TM 5-4310-356-14

Table 5-1. Troubleshooting (Cont'd)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 3. Check for a defective motor. Connect leads from the motor direct to the power source. If motor

fails to run remove, repair or replace.

a.

Disconnect main power source.

b.

Remove attaching hardware and remove V-belt guard.

c.

Loosen motor mounting bolts, slide motor towards compressor and remove V-belts.

d.

Tag and disconnect electric leads.

e.

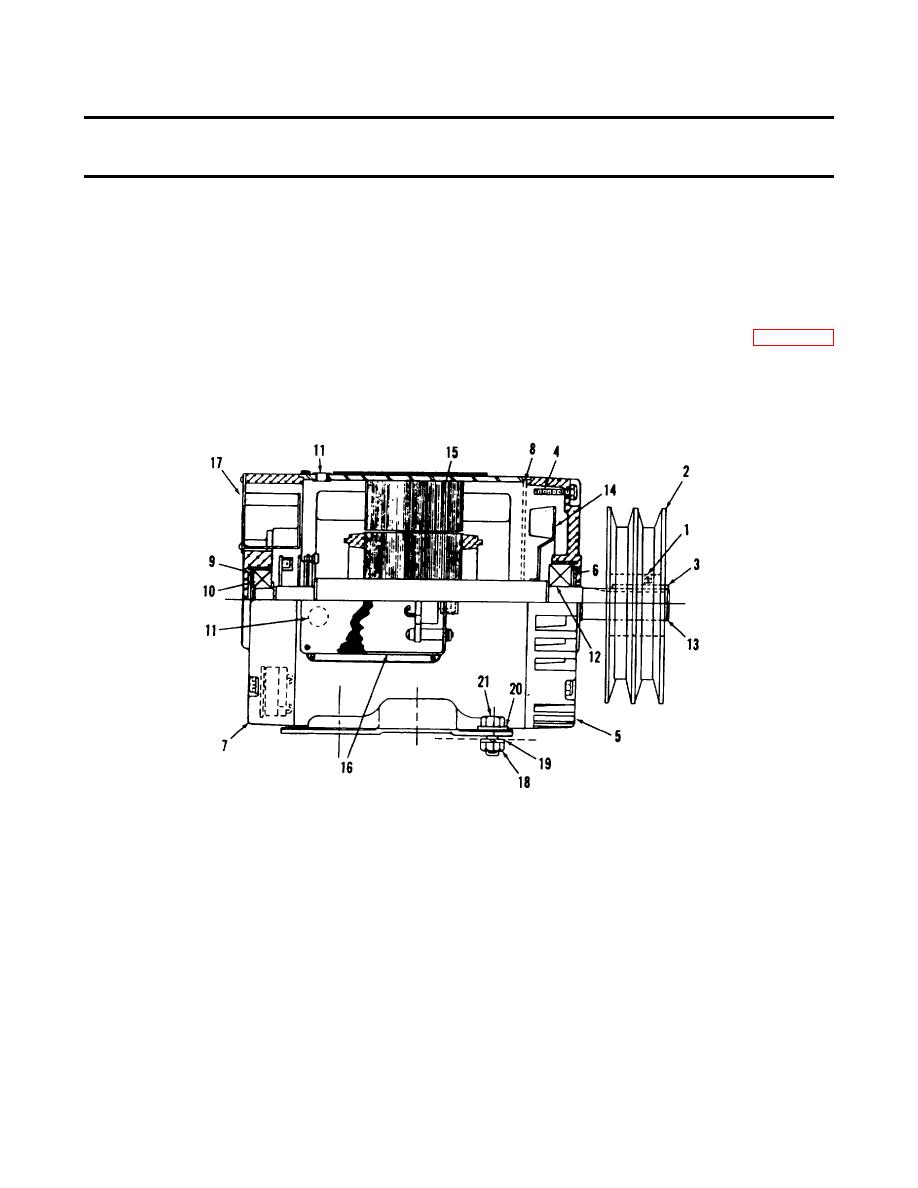

Remove mounting bolts and remove the electric motor and disassemble using figure 5-3

as a guide.

(1) Remove setscrew (1), pulley (2) and key (3).

(2) Remove four bolts (4), rear endbell (5), spring (6), rear bearing (12), baffle (8), front

endbell (7), shim (9), front bearing (10), fan (14), rotor and shaft (13), and stator (15).

1. Set screw, socket

12.

Bearing, rear

2. Pulley

13.

Rotor/shaft assy.

3. Key

14.

Fan

4. Bolt, thru (4)

15.

Frame/stator assy.

5. End bell, rear

16.

Box conduit

6. Spring, wavy

17.

Box, conduit cover

7. Endbell, front

18.

Nut (4)

8. Baffle

19.

Lockwasher (4)

9. Shim

20.

Flat washer (4)

10. Bearing, front

21.

Capscrew (4)

11. Bushing

Figure 5-3. Electric motor assembly.

5-6