TM 5-4310-354-14

TS5-4310-354-14/2-6 (2)

STEP 7

AFTER ENGINE STARTS, TURN IDLE

CAUTION

CONTROL

CABLE

HANDLE

COUNTERCLOCKWISE TO UNLOCK AND

DO NOT OPERATE THE COMPRESSOR

PULL HANDLE OUTWARD TO INCREASE

UNIT WITH LESS THAN 80 PSI (5.6

KG/CM2) IN THE OIL SEPARATOR TANK.

ENGINE SPEED TO FAST IDLE OF

APPROXIMATELY 1500 RPM.TURN HANDLE

IF AIR DEMAND IS SUCH TO CAUSE

CLOCKWISE TO LOCK. OBSERVE SPEED

PRESSURE TO DROP BELOW 80 PSI (5.6

KG/CM2), REDUCE AIR DEMAND BY

ON TACHOMETER-HOURMETER.

ALLOW

ENGINE TO RUN AT FAST IDLE UNTIL

PARTIALLY

CLOSING

DISCHARGE

ENGINE WATER TEMPERATURE GAUGE

SERVICE VALVE (FIG 2-5).

INDICATES APPROXIMATELY 1400F (600C).

STEP 11.

CONNECT

PNEUMATIC

TOOLS

TO

STEP 8.

UNLOCK IDLE CONTROL CABLE HAND LE,

DISCHARGE SERVICE VALVE CONNECTORS.

PUSH IN HANDLE AND LOCK.

UNLOCK

OPEN THE SERVICE VALVE(S) AS REQUIRED

COMPRESSOR

UNLOADER

CONTROL

FOR TOOLS BEING USED. NORMAL UNIT

CABLE HANDLE, PUSH IN HANDLE AND

OPERATING PRESSURE RANGE IS 80 PSI

(5.6 KG/CM2) LOAD TO 105 PSI (7.4 KG/CM 2)

LOCK.

UNLOAD.

STEP 9.

UNIT IS NOW OPERATING IN THE LOAD

NOTE

CONFIGURATION. OBSERVE AND CHECK

READINGS

OF

ALL

ENGINE

AND

THIS UNIT IS EQUIPPED WITH SAFETY

COMPRESSOR GAUGES.

DEVICES

WHICH

AUTOMATICALLY STOP THE ENGINE

STEP 10.

WHEN UNIT HAS REACHED OPERATING

DUE TO:

HIGH

TEMPERATURE

PRESSURE OF 105 PSI MAXIMUM (7.4

COMPRESSOR

OIL,

HIGH

KG/CM2),

COMPRESSOR

WILL

TEMPERATURE ENGINE COOLANT, LOW

AUTOMATICALLY UNLOAD. UNIT IS NOW

ENGINE OIL PRESSURE, AND ENGINE

READY FOR OPERATION.

OVERSPEED. IF ENGINE STOPS DURING

OPERATION FOR ONE OF THESE

REASONS, DETERMINE CAUSE OR

REPORT

CONDITION

TO

ORGANIZATIONAL

MAINTENANCE

BEFORE ATTEMPTING TO START AGAIN.

ALL SAFETY DEVICES ARE AUTOMATIC

RESET, EXCEPT ENGINE OVERSPEED

WHICH IS MANUAL.

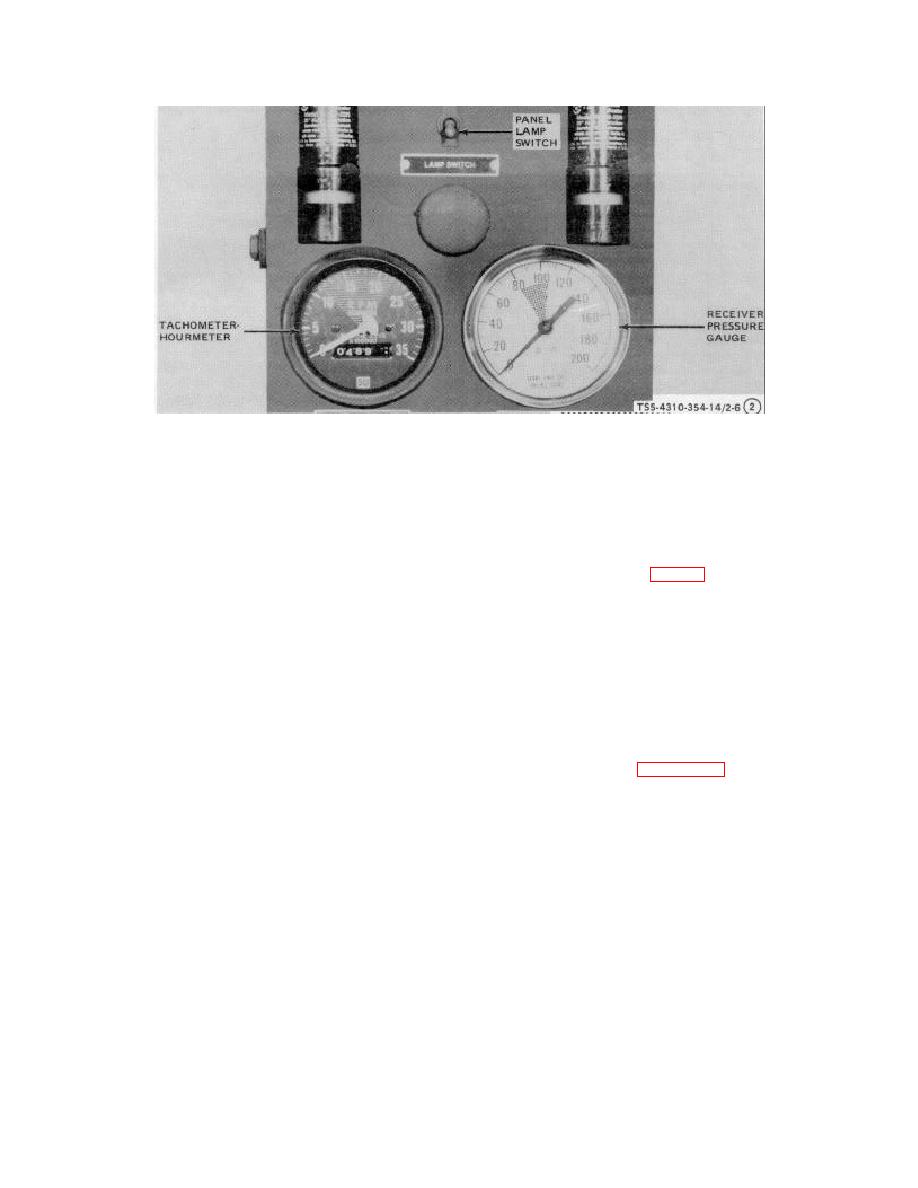

Figure 2-6. Air compressor unit starting procedures (sheet 2 of 2).

2-13