TM 5-4310-362-14

PISTONS, CRANKSHAFT AND CENTRIFUGAL UNLOADER MODEL 20-904 (Cont)

LOCATION/ITEM

ACTION

REMARKS

7.

Connecting rod to

a. Check fit.

crankshaft

(1) Tap cap to make sure

that rod is making

contact.

(2) Tighten both connecting

rod screws and both

lockwashers to 8 ft-lbs.

(3) Combined piston and con-

necting rod should turn

slowly on the crankshaft

of their own weight.

b. If connecting rod to crank-

shaft fit is loose, replace con-

necting rod.

8.

Oil seal

a. Inspect for cuts or damage.

b. Replace if damaged.

8-17.

ASSEMBLY

1.

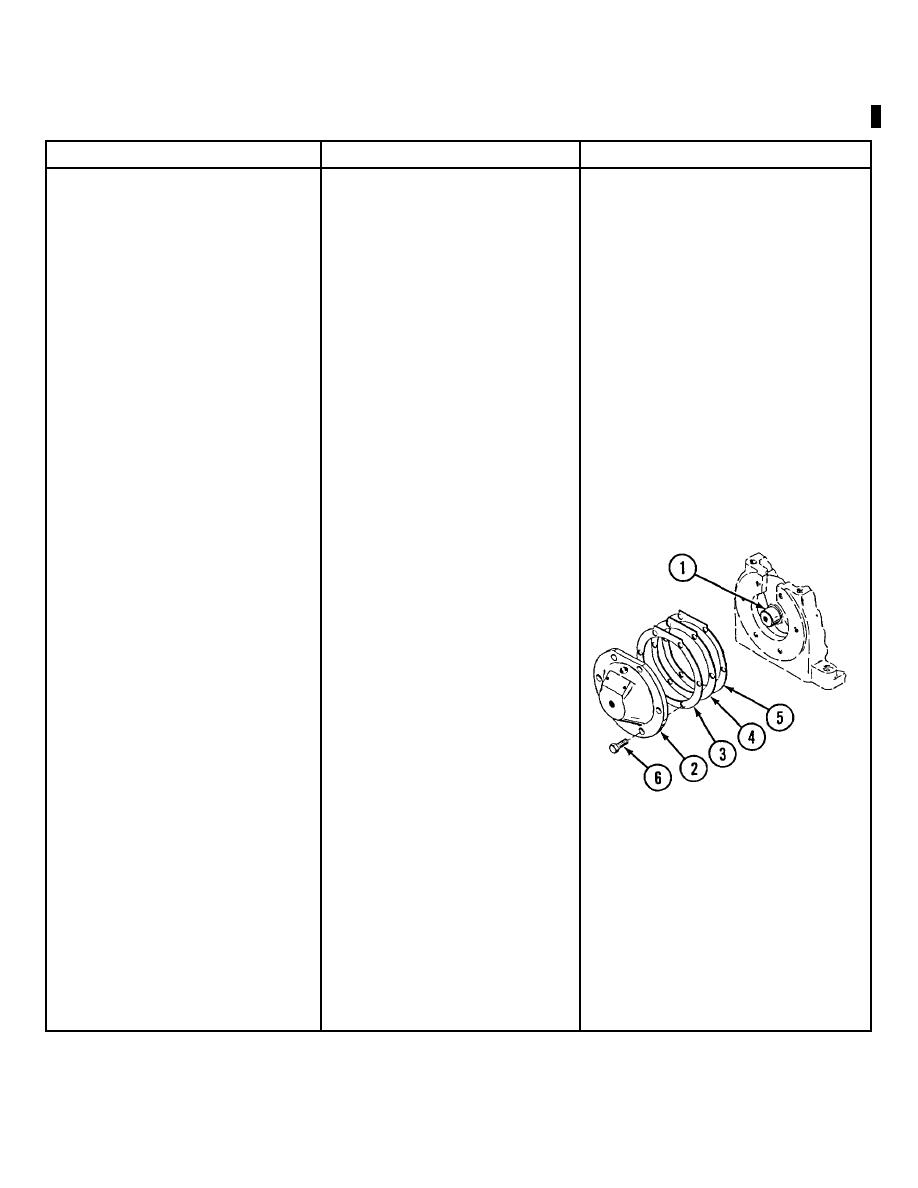

Crankshaft assembly (1)

Install in base.

2.

End cover (2) and

a. Install with six screws (6).

gaskets (3, 4 and 5)

b. Crankshaft should spin in

bearings without end play.

c. Check that oil feeder ring

turns freely within guide lugs

in base.

d. Add gaskets if crankshaft

Too many gaskets will give the crank-

can't be spun.

shaft end play and cause noisy opera-

tion. Too few gaskets will cause the

crankshaft to bind and bearings to

wear out.

e. Remove gaskets to eliminate

end play.

3.

Crankshaft

a. Remove from base.

b. Clamp in soft jaw vise.

Change 1 8-21