TM 5-4310-362-14

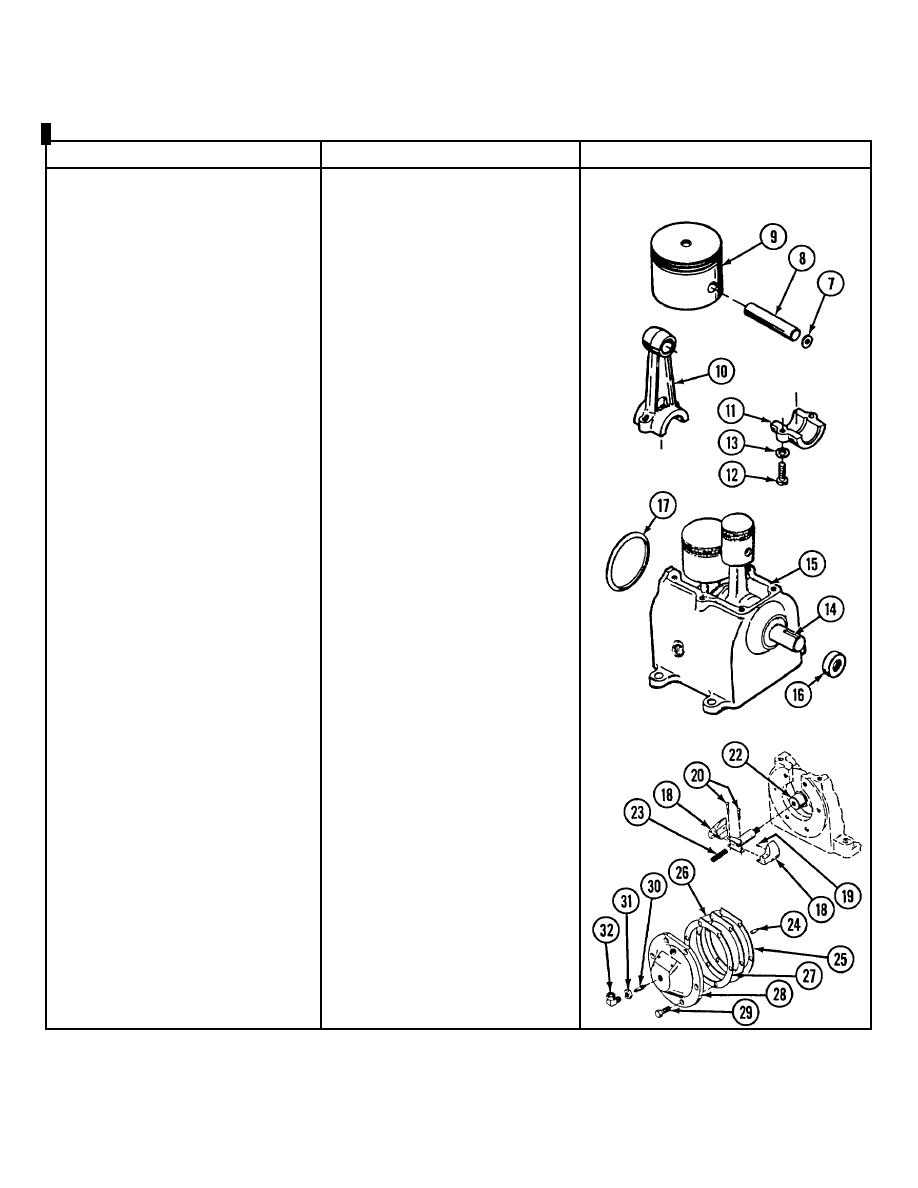

PISTONS, CRANKSHAFT AND CENTRIFUGAL UNLOADER MODEL 20-904 (Cont)

LOCATION/ITEM

ACTION

REMARKS

4.

Wrist pin bearing

If bearing needs replacement,

If bearing is replaced, also replace

line up oil hole in bearing with

wrist pin.

oil hole in connecting rod.

5.

Pistons (9) and connect-

a. Assemble with wrist pin (8).

ing rods (10)

b. Wrist pin should be "tap" fit

by hammer.

6.

Connecting rod to

Tap to make sure rod is making

crankshaft

contact.

7.

Connecting rod cap (11)

a. Install with two screws (12)

and two lockwashers (13).

b. Torque to 8 ft-lbs.

c. Combined piston and con-

necting rod should turn

slowly on the crankshaft of

their own weight if bearing

adjustment is correct.

8.

Crankshaft assembly (14)

Install in crankcase.

with pistons, connecting

rods and oil ring (17)

9.

Oil seal (16)

Install with lip side toward crank-

case (15).

10. Weights (18), springs (19)

Assemble with shaft (21).

and rivets (20)

11. Weight retainer and shaft

a. Install in crankshaft (22) (left

assembly (21)

hand threads).

b. Tighten with a 5/8" open end

wrench. Do not bend wings

of weight retainer.

12. Rivets (20)

Lubricate with OE 10.

13. Spring (23)

Install in shaft (21).

14. Plunger (24)

a. Lubricate with OE 10.

b. Install.

8-22 Change 1