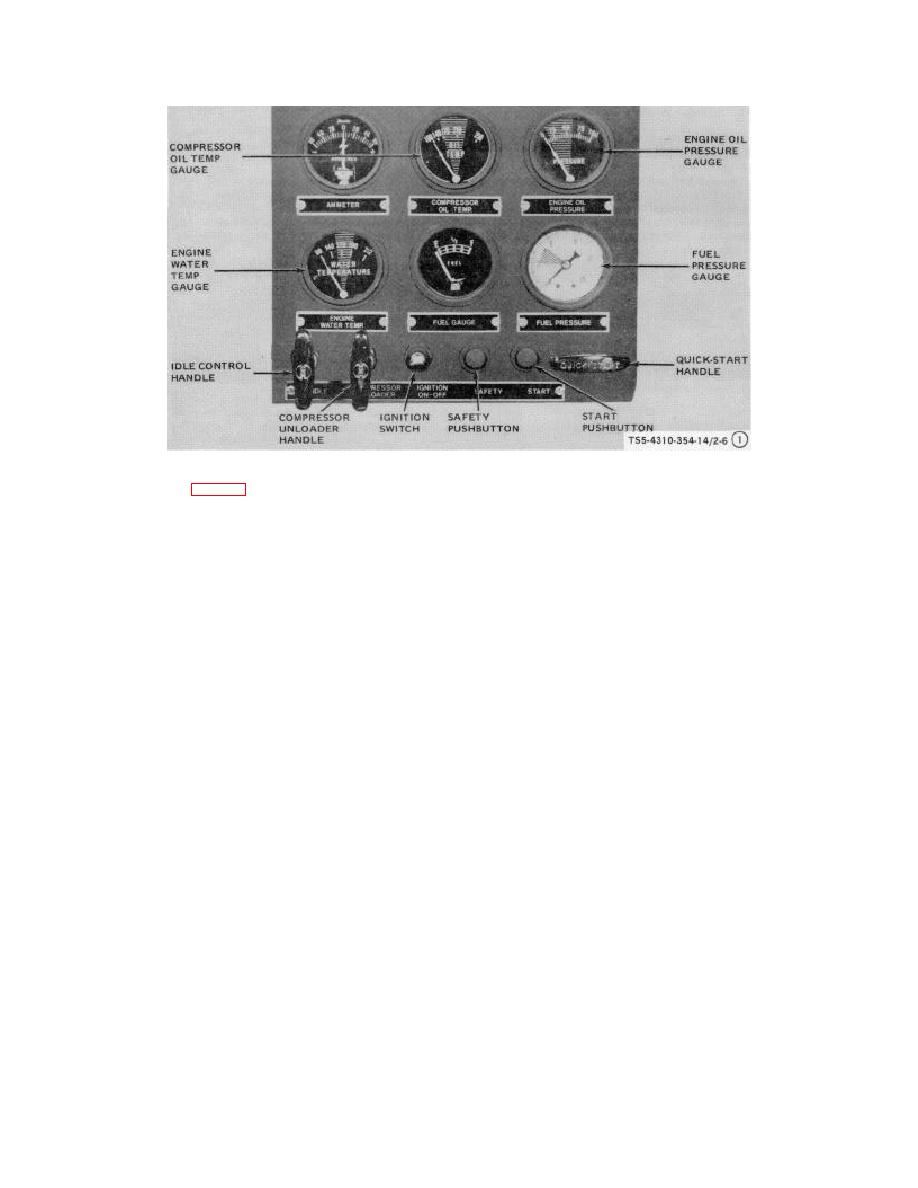

Figure 2-6 Sheet 1

Figure 2-6 Sheet 2

TS5-4310-354-14/2-6 (1)

STEP 1.

CLOSE ALL AIR

DISCHARGE

SERVICE

STEP 6.

RELEASE START PUSHB UTTON AS SOON

VALVES (FIG 2-5).

AS ENGINE STARTS BUT CONTINUE TO

HOLD IN SAFETY PUSHBUTTON. RELEASE

STEP 2.

PRESS START PUSHBUTTON AND HOLD

SAFETY PUSHBUTTON WHEN ENGINE OIL

FOR THREE SECONDS TO CRANK ENGINE

PRESSURE

GAUGE

INDICATES

OIL

TO ENSURE THAT THERE IS NO ENGINE

PRESSURE IS ACHIEVED.

SEIZURE; THEN, RELEASE START SWITCH.

CAUTION

STEP 3.

PULL IGNITION SWITCH TO ON POSITION

(OUTWARD).SWITCH PANEL LAMP SWITCH

IF ENGINE OIL PRESSURE IS NOT

ON, IF NECESSARY, TO ILLUMINATE

INDICATED ON GAUGE WITHIN 3

INSTRUMENT PANEL.

SECONDS AFTER ENGINE STARTS,

RELEASE

SAFETY

PUSHBUTTON.

STEP 4.

TURN COMPRESSOR UNLOADERCONTROL

DETERMINE CAUSE OR

REPORT

CABLE HANDLE COUNTERCLOCKWISE TO

CONDITION

TO

ORGANIZATIONAL

UNLOCK PULL HANDLE OUTWARD UNTIL IT

MAINTENANCE.

STOPS; THEN, TURN HANDLE CLOCKWISE

TO LOCK.

NOTE

STEP 5.

PRESS START PUSHBUTTON AND SAFETY

IF WEATHER IS COOL, BELOW 40F

(4.4oC), PERFORM STEPS 1 THROUGH 4 ;

PUSH BUTTON SIMULTANEOUSLY.

THEN, PULL QUICK-START CONTROL

CAUTION

CABLE HANDLE OUTWARD AND HOLD

OUT FOR 2 TO 3 SECONDS (TO FILL

DO

NOT

CRANK

ENGINE

VALVE CHAMBER).

THEN, WHILE

CONTINUOUSLY FOR MORE THAN 30

PERFORMING STEPS 5 AND 6, PUSH

SECONDS.

ALLOW A 2 MINUTE

QUICK-START HANDLE IN; HOLD FOR 2

COOLING PERIOD BETWEEN STARTING

TO 3 SECONDS IF ENGINE DOES NOT

ATTEMPTS.

IF ENGINE DOES NOT

START IMMEDIATELY, ACTUATE QUICK-

START AFTER A FEWTRIES, DETERMINE

START AGAIN.

CAUSE OR REPORT CONDITION TO

ORGANIZATIONAL MAINTENANCE.

Figure 2-6. Air compressor unit starting procedures (sheet 1 of 2).

2-12