TM 5-4310-356-14

Table 5-1. Troubleshooting (Cont'd)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

adjustment is necessary shut off the outside power source.

b. Remove cover from pressure switch.

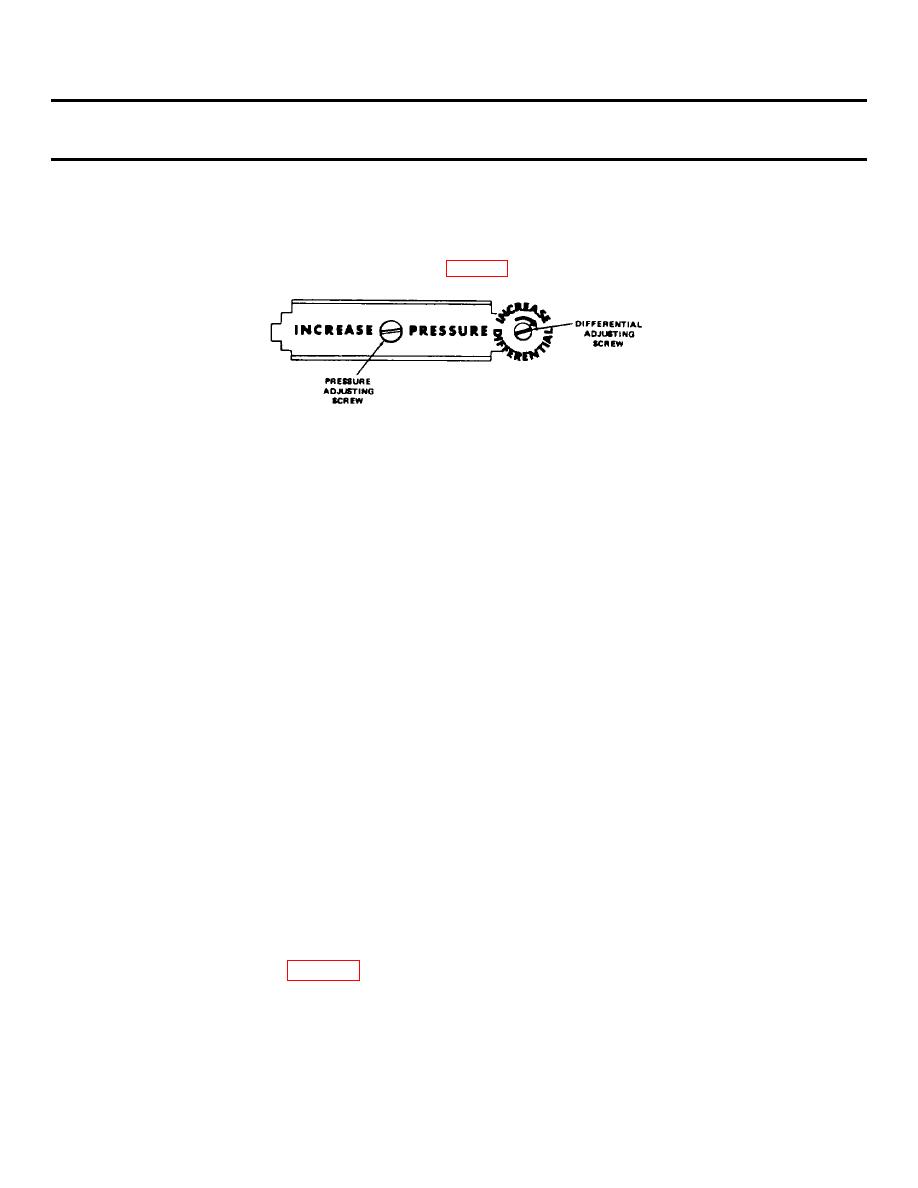

c. To raise the CUT-IN and CUT-OUT pressure turn the pressure adjusting screw

clockwise (fig. 6-5).

d. To decrease the difference between the CUT-IN and CUT-OUT pressure, turn the

differential screw counterclockwise (fig. 5-5).

Figure 5-5. Pressure switch adjustment.

CAUTION

When adjusting the differential screw, do not turn it farther than it will turn easily.

e. To increase the differential and maintain the same CUT-OUT pressure, turn the

differential screw clockwise and, at the same time, the pressure adjusting screw counter-

clockwise.

NOTE

If the differential is increased only by turning the differential screw clockwise, and CUT-IN

pressure changes only slightly, and the CUT-OUT pressure rises.

f. Turn on the outsid e power to check the adjustment. To check the CUT-IN pressure,

open the drain cock and allow air pressure to fall below 165 psi (11.60 kgs). Close the drain

cock and the compressor should start immediately.

g. Install the cover on the pressure switch.

Step 3.

Check for defective pressure switch. If adjustment as outlined in Step 2 above does not help, repair

or replace the pressure switch.

a. Shut off outside power source.

b. Tag and disconnect all electrical leads.

c. Unscrew switch assembly from air receiver.

WARNING

Dry cleaning solvent P-D-680, used to clean parts, is potentially dangerous to personnel and

property. Use in a well ventilated area as the fumes are dangerous if inhaled. Do not use near

open flame or excessive heat. Flash point of solvent is 100 . -138 . (38 . -59 . ).

F

F

C

C

d. Use compressed air and remove all dust and dirt from pressure switch components,

then wipe with a cloth dampened in an approved cleaning solvent.

f. Remove the cover (1), pressure adjusting screw (4), differential adjusting screw and

nut (5), top bar (6), spring equalizer (8), main spring (9), conical spring (3), contact board

assembly (7),toggle spring (10), toggle (11I),-lever (12), plate diaphragm (13), diaphragm (2),

frame assembly (14), and enclosures (15).

g. Inspect the contact board contacts (7) for pitting or burning. Use sand paper to

remove pitting or burning.

5-10