TM 5-4310-369-14

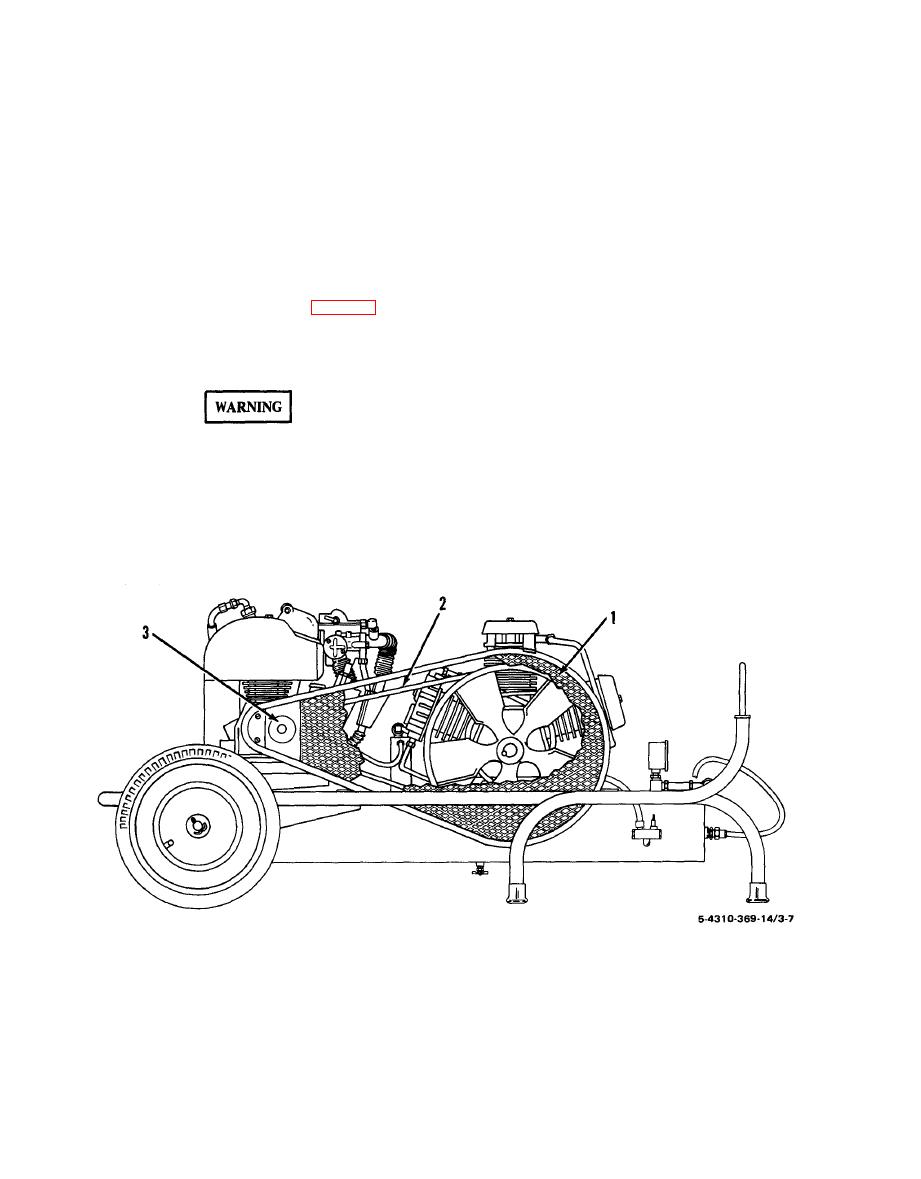

Belt Guard, V-Belts and Pulley

or material wet with drycleating solvent. Wash

a. Inspect the belt guard (1) for dents, cracks, or other

hands immediately after exposure with soap

and water and use a lanolin based skin cream

damage. Straighten minor dents and bends in the guard.

to prevent skin drying. Do not use near open

b. Inspect all attaching hardware for damaged threads.

flame or excessive heat. Flash point of solvent

c. Insepct the V-belts (2) for cuts, fraying and wear.

is 10OF (38C). Ensure that ventilation ade-

d. Inspect the pulley (3) for cracks or looseness and

quate to reduce solvent vapor concentrations

alignment.

below acceptable threshold limit values is

Air Filters

provided.

a. Removal.

(1) Stop the engine.

When using compressed air for blowing, air

hose pressure must not exceed 20 psi, and

cylinder heads by removing bolts securing rain caps to

cylinder heads.

individuals must wear eye protective equipment.

(3) Lift out filter elements (2).

(1) Clean filter element (2) by washing with

b. Cleaning and Inspection.

cleaning solvent P-D-680, blow out with air, and dry

thoroughly.

(2) Replace filter elements if defective.

Drycleaning solvent, P-D-680, used to clean

c. Installation.

parts is potentially dangerous to personnel

(1) Install filter elements into filter housings on

heads.

and property. Avoid repeated and prolonged

skin contact by wearing rubber or solvent

(2) Reinstall air filter rain caps to cylinder heads

impermeable gloves when handling the solvent

with bolts.